Semiconductor device, preparation method thereof and electronic device with semiconductor device

A technology for electronic devices and semiconductors, which is used in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., and can solve the problems of high cost and low output of processing sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

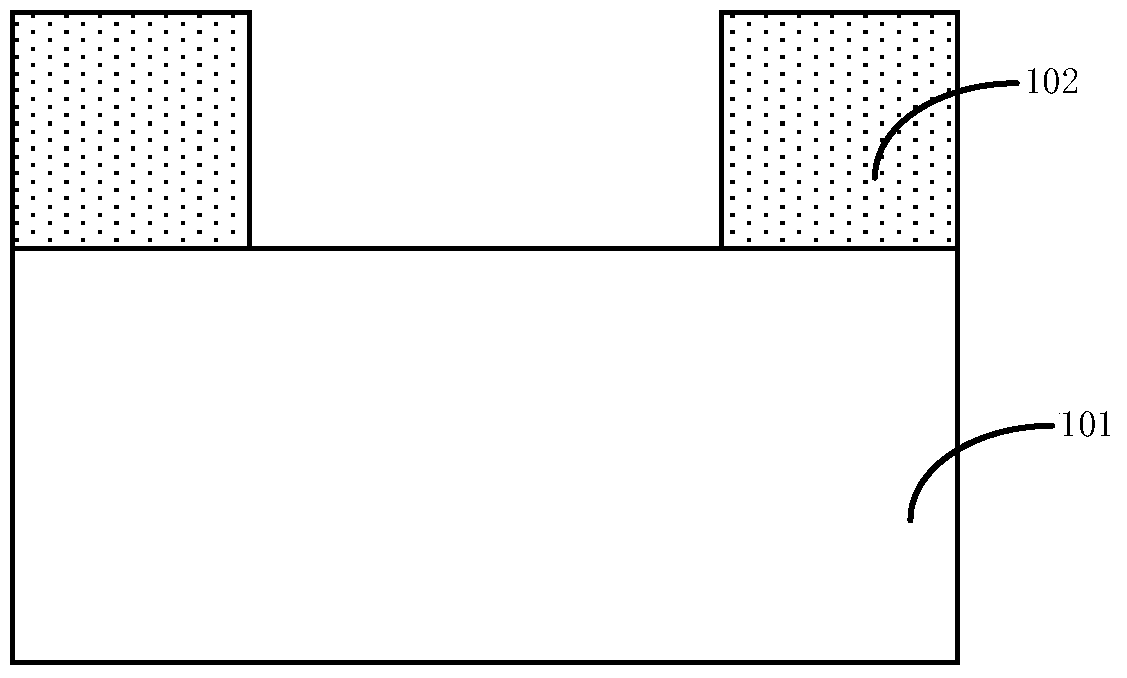

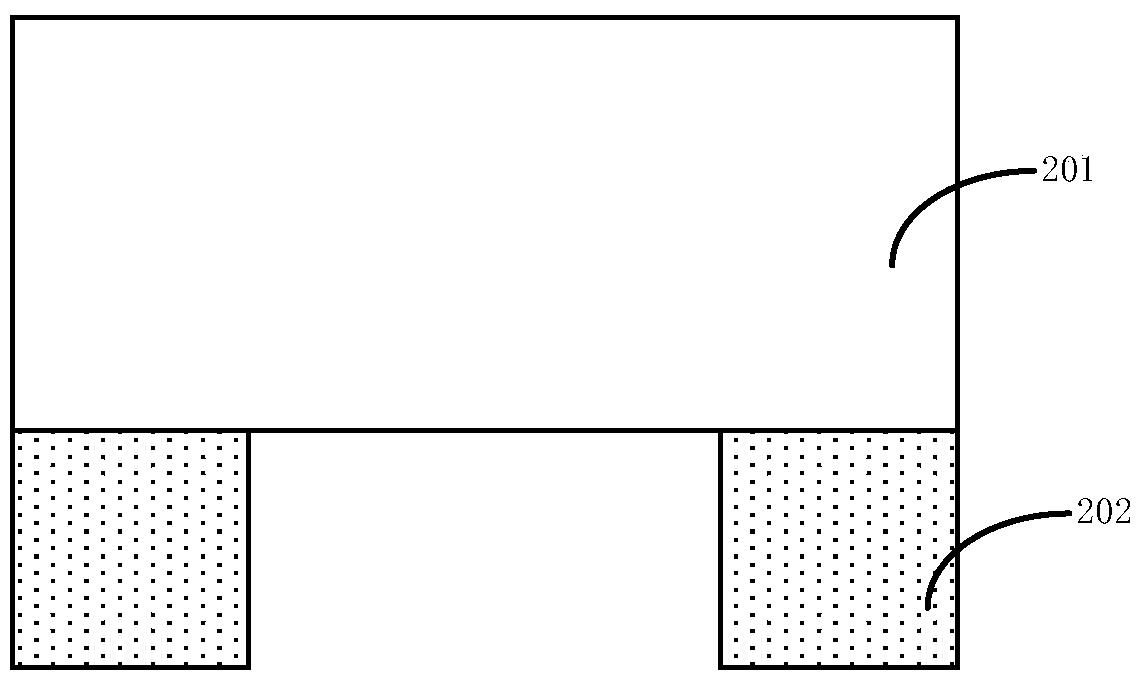

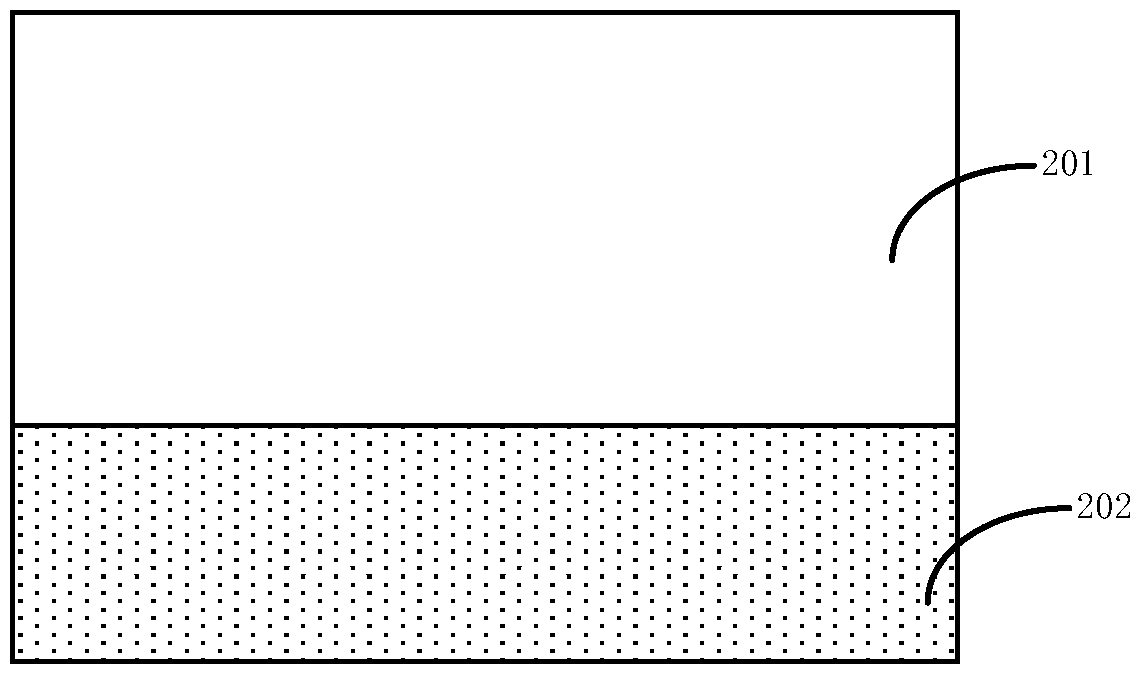

[0050] In order to solve the problems existing in the prior art, the present invention provides a method for preparing a semiconductor device, combined below figure 1 , 2a -2c, and image 3 The method is described further.

[0051] in figure 1 is a structural schematic diagram of the element wafer; Figure 2a-2b is a structural schematic diagram of the supporting wafer; Figure 2c A structural schematic diagram of unbonding the element wafer and the support wafer; image 3 It is a flow chart of the manufacturing process of the semiconductor device described in a specific embodiment of the present invention.

[0052] First, step 201 is performed to provide an element wafer 101 , a first bonding interface layer 102 is formed on the front surface of the element wafer, and a first cavity is formed in the first bonding interface layer 102 .

[0053] Specifically, such as figure 1 Said, components and interconnection structures, such as metal pads, are formed in the component...

Embodiment 2

[0092] The present invention also provides a semiconductor device, which is prepared by the method described in Embodiment 1. The semiconductor device prepared by the method described in Embodiment 1 of the present invention is lower in price, and has higher yield and yield.

Embodiment 3

[0094] The present invention also provides an electronic device, including the semiconductor device described in Embodiment 2. Wherein, the semiconductor device is the semiconductor device described in Embodiment 2, or the semiconductor device obtained according to the preparation method described in Embodiment 1.

[0095] The electronic device of this embodiment can be any electronic product or equipment such as mobile phone, tablet computer, notebook computer, netbook, game console, TV set, VCD, DVD, navigator, camera, video recorder, voice recorder, MP3, MP4, PSP, etc. , can also be any intermediate product including the semiconductor device. The electronic device according to the embodiment of the present invention has better performance due to the use of the above-mentioned semiconductor device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com