A kind of preparation method of light-emitting diode

A technology of light-emitting diodes and electrodes, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low cutting efficiency and high production cost, and achieve the effect of improving cutting efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

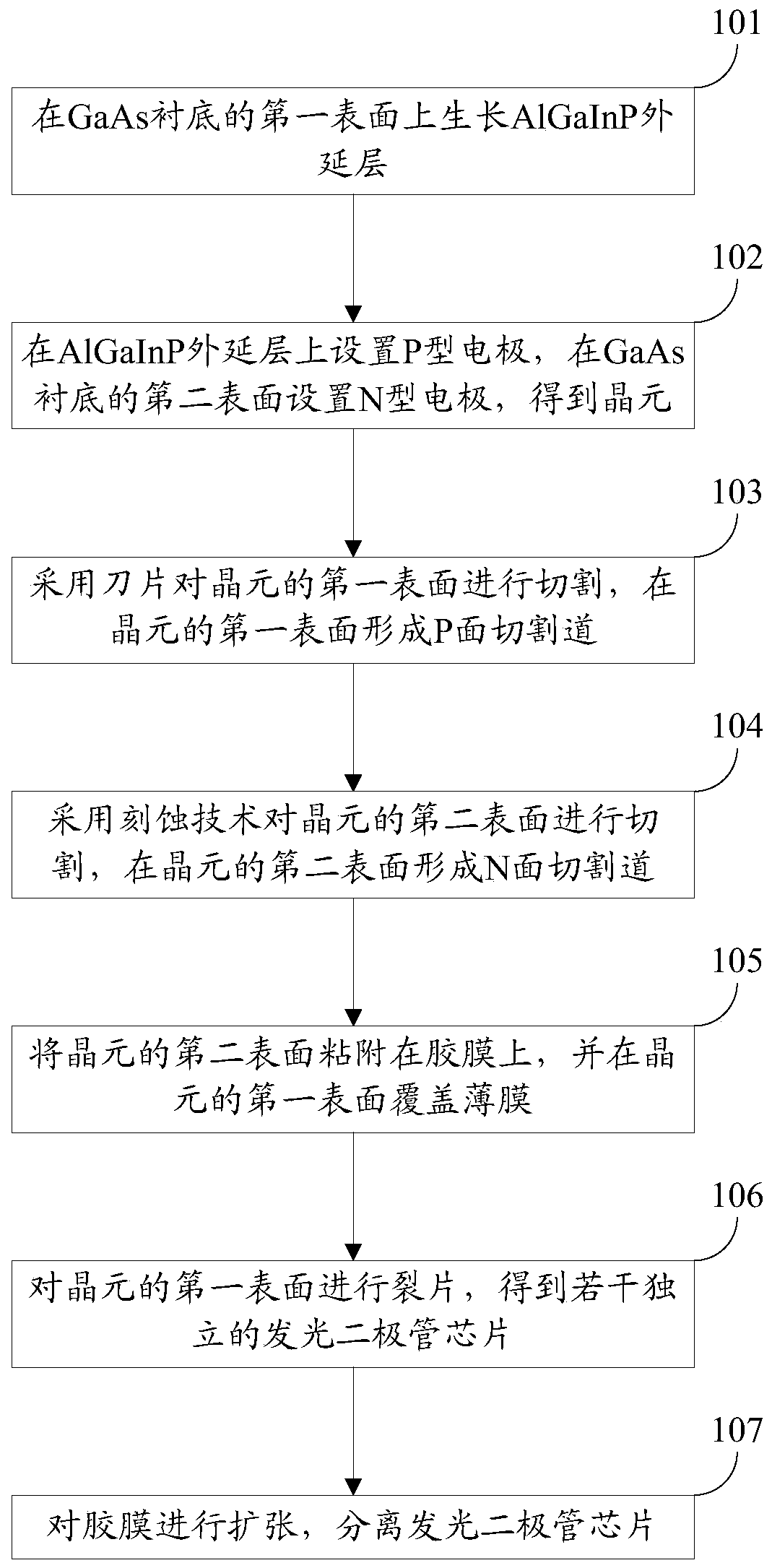

[0043] The embodiment of the present invention provides a method for preparing a light-emitting diode, see figure 1 , the preparation method comprises:

[0044] Step 101: growing an AlGaInP epitaxial layer on the first surface of the GaAs substrate.

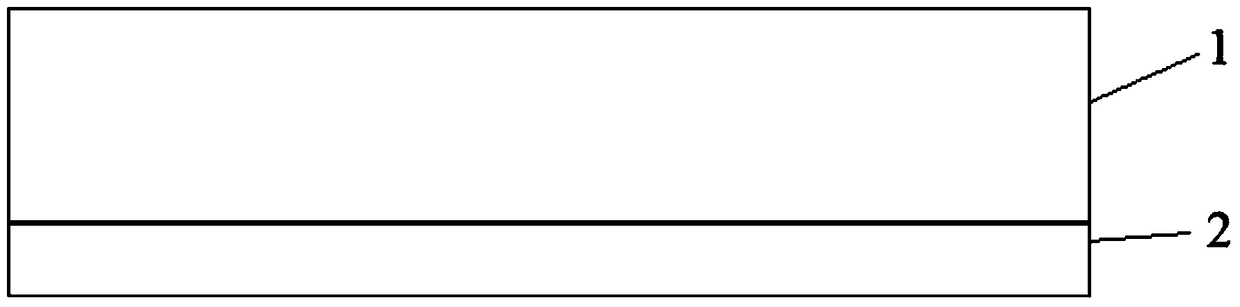

[0045] Figure 2a It is a schematic structural diagram of the light emitting diode after step 101 is executed. Among them, 1 is the GaAs substrate, and 2 is the AlGaInP epitaxial layer.

[0046] In this embodiment, the AlGaInP epitaxial layer may include an N-type AlInP confinement layer sequentially stacked on a GaAs substrate, two alternately stacked AlGaInP multiquantum well layers with different Al compositions, and a P-type AlInP confinement layer.

[0047] Specifically, this step 101 may include:

[0048] An AlGaInP epitaxial layer is grown on the first surface of the GaAs substrate by using Metal-organic Chemical Vapor Deposition (MOCVD for short) technology.

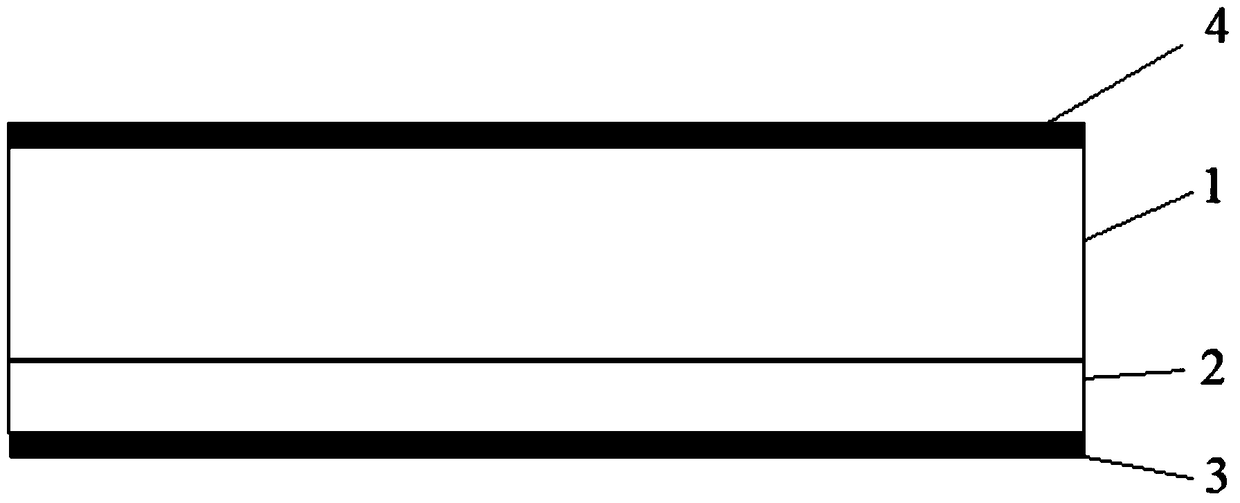

[0049] Step 102: setting a P-type electrode on the AlGaIn...

Embodiment 2

[0102] The embodiment of the present invention provides a method for preparing a light-emitting diode, see Figure 5 , the preparation method comprises:

[0103] Step 201: growing an AlGaInP epitaxial layer on the first surface of the GaAs substrate.

[0104] Figure 6a It is a schematic structural diagram of the light emitting diode after step 201 is executed. Among them, 1 is the GaAs substrate, and 2 is the AlGaInP epitaxial layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com