Machining technological method for cathode vibrating and hitting pin wheel pin of electric dust collector

A processing technology and technology of an electrostatic precipitator, which is applied in the field of the processing technology of the cathode rapping pin wheel pin of an electrostatic precipitator, can solve the problems affecting the dust removal effect, affecting the cathode rapping transmission and cracking of the precipitator, and achieves stable transmission vibration and dust removal. The effect remains stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

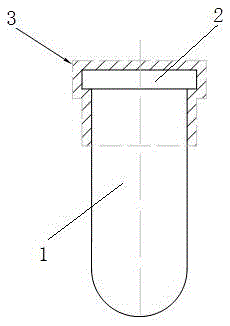

[0011] Such as figure 1 The schematic diagram of the cathode rapping needle wheel pin processing is shown. The cathode rapping needle wheel pin is composed of a pin rod (1) and a pin cap (2). The pin cap (2) and part of the pin rod (1) need to be welded together with the needle wheel disc. In the welding area of the pin cap (2) and part of the pin rod (1), leave a margin of more than 2 mm in the carburizing and quenching zone (3) on one side. The welding zone is covered by the carburizing and quenching zone (3), and the rest is used with a turning tool Turning; after carburizing and quenching treatment, use a turning tool to remove the excess unilateral 2mm of the carburizing and quenching zone (3); weld the pin cap (2) and part of the pin rod (1) of the cathode vibration needle pin ) is integrated with the dial.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com