A single-crystal silicon vertical single-rod square machine

A technology for a square machine and single crystal silicon, applied in the field of single crystal silicon vertical single rod square machine, can solve the problems of time-consuming and labor-intensive gluing, and achieve the effect of solving time-consuming and labor-intensive, low processing cost and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Attached below Figure 1-15 The specific embodiment of the present invention will be further described in detail.

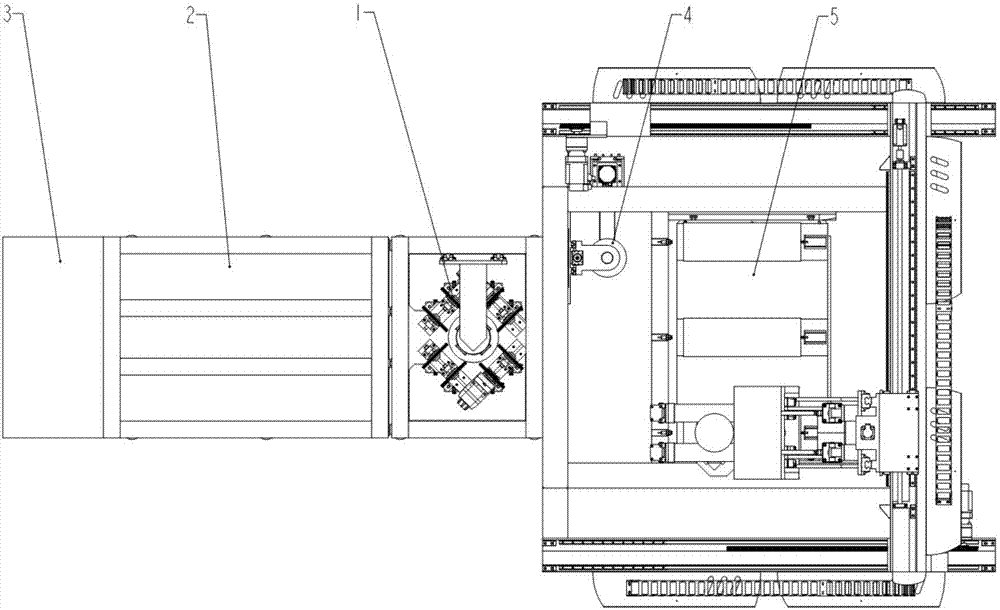

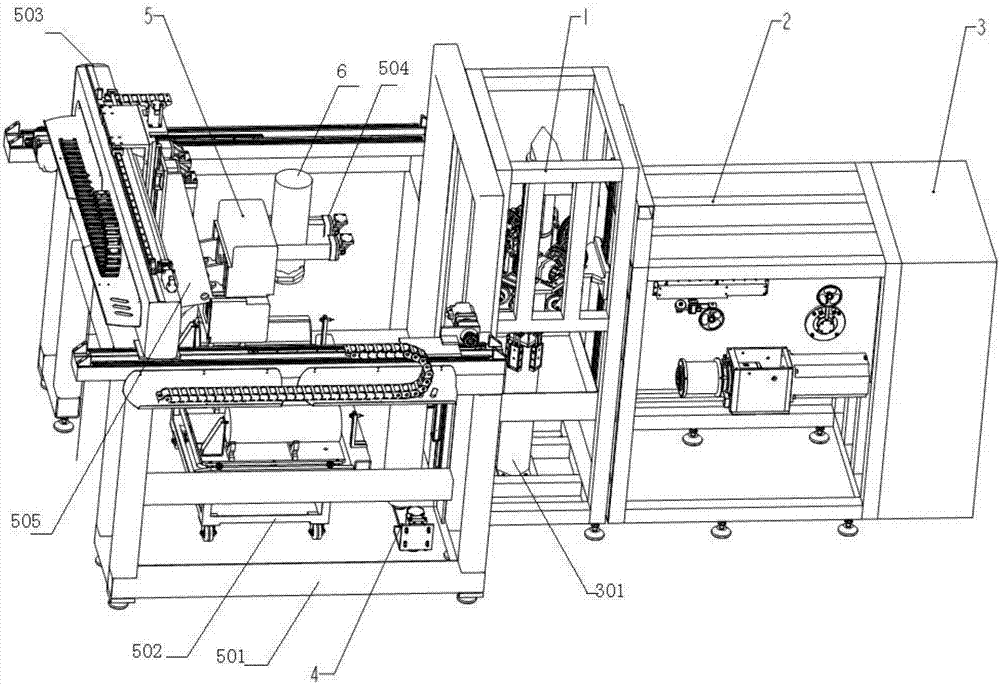

[0042] This embodiment discloses a single-crystal silicon vertical single-rod square cutting machine, such as Figure 1-2 As shown, it includes a cutting room 1 , an electrical room 3 , a wiring room 2 installed on one side of the cutting room 1 , and a crystal wire detection device 4 and a loading and unloading device 5 installed on the other side of the cutting room 1 .

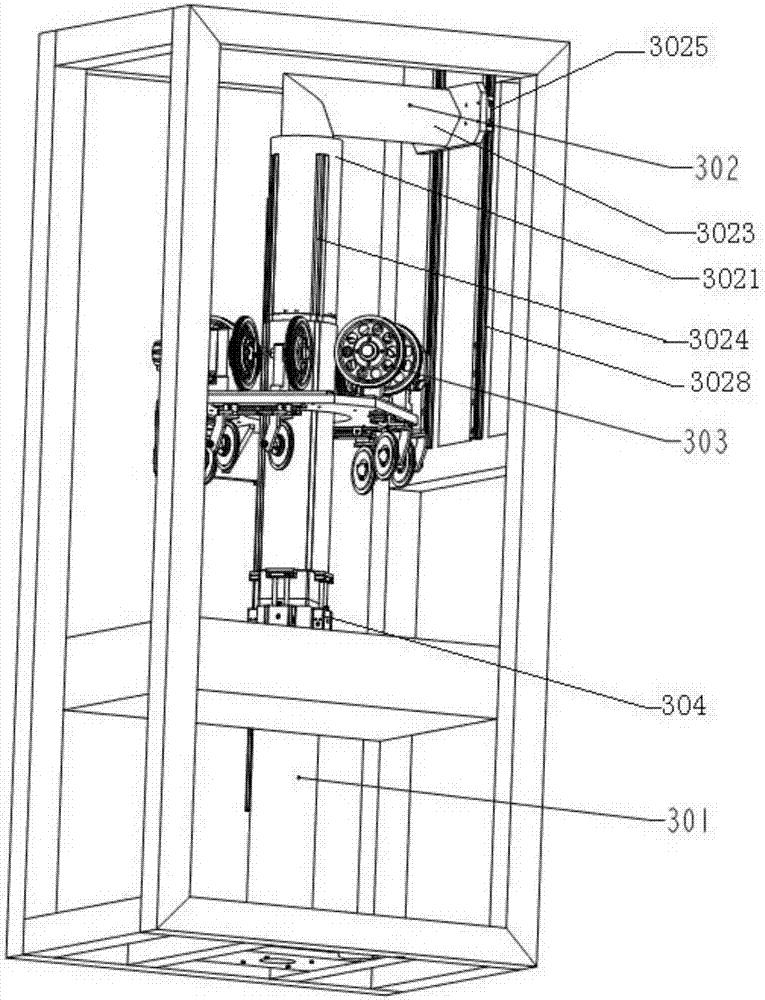

[0043] Cutting chamber 1, such as Figure 3-5 , 15, including a cutting head 303 for cutting a single silicon rod 6, a silicon rod support seat 301 for supporting the lower end of the silicon rod 6 and a silicon rod pressing mechanism 302 for pressing and fixing the upper end of the silicon rod 6 . The silicon rod support seat 301 is installed at the bottom of the cutting chamber 1 to support the lower end of the silicon rod. The silicon rod support seat 301 is provided with four cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com