Circular screen printer with humidification device

A humidification device and printing machine technology, which is applied to screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of unstable printing and dyeing quality, volatile moisture, and large volume of humidification devices, so as to avoid hard strips and dyeing. The effect of unevenness, solving the problem of tops touch-up, and improving the quality of printing and dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

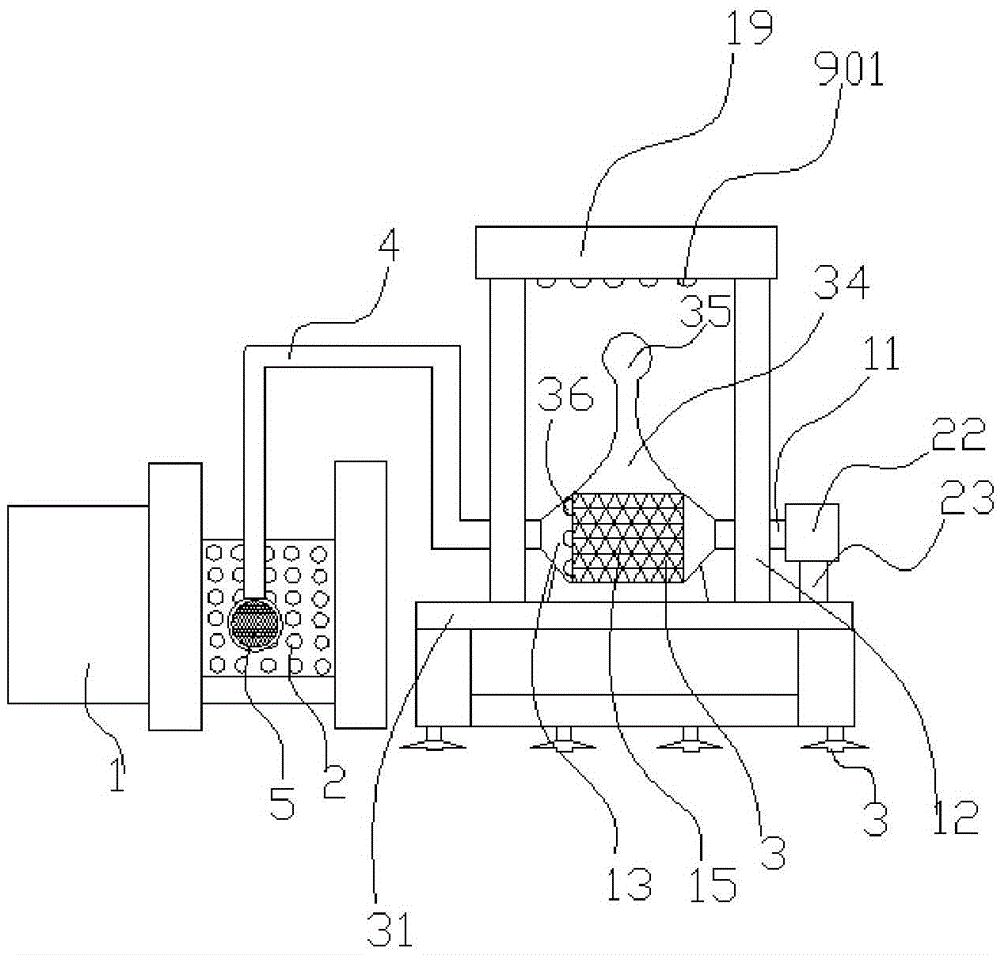

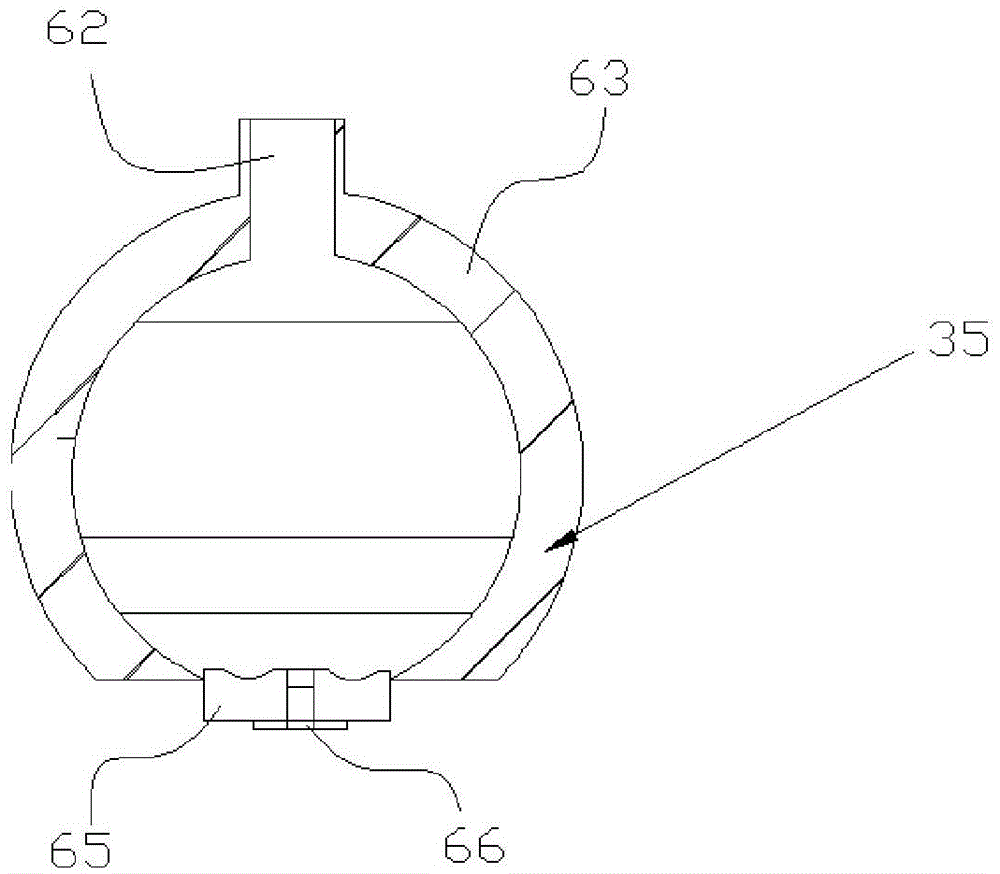

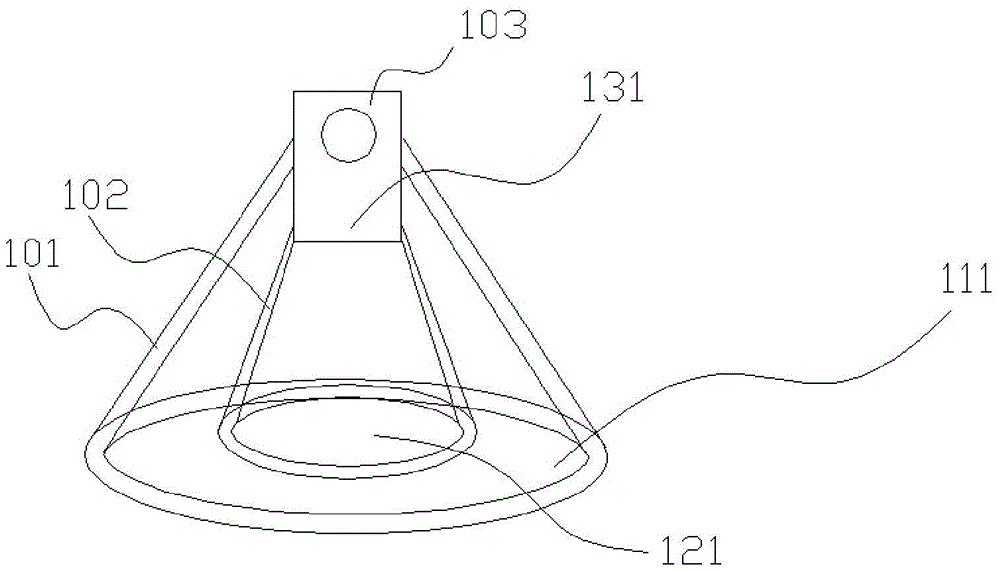

[0021] Such as figure 1 As shown, a rotary screen printing machine with humidification function includes a printing machine body 1, a screen plate 2 arranged on the printing machine body 1, a fixing frame 31 and a humidifying cylinder 3, and the nozzle 5 of the spray pipe 4 is aligned with the screen The board 2, the upper surface of the fixed frame 31 is fixed with a humidification pipeline support frame 12; the humidifier 3 is fixed above the fixed frame 31, and the outer surface of the humidifying cylinder 3 is uniformly provided with a plurality of humidification suction holes 15, and the two ends of the humidifier 3 are provided with There is a roller 13, one end of the humidifying cylinder 3 is provided with a nozzle 4, the other end is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com