Three-dimensional packaging device and three-dimensional packaging method aiming at MEMS

A technology of three-dimensional encapsulation and encapsulation, which is applied in the direction of microstructure devices, processing microstructure devices, and photolithography on patterned surfaces, etc. It can solve the problem of MEMS devices such as sensors and accelerometers that cannot be packaged, and the encapsulation area is large and reliable In order to improve the reliability and production efficiency, the structure of the device is simple, and the processing is precise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

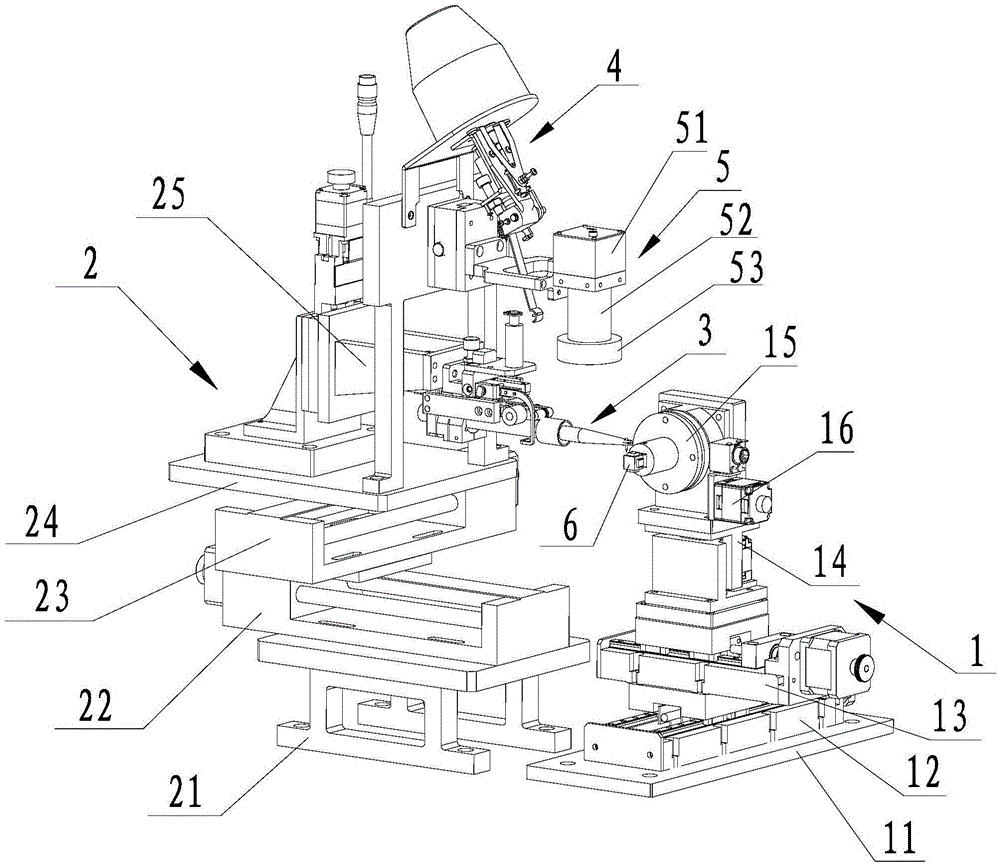

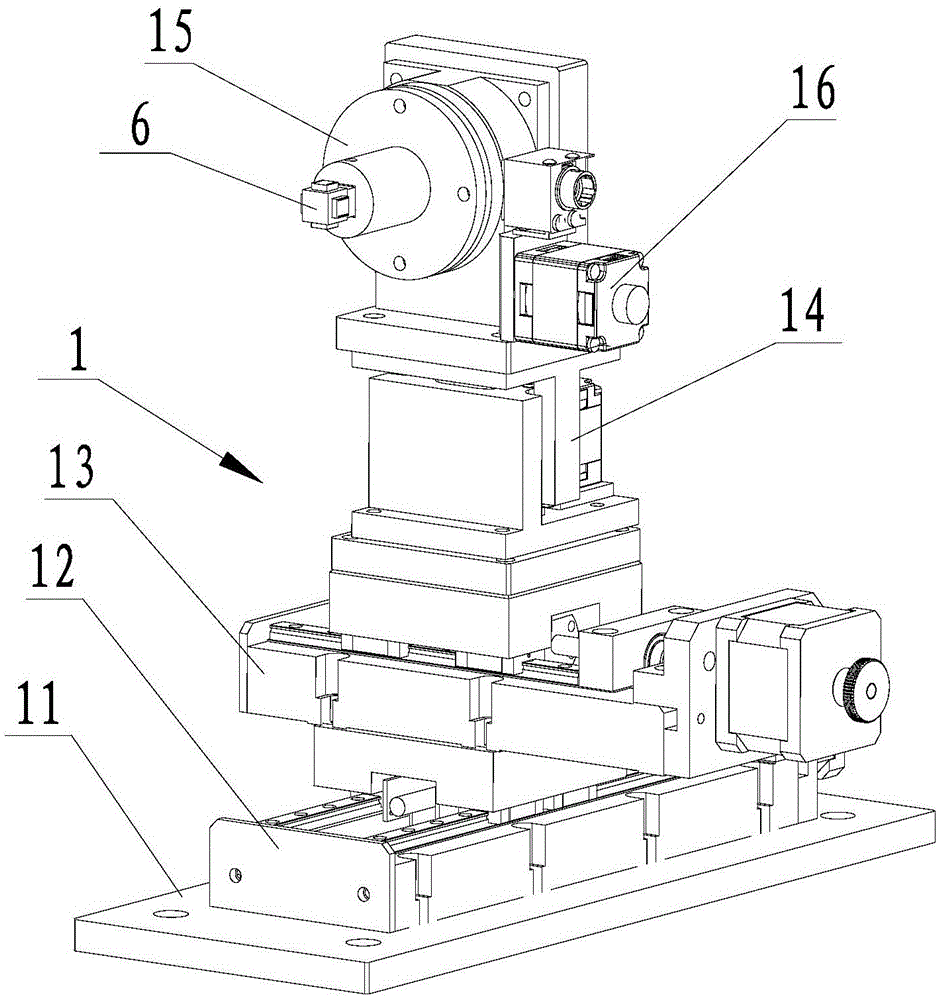

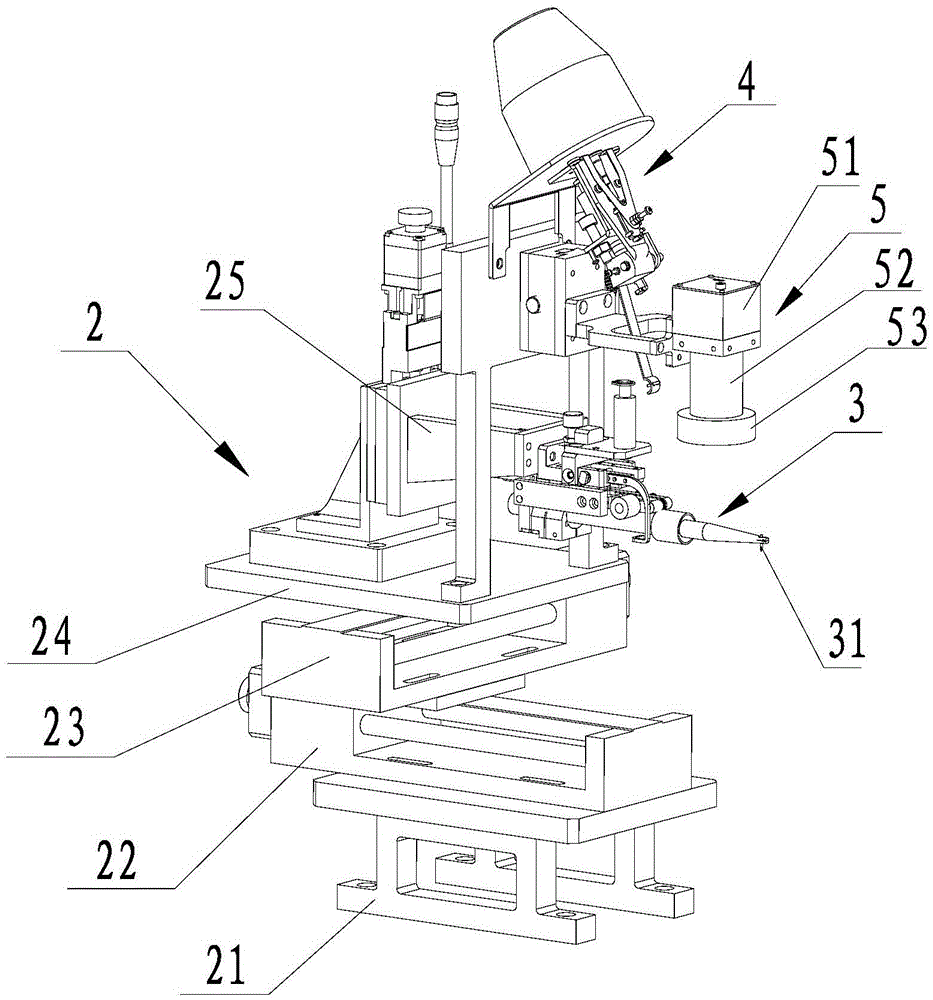

[0040] see Figure 1 to Figure 8 As shown, a MEMS-oriented three-dimensional packaging device includes five parts: a package positioning mechanism 1 , a rivet positioning mechanism 2 , a rivet assembly 3 , a wire feeding assembly 4 , and a microscopic vision assembly 5 .

[0041] see figure 1 , figure 2As shown, the package positioning mechanism 1 includes a first base 11, a mounting seat 14 that can be adjusted along the X, Y, and Z directions relative to the first base 11, and a rotating seat 15 for fixing and installing the package 6. The center line is distributed along the horizontal direction, and the rotating seat 15 is provided on the mounting seat 15 so as to rotate around the center line of the package body 6 . The package positioning mechanism 1 further includes a first driving mechanism for driving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com