Mechanical transmission system of drilling rig winch

A technology of mechanical transmission system and drilling rig winch, which is applied in the direction of mechanical equipment, transmission devices, mechanical control devices, etc. It can solve the problems of heavy casting structure box body, poor adaptability to the environment, and inconvenient structure modification, etc., so as to improve practicability and scope of application, fewer internal defects, and light weight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

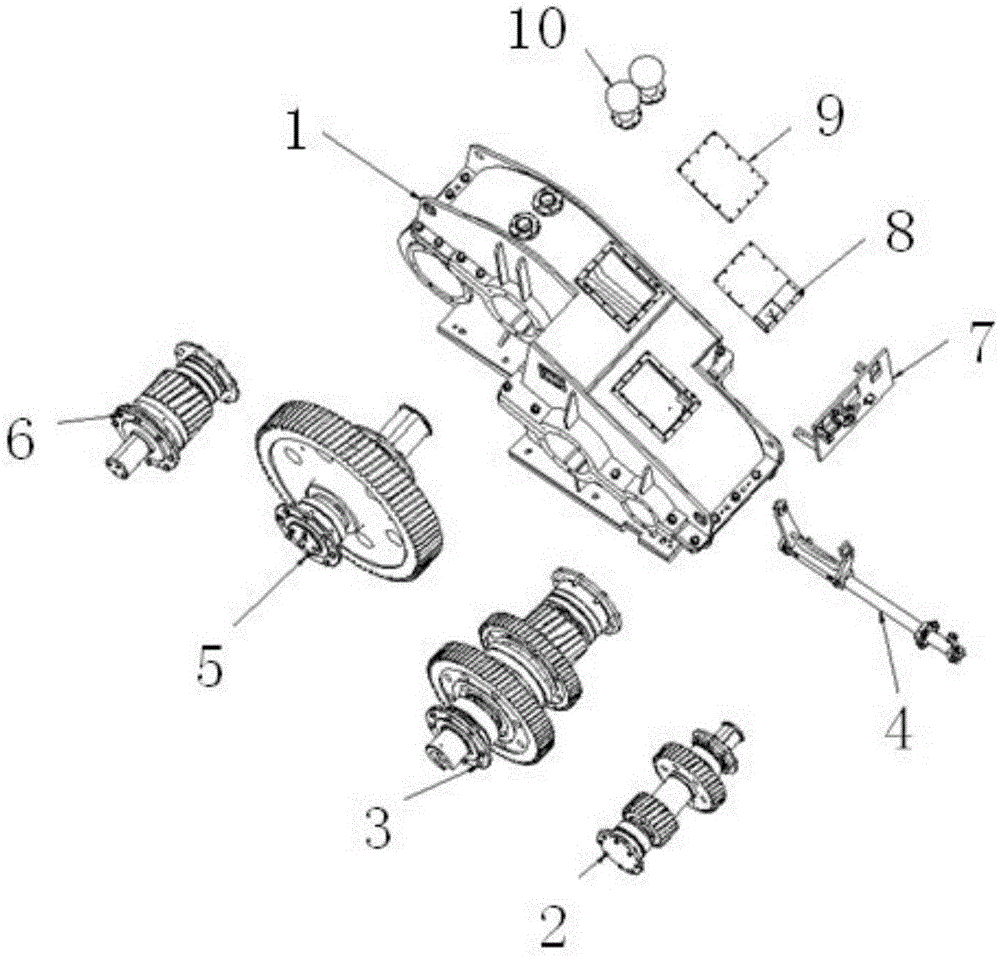

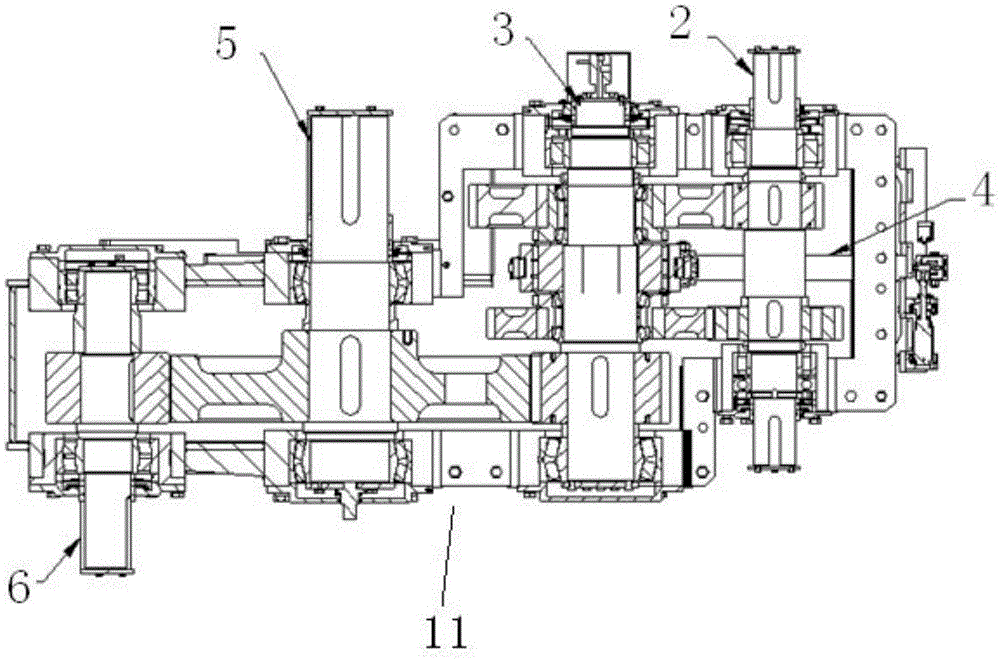

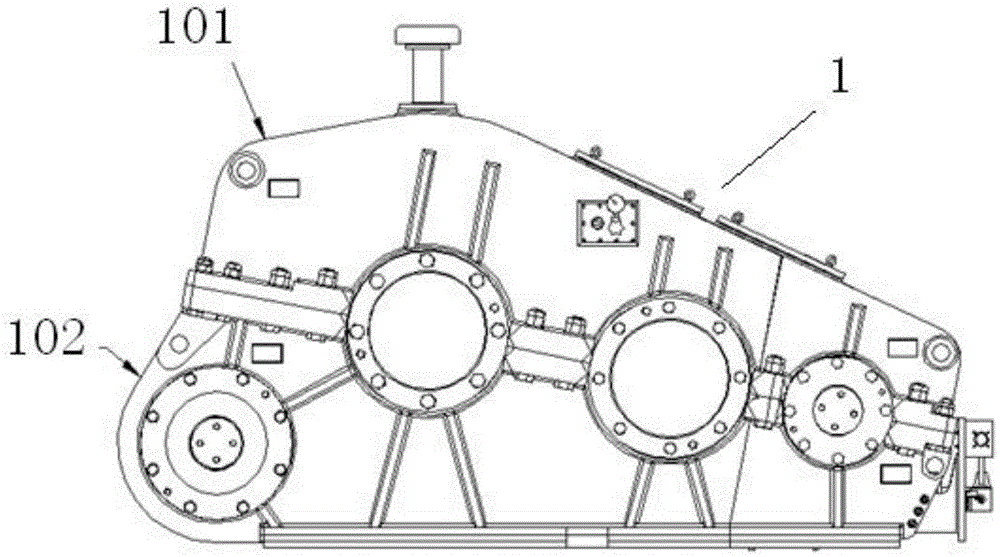

[0079] figure 1 It is a schematic diagram of the overall structure of the mechanical transmission system of the drawworks of the drilling rig; figure 2 It is a structural schematic diagram of the reducer of the mechanical transmission system of the drilling rig drawworks given; image 3 It is a schematic diagram of the structure of the box in the mechanical transmission system of the drilling rig drawworks given; Figure 4 It is a structural schematic diagram of the input shaft assembly in the mechanical transmission system of the drawworks of the drilling rig given; Figure 5 It is a structural schematic diagram of the intermediate shaft assembly in the mechanical tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com