Precise variable mist-spraying test device based on or including electric pump rotating speed regulation

A spray test and electric pump technology, which is applied in the fields of trapping or killing insects, applications, animal husbandry, etc., can solve the problems of long response time, low cost and high cost, and achieves easy modification, compact structure and good versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following is only exemplary and does not limit the protection scope of the present invention.

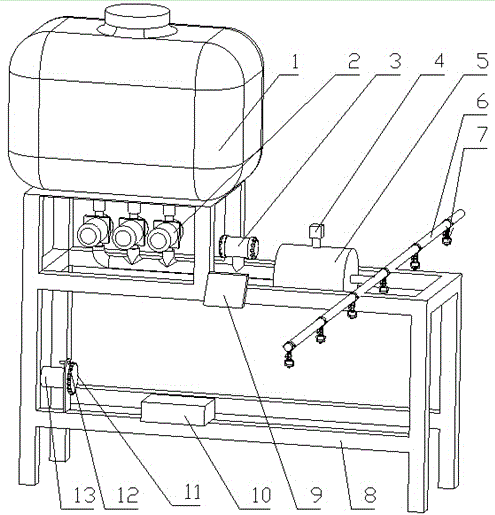

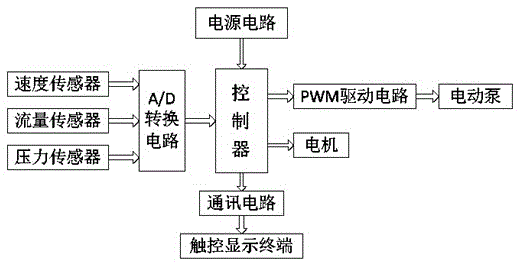

[0029] An accurate variable spray test device based on or including the adjustment of the speed of an electric pump, including a spray parameter acquisition device, an operation speed simulation device, a spray structure, a display device 9 and a controller 10; the operation speed simulation device is used to simulate the operation speed of the spraying unit And collect the operation speed signal, including motor 13, the gear 11 connected with motor 13 and the speed sensor 12 connected with gear 11; , the drug delivery tube 6 is provided with more than one nozzle 7; the spray parameter acquisition device includes a flow sensor 3 arranged at the inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com