Fermenting tower for innocuous treatment to farm waste

A waste and farm technology, applied in the field of fermentation towers, can solve the problems of reducing the amount of tower filling, poor discharge, unfavorable waste gas or foaming gas overflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

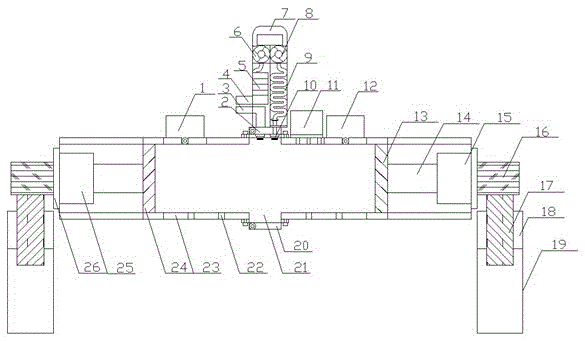

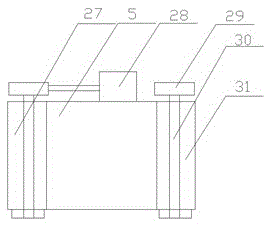

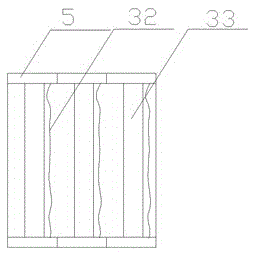

[0035] The present invention will be described below in conjunction with the accompanying drawings. Such as Figure 1-3 as shown, figure 1 It is a structural schematic diagram of the present invention. figure 2 It is a top view of the purified filter material box. image 3 It is a side view of the purified filter material box.

[0036] A fermentation tower for the harmless treatment of farm wastes in the present invention comprises a tower body and two pillars 19, a power head 18 is fixed on the upper part of the pillars 19, an active gearbox 17 is connected to the output shaft of the power head 18, and the tower body is Cylindrical, wherein, the tower body lies between the pillars 19, the outer walls on both sides of the tower body are fixedly connected with fixed discs 26, and the fixed discs 26 are connected with a driven gear box, and the fixed gear box and the driven gear box are connected by transmission. Drive the tower body to rotate slowly at a uniform speed. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com