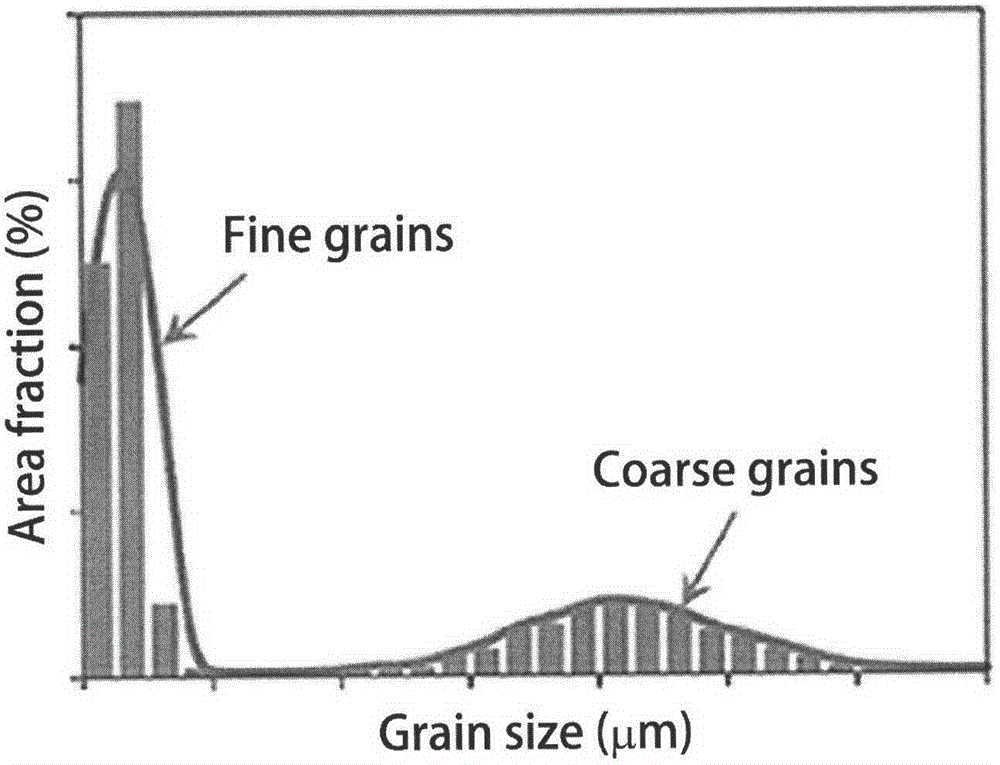

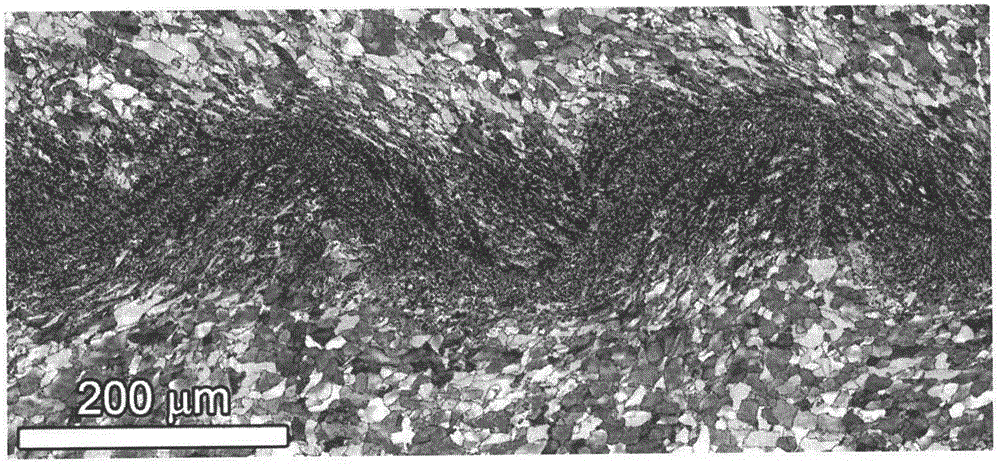

Method of using underwater impact waves to prepare metal material with periodic double-peak distribution structure

A bimodal distribution, metal material technology, used in manufacturing tools, metal processing equipment, welding equipment, etc., can solve problems such as difficulty in obtaining, and achieve the effect of resisting the greenhouse effect and promoting light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The method for preparing a metal material with a periodic bimodal distribution structure according to the underwater shock wave of the present invention will be further described below through specific examples.

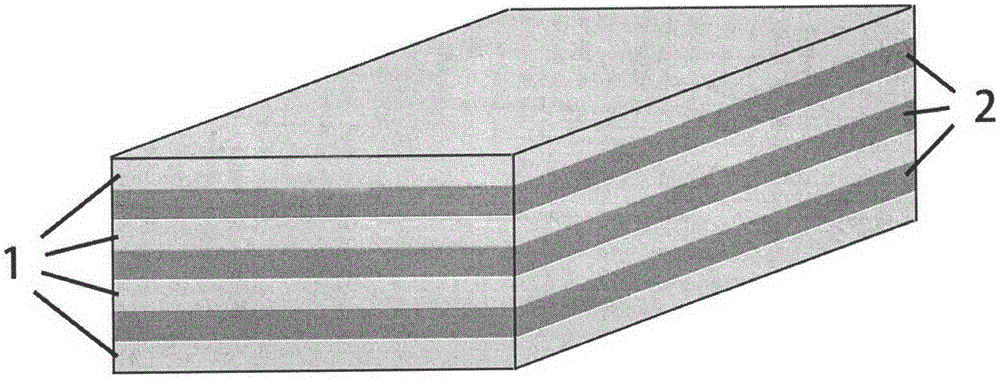

[0030] Such as Figure 7 As shown, a method for preparing a metal material with a periodic bimodal distribution structure by an underwater shock wave is characterized in that the steps of the method are:

[0031] A) Prepare four AZ31 magnesium alloy metal substrates 11 with pre-cleaned surfaces, length 200mm, width 150mm, and thickness 0.5mm;

[0032] Preparation pool 4, with a platform 8 at the bottom of pool 4;

[0033] Prepare support 6, waterproof explosive pack 5, detonator 3, double-sided tape cushion 7 with thickness 0.3mm and width 1mm, waterproof tape 10;

[0034] B) The metal substrate 11 is stacked from bottom to top, and the four sides of each metal substrate 11 are supported by the cushion layer 7, so that a hollow layer 9 is formed between the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com