Multi-station linear polishing machine system

A polishing machine, linear technology, applied in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of being unsuitable for small and medium batch production, difficult to mix production, low production efficiency, etc., and achieve a simple structure. Compact, highly automated, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

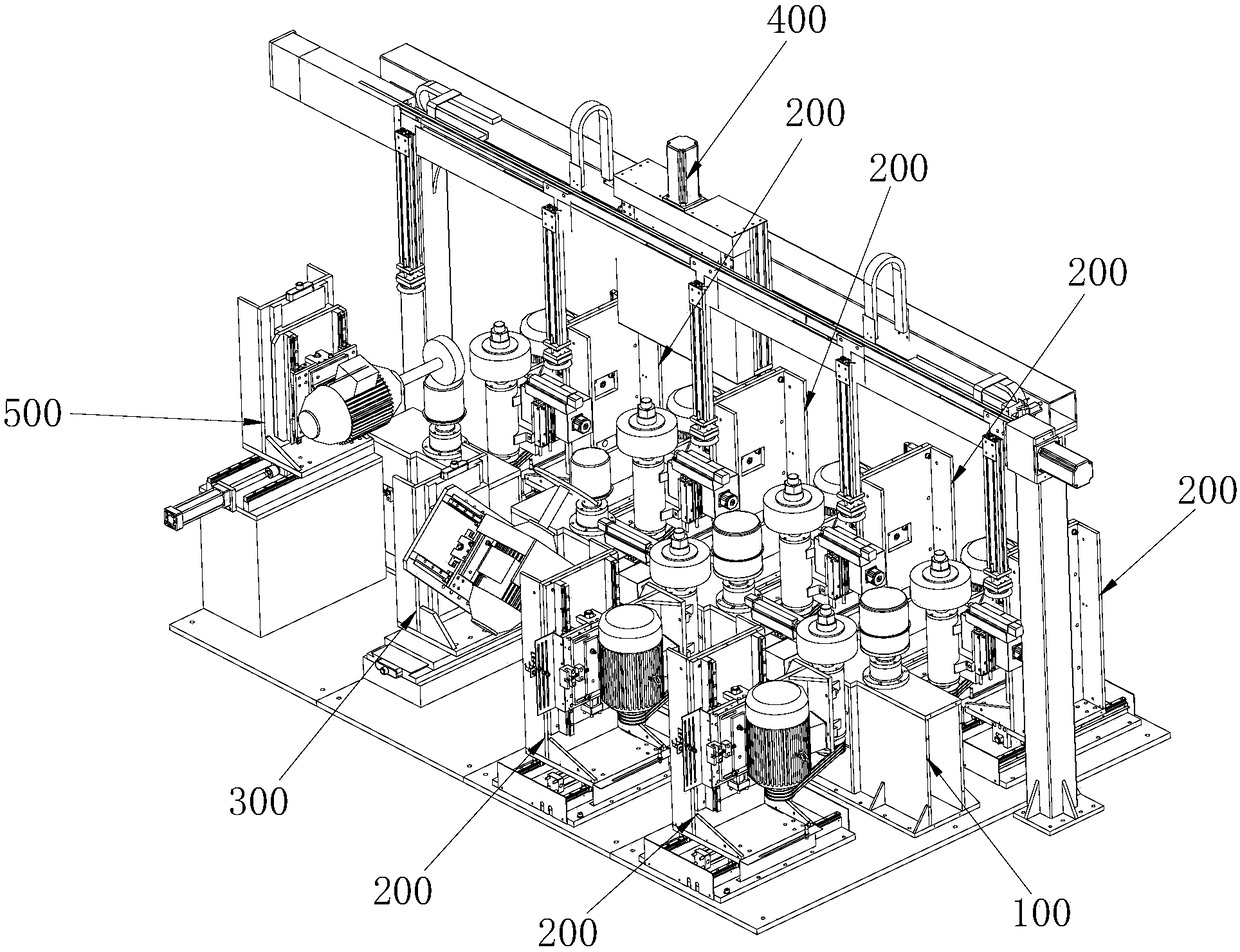

[0047] Refer to Figure 1 to Figure 21 , Is a multi-station linear polishing machine system, which includes:

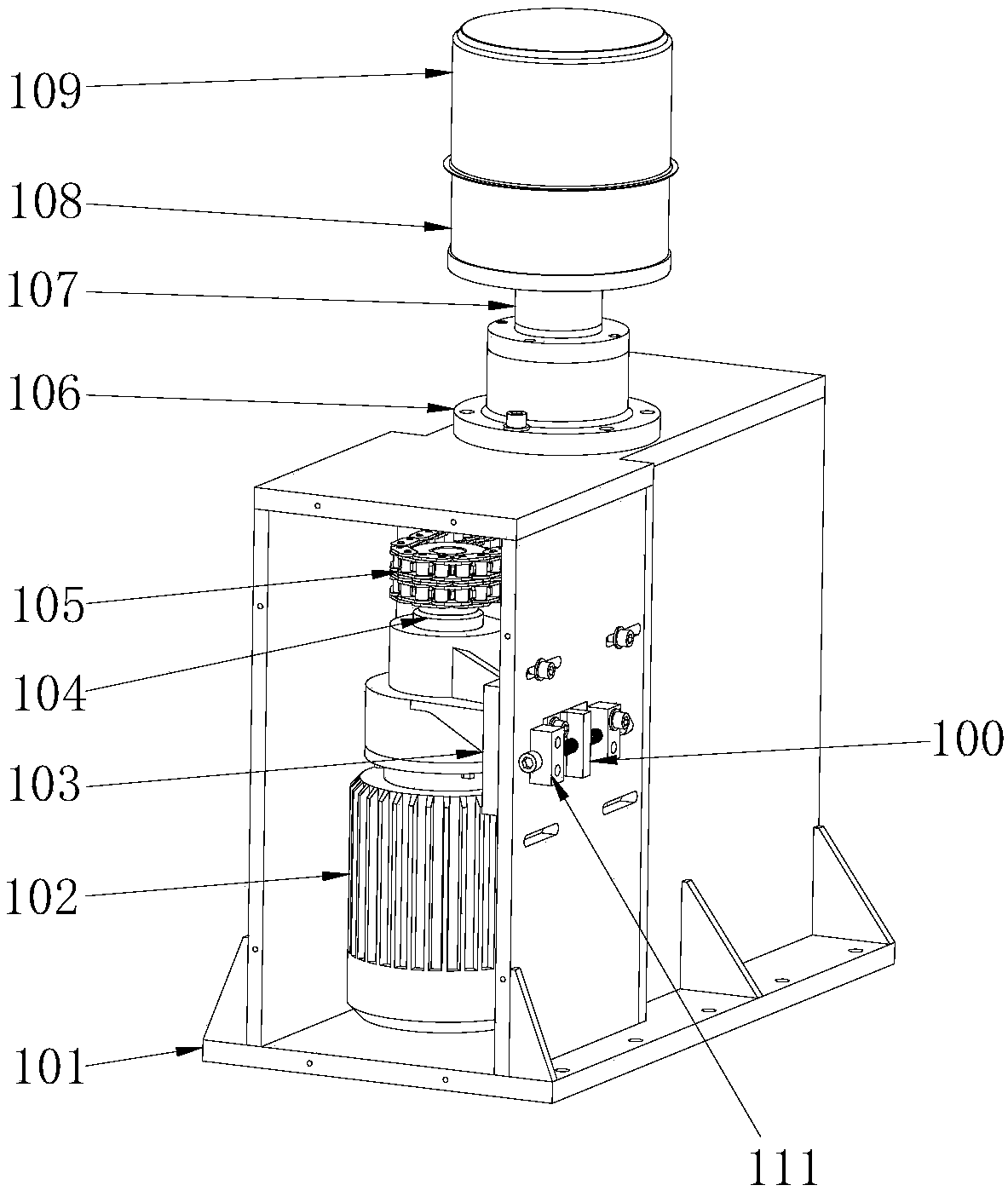

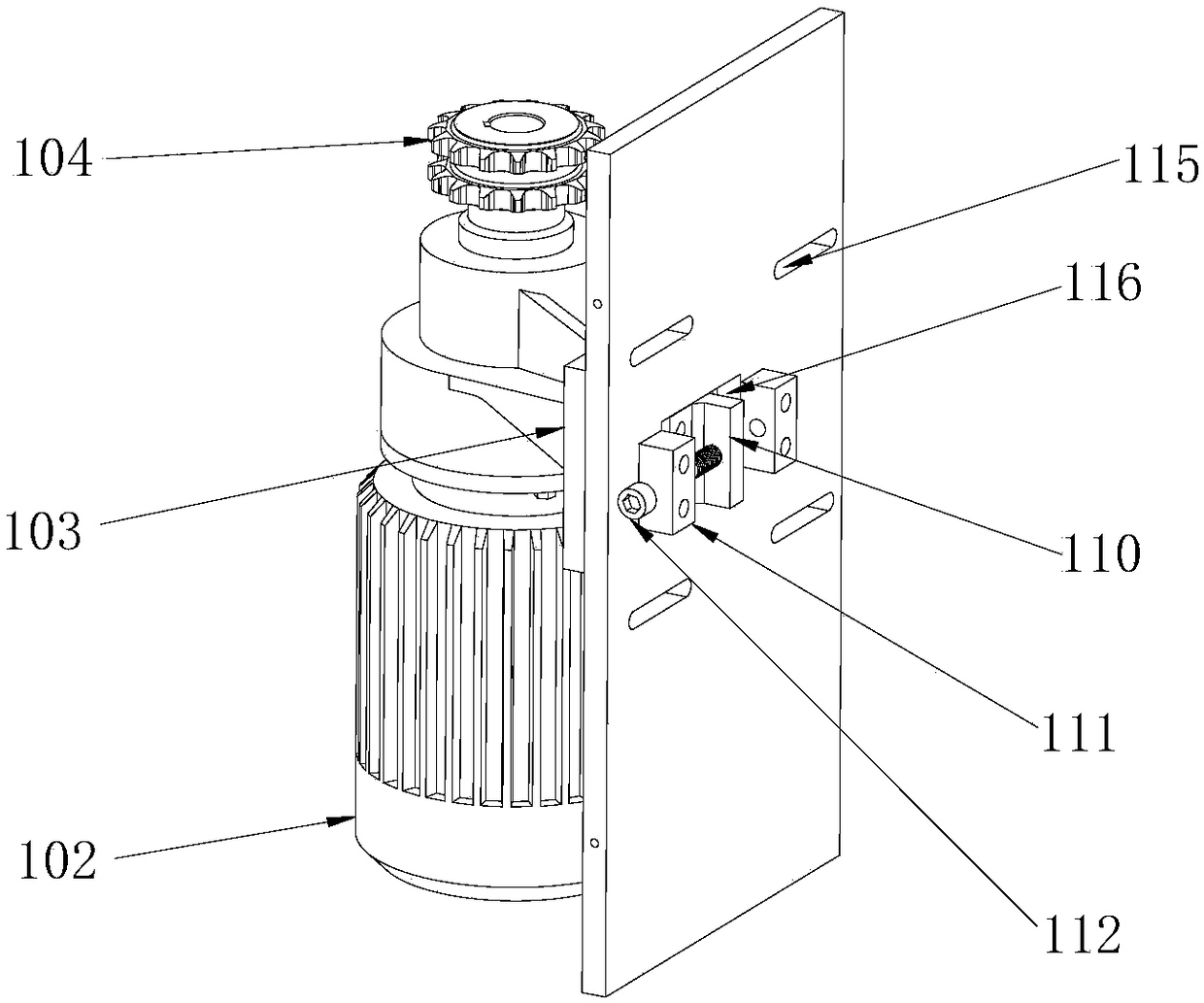

[0048] The die rotating mechanism 100 includes a rotating die 108 for adsorbing the stainless steel pot 109 to be processed on the rotating die 108, and adjusting the rotating speed of the die according to the process requirements to make it meet the requirements of polishing quality;

[0049] The main mechanism of the polishing machine includes the outer body-negative multifunctional polishing unit 200, the reverse side polishing unit 300, and the bottom polishing unit 500. The above-mentioned polishing units are equipped with polishing wheels. Different types of polishing units have different types of polishing wheels. By adjusting the position and angle of the polishing wheel, the stainless steel pot 109 to be processed on the rotating die head 108 is cut to meet the polishing process requirements;

[0050] The modular structure of the polishing machine is composed of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com