Method for synthesizing CoAPO-41 molecular sieve

A technology of coapo-41 and molecular sieve, which is applied in the direction of molecular sieve compounds, molecular sieve characteristic aluminum phosphate, molecular sieve and alkali-exchanged phosphate, etc., can solve the problem of orifice or channel blockage, shorten the crystallization time, and inhibit carbon deposition and deactivation , Mild and acidic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

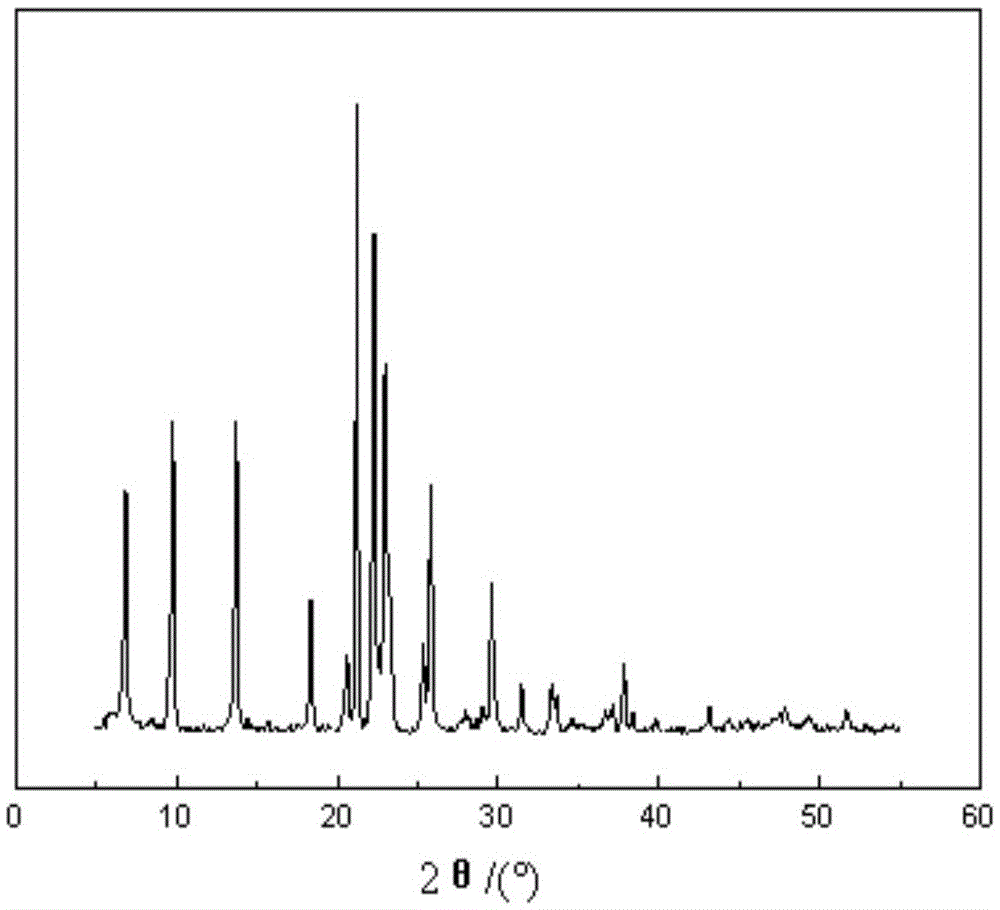

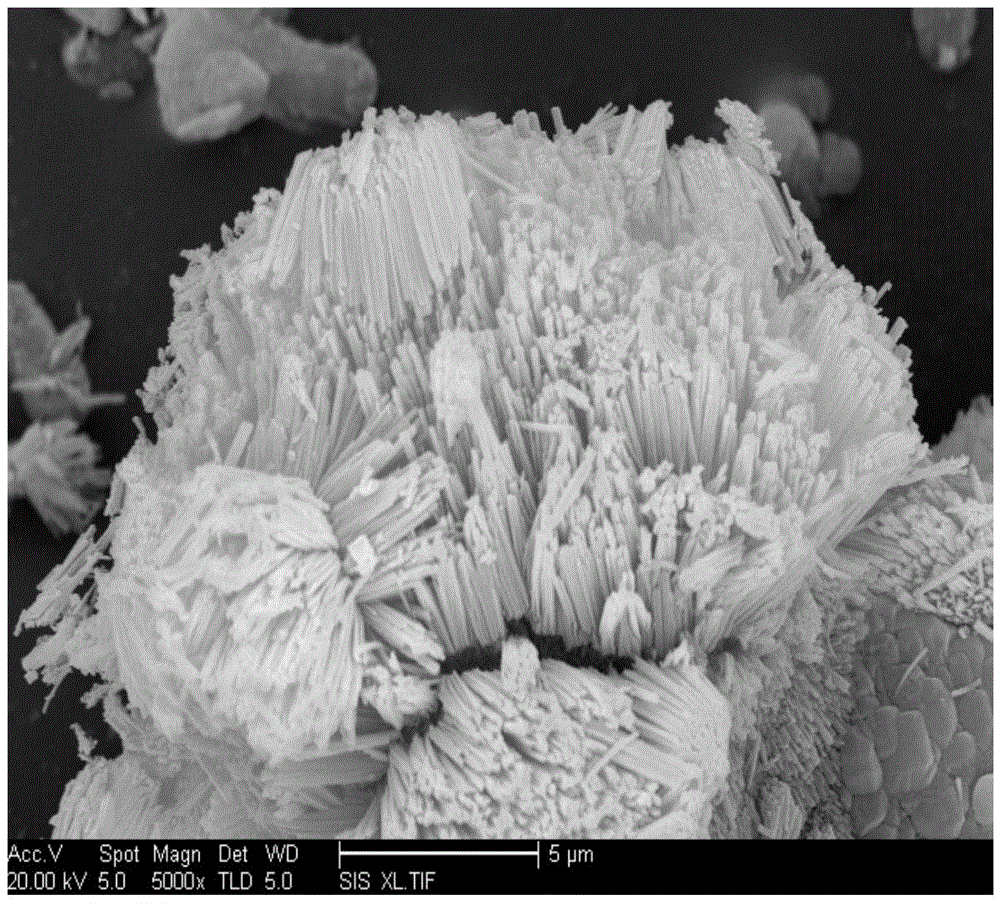

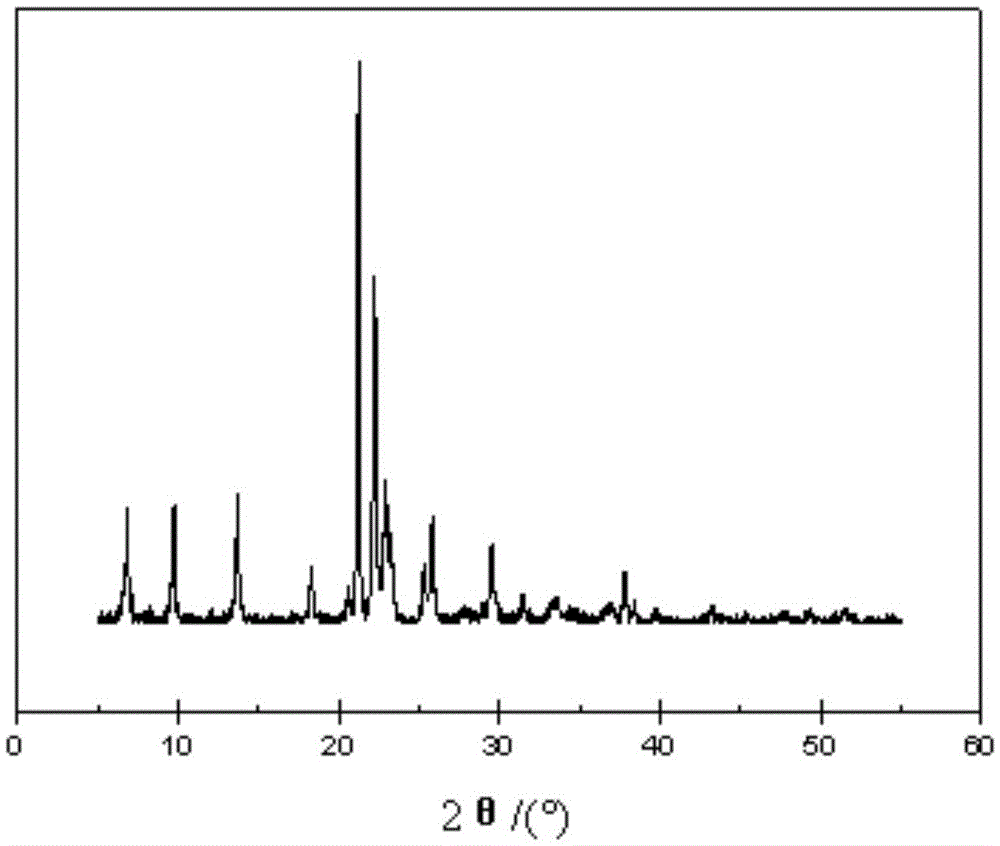

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: a kind of method for synthesizing CoAPO-41 molecular sieve described in this embodiment is specifically carried out according to the following steps:

[0024] 1. Preparation of initial gel: Weigh 85% phosphoric acid, secondary deionized water, pseudoboehmite, di-n-butylamine and cobalt nitrate by weighing 85% phosphoric acid Mix evenly with secondary deionized water to obtain a reaction system. Under the stirring condition of a rotating speed of 800r / min~1000r / min, add pseudo-boehmite, di-n-butylamine and cobalt nitrate to the reaction system in sequence, and stir for 20min ~40min to get the initial gel;

[0025] The mass ratio of 85% phosphoric acid to secondary deionized water is 1:(3.5~4.5); the mass percentage is the mass of 85% phosphoric acid and pseudo-boehmite The ratio is 1:(0.5~0.7); the mass ratio of phosphoric acid and di-n-butylamine in the described mass percentage is 1:(1.5~2.0); the described mass percentage is 85% The mass rat...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is: Al in the pseudo-boehmite described in step one 2 o 3 The mass percent composition of cobalt nitrate described in step one is 71.3%; The mass percent composition of cobalt nitrate described in step one is 99%; The mass percent composition of di-n-butylamine described in step one is 99%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: in step 2, the crystallization is carried out at a temperature of 170° C. to 190° C. for 12 hours to 24 hours. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com