Archimedes double-spiral division type hydraulic ejector

A hydraulic ejector and double-helix technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., to achieve pressure balance, solve failure problems, and achieve obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

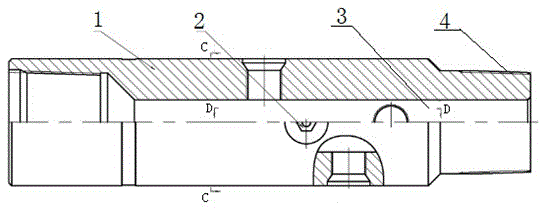

[0019] Such as figure 1 As shown in the schematic diagram of the Archimedes double-helix split-flow hydraulic injector, it includes the injector body 1 and the nozzle 2. It is characterized in that: the inner wall of the injector cavity 3 in the injector body 1 is distributed with two groups of Archimedes The flow passages 5 distributed in double helix lines, the nozzles 2 are arranged on two groups of flow passages 5 and connected to the outer surface of the injector body 1 .

[0020] The injector body 1 of the Archimedes double-helix split-flow hydraulic injector has a length of 370mm, an outer diameter of 100mm, and an inner diameter of 32mm. The pitch is 120mm, and the pitch of the double helix is 30mm.

[0021] In this hydro-ejector, the flow channel 5 with Archimedes double-helix distribution is designed on the inner cavity structure of the conventional hydro-ejector, and the parameters of the double-helix structure are optimized. On the flow channel 5, the sand-carr...

Embodiment 2

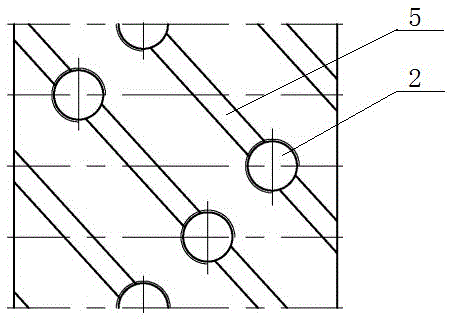

[0030] In this embodiment, two nozzles 2 are arranged on each of the two groups of flow channels 5 . Such as figure 2 As shown, the four nozzles 2 are evenly arranged on the flow channel 5 distributed in the Archimedes double helix, which can ensure that the sand-carrying fluid flows to each nozzle 2 along the double helix flow channel 5 in the injector inner cavity 3 middle.

[0031] The outlet of the nozzle 2 is also provided with a cover plate, which is threadedly connected to the injector body 1, so as to facilitate replacement when the nozzle is damaged. The structure of the cover plate belongs to common knowledge in the art, and will not be described in detail here.

[0032] The upper and lower ends of the injector body 1 are provided with threaded threads 4, the threaded threaded 4 is 2-7 / 8"NU, 10 teeth per inch, and the taper is 1:16. Through the thread and other equipment connection for easy disassembly, replacement and maintenance.

Embodiment 3

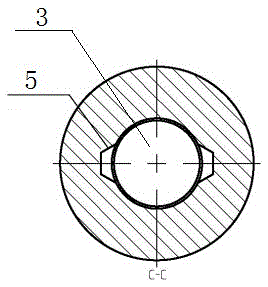

[0034] In this embodiment, the three-dimensional shape of the two groups of runners 5 distributed in the inner wall of the inner chamber 3 of the injector in the form of Archimedes double helix is a trapezoidal groove, see image 3 , wherein the groove length of the runner 5 trapezoidal groove is 120 mm, the groove depth is 5 mm, the width of the bottom of the groove is 10 mm, and the trapezoidal angle is 60°.

[0035] The injector body 1 is made of 35CrMo material, heat-treated HBW197~235, the inner cavity of the injector 3 is specially processed with the Archimedes double-helix trapezoidal structure flow channel 5, and the surface of the flow channel 5 of the double-helix trapezoidal groove is plated with nickel-based alloy material to prevent the local erosion of the spiral trapezoidal groove caused by the change of the direction of rotation (spin angle) of the fluid, and improve the effect of double helix swirl flow diversion; the nozzle 2 is made of erosion-resistant har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com