Intelligent anti-explosion liquid gas storage tank

A liquefied gas tank and intelligent technology, applied in the field of intelligent explosion-proof liquefied gas tank, can solve the problems of affecting personal safety, simple structure of the liquefied gas tank, many fire and safety hazards, etc., and achieve the effects of convenient production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

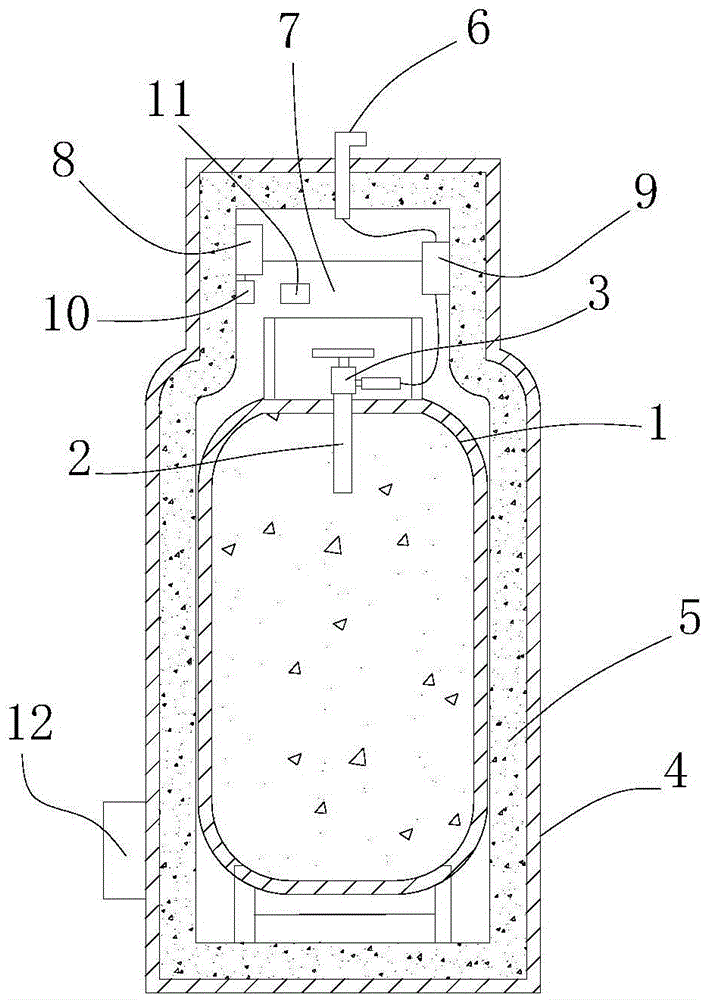

[0022] Embodiment 1: refer to figure 1 . An intelligent explosion-proof liquefied gas tank, comprising a gas storage tank 1 and an explosion-proof isolation tank or box 4, the top of the gas storage tank 1 is provided with a pipeline 2 communicating with the inside of the gas storage tank 1, and the top of the gas storage tank 1 is provided with a manual The gate valve 3 and the manual gate valve 3 are connected to the upper end of the pipeline 2. The gas storage tank 1 is arranged in an explosion-proof isolation tank or box 4, and a heat insulation layer 5 is arranged between the outer wall of the gas storage tank 1 and the inner wall of the explosion-proof isolation tank or box 4. The top of the explosion-proof isolation tank or box 4 is provided with an outlet pipe interface 6, and an installation cavity 7 is provided between the top of the gas storage tank 1 and the explosion-proof isolation tank or box 4, and the installation cavity 7 is provided with a controller 8, a ti...

Embodiment 2

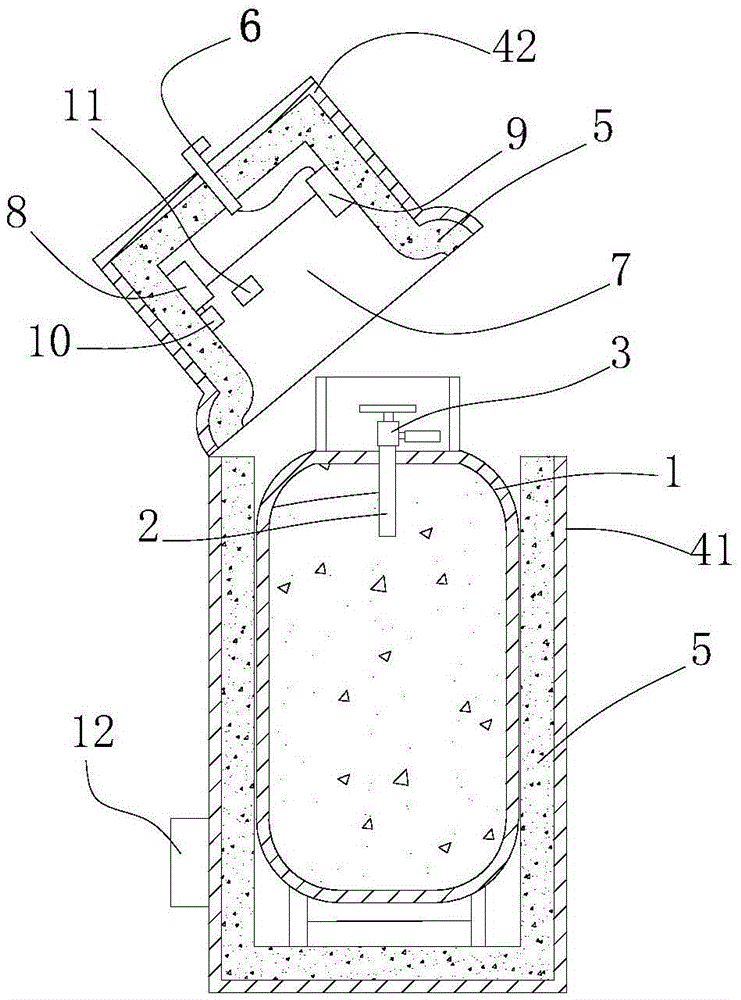

[0023] Embodiment 2, with reference to figure 2 , on the basis of Embodiment 1, the explosion-proof isolation tank or box 4 includes a main body 41 and a cover 42, the gas storage tank 1 is placed in the main body 41, and the cover 42 is set on the opening at the upper end of the main body 41. The heat insulation The layer 5 is provided on the inner walls of the main body 41 and the cover 42 around the gas tank 1 . The inner cavity of the cover 42 serves as the installation cavity 7 . The tank body at the lower end of the gas storage tank 1 is placed in the main body 41 , and its upper end is placed in the installation cavity 7 of the cover 42 .

Embodiment

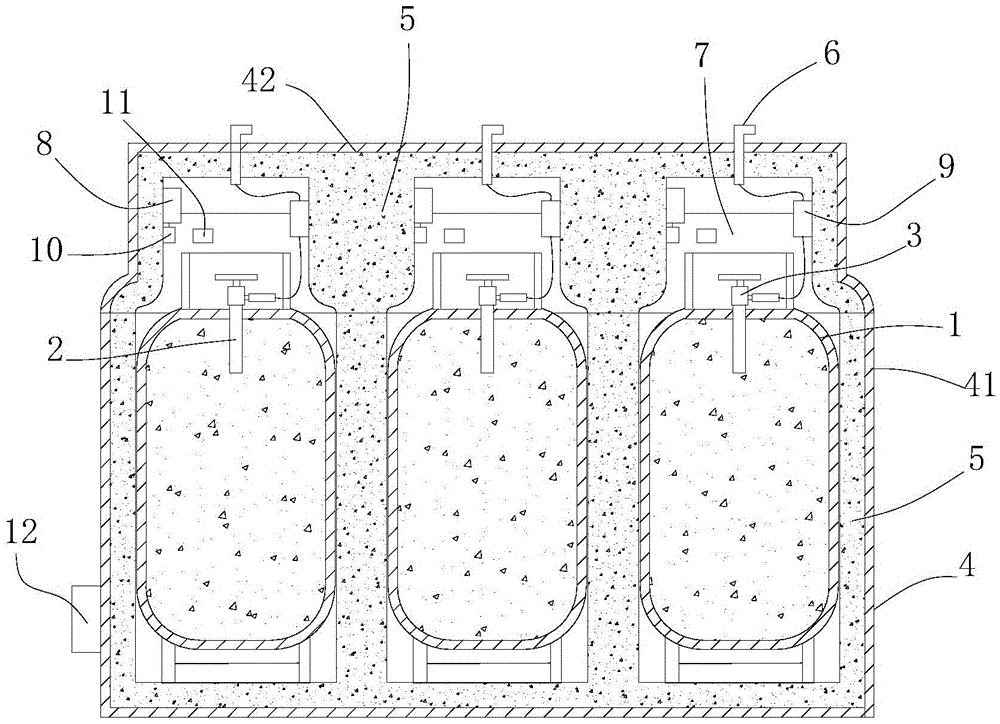

[0024] Example 3: Refer to image 3 . On the basis of Embodiment 1 or 2, the explosion-proof isolation tank or box 4 is a cabinet type, and at least one gas storage tank 1 can be placed therein, and the side of the gas storage tank 1 is connected to the cabinet type explosion-proof isolation tank or box 4 A thermal insulation layer 5 is arranged between the inner walls of the inner walls.

[0025] In addition, the design of this product is not only suitable for small household liquefied gas tanks, but also suitable for large liquefied gas tanks and various dangerous goods liquid tanks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com