Electrochromic device for screening solid inorganic electrochromic materials at high throughput and manufacturing method of electrochromic device

A technology of electrochromic devices and electrochromic materials, applied in instruments, nonlinear optics, optics, etc., can solve the problems of cumbersome operation, high technical difficulty, large error, etc., and achieve improved work efficiency, simple operation, and small error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

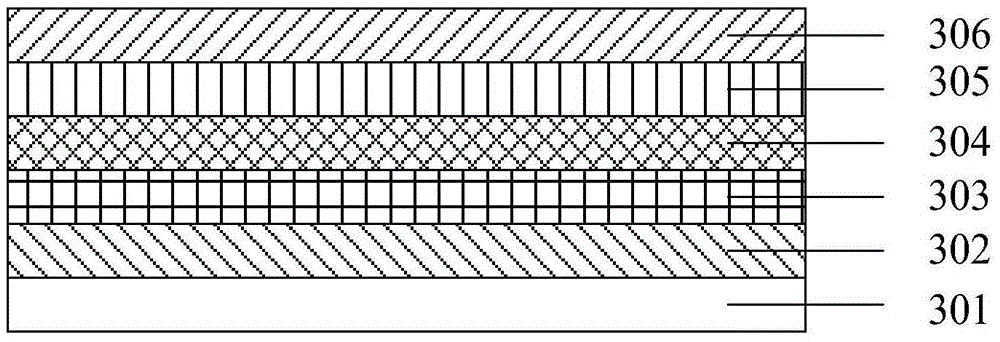

[0041] The glass substrate 301 that surface is deposited with indium oxide tin-doped thin film (lower transparent conductive layer 302) is fixed on the sample holder in the vacuum chamber of magnetron sputtering instrument; Wherein, the glass substrate 301 that surface is deposited with indium oxide tin-doped thin film It can be purchased externally, or the indium oxide tin-doped target can be selected to be plated on the surface of the glass substrate 301 by magnetron sputtering. In this embodiment, it is purchased directly for the convenience of the experiment; first substrate;

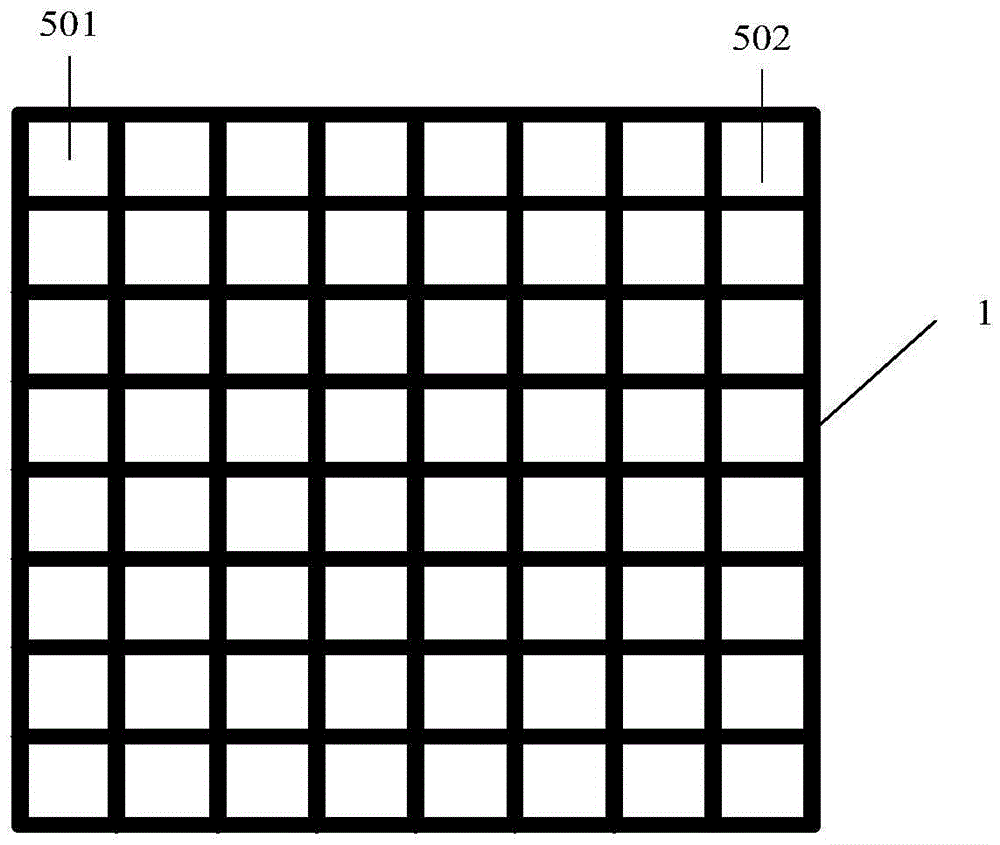

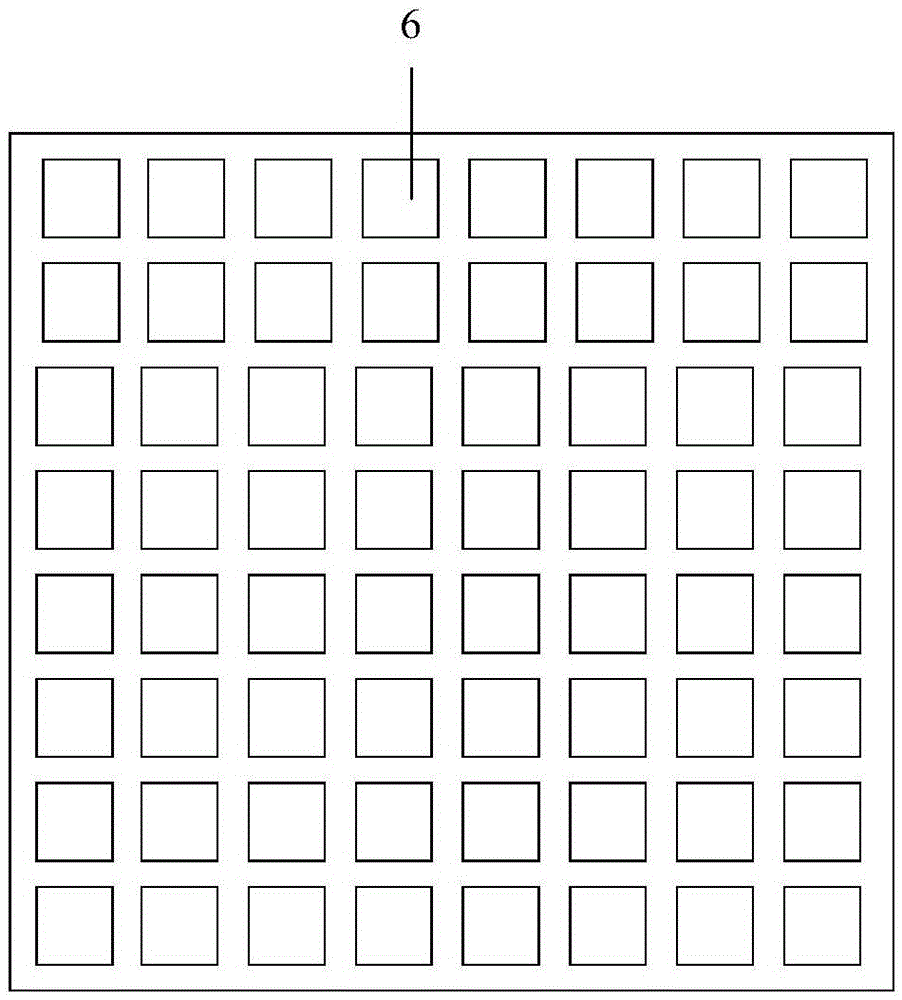

[0042] A polyimide tape is selected as the mask 1. The mask 1 has hollow cells arranged in a matrix of eight rows and eight rows. Each cell is separated by a non-conductive mask 1 and a distance of 2mm is generated. The length and width of each hollowed-out unit cell are 5×5mm, and the above-mentioned mask 1 is covered on the surface of the above-mentioned first substrate, the size of the mask 1 is ...

Embodiment 2

[0058] The glass substrate whose surface is deposited with indium oxide tin-doped film (lower transparent conductive layer) is fixed on the sample holder in the vacuum chamber of the magnetron sputtering instrument; wherein, the glass substrate whose surface is deposited with indium oxide tin-doped film can be directly external You can also choose an indium oxide-doped tin target, and use magnetron sputtering to plate it on the surface of the glass substrate. In this embodiment, it is directly purchased for the convenience of the experiment; the glass substrate with the indium oxide-doped tin film on the surface is used as the first substrate ;

[0059] A polyimide tape is selected as the mask 1. The mask 1 has hollowed-out cells arranged in a matrix of six rows and six rows. Each cell is separated by a non-conductive mask 1 and has a distance of 3mm. The length and width of each hollowed-out unit cell are 1×1mm, and the above-mentioned mask 1 is covered on the surface of the ...

Embodiment 3

[0075] The glass substrate whose surface is deposited with indium oxide tin-doped thin film (lower transparent conductive layer) is fixed on the sample holder in the vacuum chamber of magnetron sputtering instrument; Wherein, the glass substrate with surface deposited with indium oxide tin-doped thin film can be directly outside You can also choose indium oxide-doped tin target material, and use magnetron sputtering to plate on the surface of the glass substrate. In this embodiment, for the convenience of the experiment, the glass substrate with the indium oxide-doped tin film on the surface is used as the first substrate ;

[0076] A polyimide tape is selected as the mask 1, the mask 1 has hollow cells arranged in a matrix of three rows and five rows, and each cell is separated by a non-conductive mask 1 with a distance of 3 mm. The length and width of each hollowed-out cell are 2×2mm, and the above-mentioned mask 1 is covered on the surface of the above-mentioned first substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com