Preparation method of flexible battery

A flexible battery, flexible electricity technology, applied in secondary battery manufacturing, batteries, circuits, etc., can solve the problems of increasing the number of batteries in series and parallel, no advantages, flexibility and freedom restrictions, etc., to increase the capacity or The effect of output voltage, reducing the number of packaging, and improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

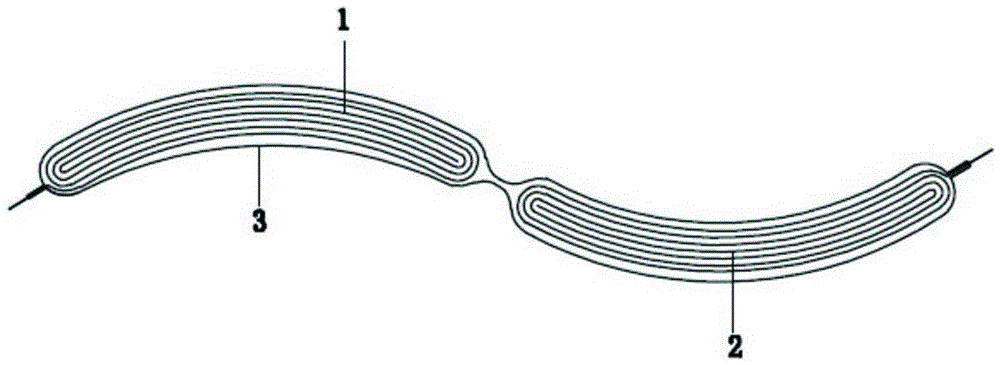

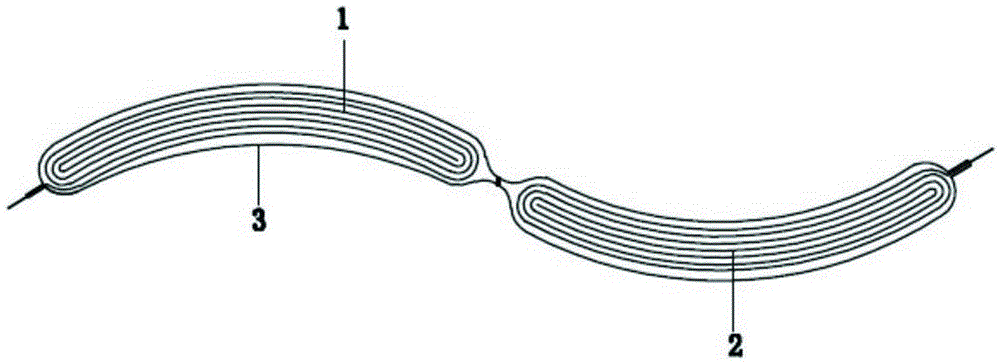

[0029] like figure 1 As shown, two electrically connected flexible battery units 1 and 2 are prepared, and the flexible battery units 1 and 2 are wound from positive pole pieces, negative pole pieces and a separator between them, and are coated with an insulating layer. It is insulated, and the positive and negative conductive terminals made of metal aluminum are shared between the two flexible battery units 1 and 2; the two flexible battery units 1 and 2 are connected in series and wrapped in a flexible packaging bag 3 Inside, a gap of 5 mm is reserved between the two flexible battery units 1 and 2, and the side and top edges of the flexible packaging bag 3 are heat-sealed; since the above two flexible battery units 1 and 2 can use the same electrolyte, so there is no need to separate the two flexible cell units 1 and 2 by heat sealing, and the electrolyte is directly injected into the flexible packaging bag 3, so that an electrolytic cell containing the electrolyte is formed...

Embodiment 2

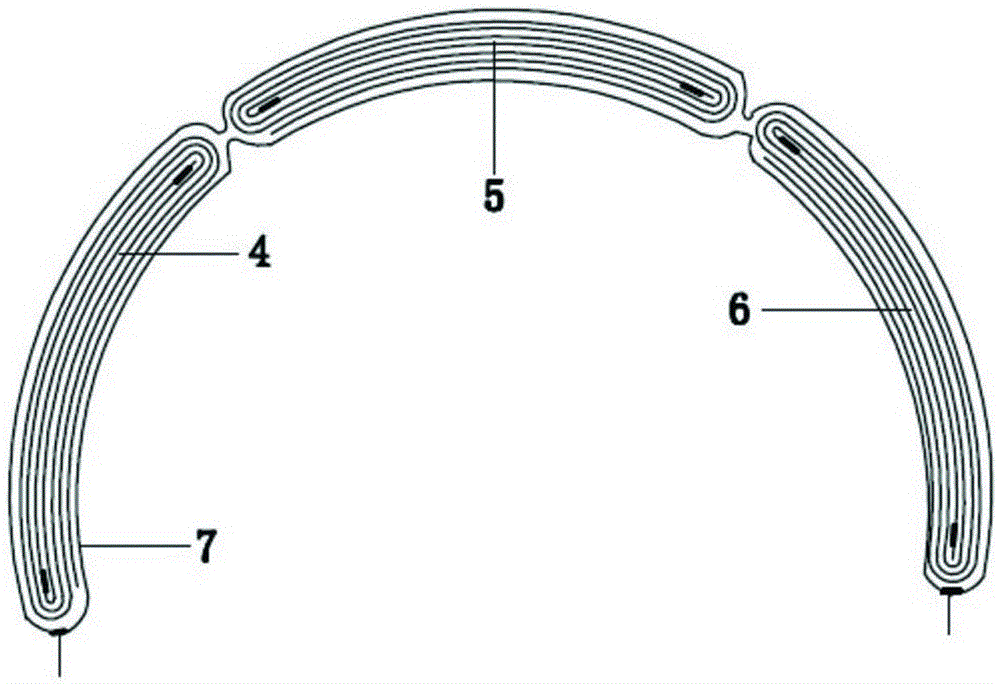

[0031] like figure 2 As shown, three electrically connected flexible battery units 4, 5, 6 are prepared, and the flexible battery units 4, 5, 6 are wound from positive pole pieces, negative pole pieces and a separator between them, and passed through Apply insulating glue to insulate it, and share the positive and negative conductive terminals made of metal nickel between the three flexible battery units 4, 5, and 6; connect the three flexible battery units 4, 5, and 6 in series The form connection is wrapped in the flexible packaging bag 7, and a gap of 2 mm is reserved between the three flexible battery units 4, 5, 6, and the side and the top edge of the flexible packaging bag 7 are heat-sealed; The cell units 4, 5, and 6 can use the same electrolyte, so there is no need to separate the two flexible cell units 4, 5, and 6 by heat sealing, and the electrolyte is directly injected into the flexible packaging bag 7, and then the flexible packaging The other side of the bag 7 ...

Embodiment 3

[0033] like image 3 As shown, the difference from Example 1 is that the flexible battery units 1 and 2 use different electrolytes, and heat-package is performed in the gap reserved between the flexible battery units 1 and 2, so that the flexible packaging bag 3 is formed Two electrolytic cells containing electrolytes are injected with different electrolytes into the two electrolytic cells, and then the other side of the flexible packaging bag 3 is sealed; the battery is formed, and the gas generated by the formation is collected in the flexible packaging bag 3, then puncture the airbag bag to release the gas generated by chemical formation, cut off the airbag bag and the redundant side, and finally obtain a flexible battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com