Cable bridge applicable for compressor set

A technology for cable trays and compressor units, which is applied to electrical components and other directions, can solve problems such as electrical circuit laying, and achieve the effect of regular space arrangement, compact structure and saving base space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

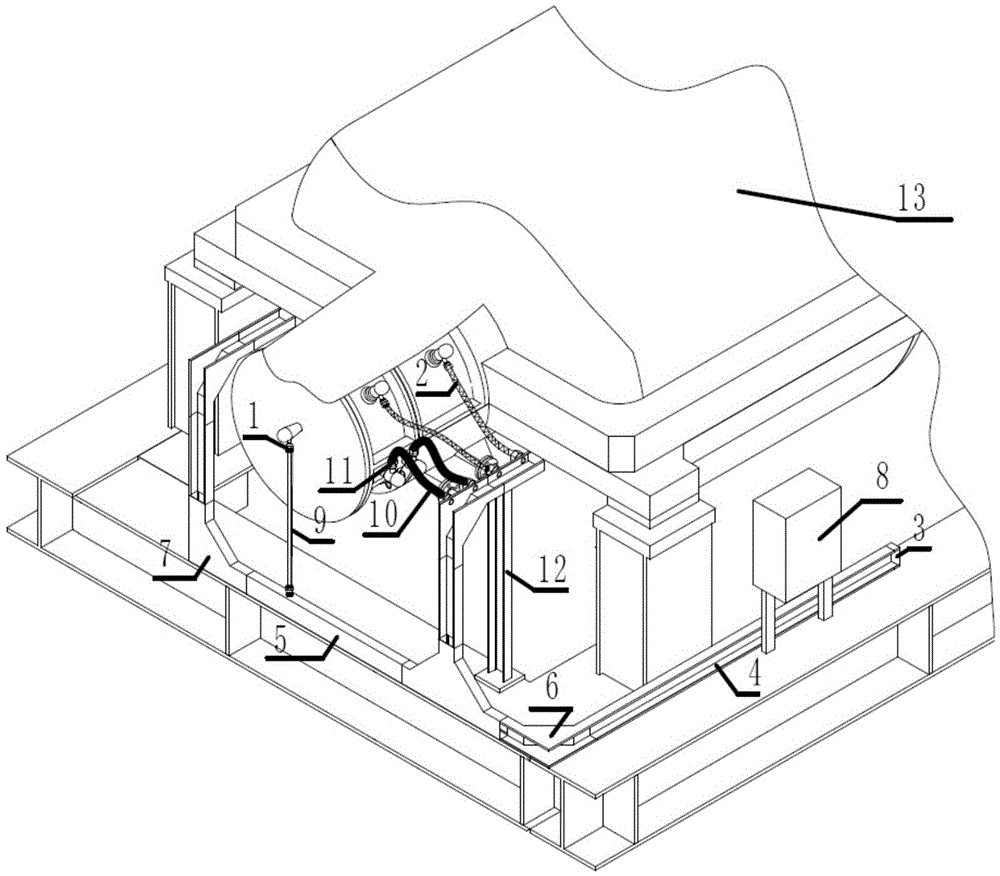

[0021] Cut the steel plates, splice and weld them into the following parts according to the following dimensions, the steel pipe size is 3 / 4 inch; the pipe joint (inner) is G3 / 4 inch; the cable bridge groove is 100 mm wide and 50 mm high; the horizontal bend connects its two right angles The length of the side is 350 millimeters and 350 millimeters; the length of its two right angles is 300 millimeters and 300 millimeters; the width of the cover plate is 100 millimeters. Finally, the bracket is welded and fixed on the base of the compressor unit to make a cable bridge.

[0022] Install the instrument on the compressor unit body or the base pipeline, and lead the cables to the bridge frame through the cable clamp sealing joint on the instrument, so that the cables are arranged in the bridge groove smoothly and beautifully, and the inside of the bridge frame can be led to the junction box terminal through the sealing joint On, hanger brackets (or pillars) for cable fixing. Afte...

Embodiment 2

[0024] Cut the steel plates, splice and weld them into the following parts according to the following dimensions, the steel pipe size is 3 / 4 inch; the pipe joint (inside) is G3 / 4 inch; the cable bridge groove is 100 mm wide and 80 mm high; the horizontal bend passes through its two right angles The length of the side is 300 mm and 250 mm; the length of its two right-angled sides is 350 mm and 300 mm; the width of the cover plate is 100 mm. Finally, the bracket is welded and fixed on the base of the compressor unit to make a cable bridge.

[0025] After installing the instrument on the compressor unit body or the pipeline on the base, the cables are led out through the terminal inside the instrument through the electrical interface of each instrument, connected to the bridge through the pipe joint through the steel pipe, and arranged in the bridge groove in a flat and beautiful way. The inside of the bridge can be passed Coupon bracket (or post) for cable fixing. After the cab...

Embodiment 3

[0027] Its structure and size are the same as embodiment 1, but it is horizontally fixed on the base of the compressor unit with the shoulder by the nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com