Printed circuit board

A technology of printed circuit boards and contact circuits, which is applied in the direction of printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problems of slow production and processing speed, inconvenient maintenance and disassembly, and multiple PCB wiring areas, so as to reduce production costs , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

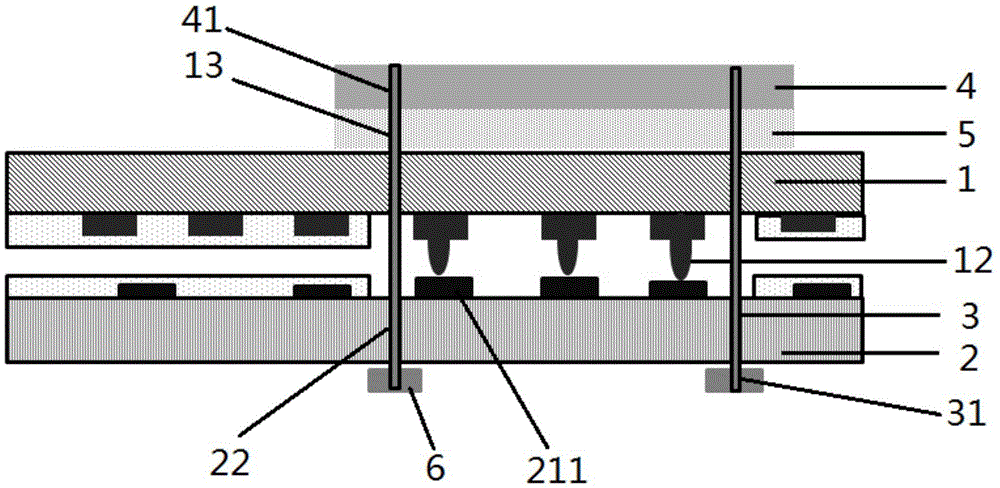

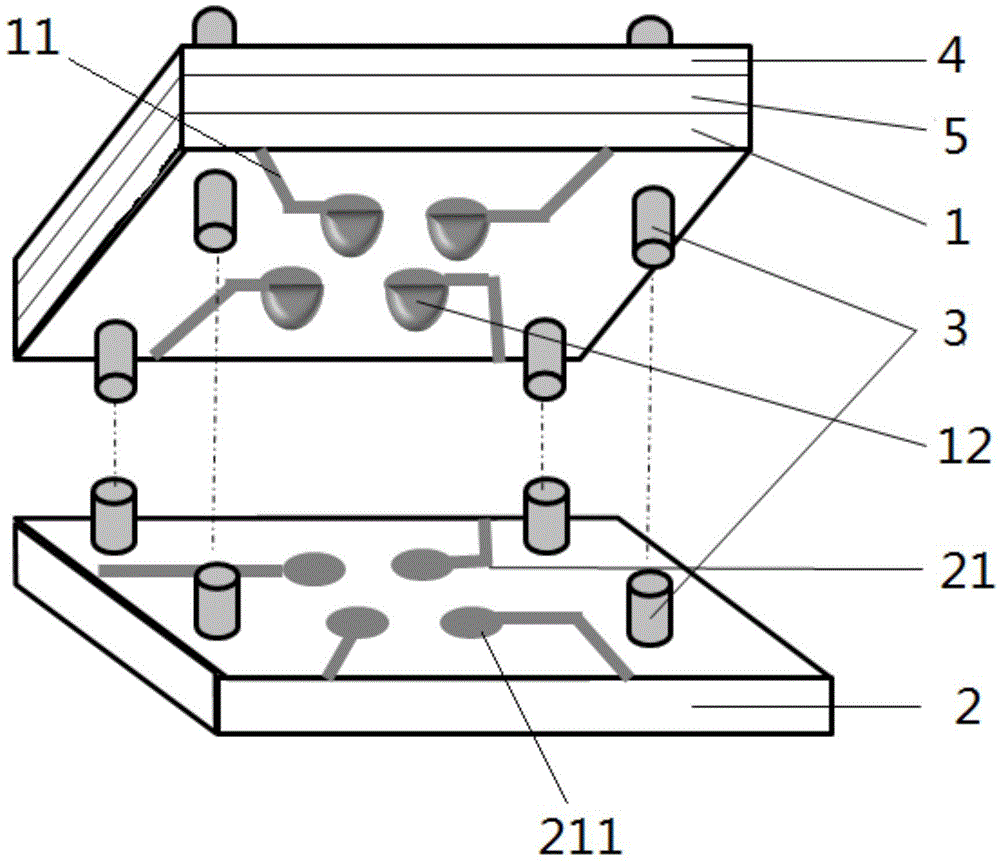

[0026] This embodiment discloses a printed circuit board, refer to Figure 1~2 , including an FPC daughter board 1 and a PCB mother board 2, the FPC daughter board 1 is installed on the PCB mother board 2, the FPC daughter board 1 is provided with a conductive convex hull 12, and the PCB motherboard 2 is provided with a conductive convex hull 12 Corresponding to the contact circuit 211 , the conductive protrusion 12 is in contact with the corresponding contact circuit 211 , so as to realize the circuit connection between the FPC sub-board 1 and the PCB motherboard 2 . For the printed circuit board disclosed in this embodiment, a more specific description is as follows:

[0027] like Figure 1~2 As shown, a first connection line 11 (including components) is laid on the FPC sub-board 1 , wherein the first connection line 11 is laid by a conventional process, and the components are laid by a conventional welding method. After the laying of the first connection line 11 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com