Mobile terminal

A technology for mobile terminals and heating elements, which is applied in cooling/ventilation/heating transformation, electrical components, and structural parts of electrical equipment. Automated operation, improved heat dissipation performance, and labor cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

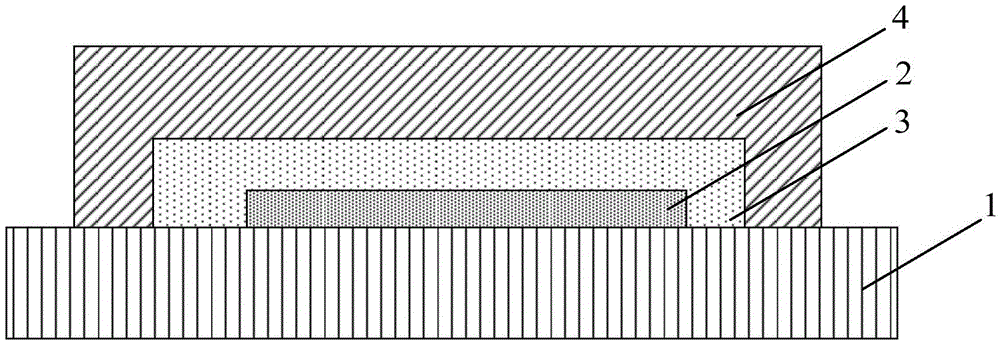

Embodiment 1

[0016] figure 1 It is a schematic structural diagram of the heat dissipation part in the mobile terminal provided by Embodiment 1 of the present invention. The heat conduction gap around the heating element in the mobile terminal can be effectively filled with heat conduction gel, which improves the heat generation performance of the heat generating element. Wherein, the mobile terminal may be a smart phone, a tablet computer, or a personal digital assistant. Such as figure 1 As shown, the mobile terminal includes a printed circuit board 1, a first heating element 2 arranged on the printed circuit board 1, and a first thermally conductive gel 3 covering the first heating element 2, the first thermally conductive gel 3 is used for filling The thermal conduction gap of the first heating element 2 .

[0017] Among them, the thermally conductive gel has the characteristics of high thermal conductivity, low thermal resistance, good conformability, insulation, can automatically f...

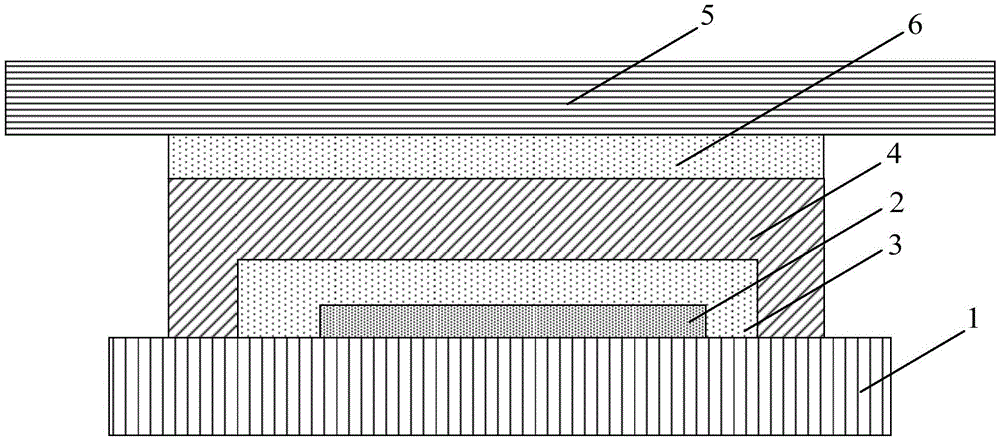

Embodiment 2

[0026] figure 2 It is a schematic structural diagram of the heat dissipation part in the mobile terminal provided by Embodiment 2 of the present invention. The difference between this embodiment and the first embodiment is that it further includes a middle frame disposed above the first shielding cover. Such as figure 2 As shown, the mobile terminal of this embodiment may include a printed circuit board 1, a first heating element 2 arranged on the printed circuit board 1, a first thermally conductive gel 3 covering the first heating element 2, and a first heating element 3 arranged on the first heating element 2. The first shielding cover 4 on the periphery of the element 2 and the middle frame 5 arranged above the first shielding cover 4 are used to diffuse the heat transmitted from the first heating element 2 to the middle frame 5, so as to prevent the front screen of the mobile terminal from absorbing More heat causes the screen temperature of the mobile terminal to be ...

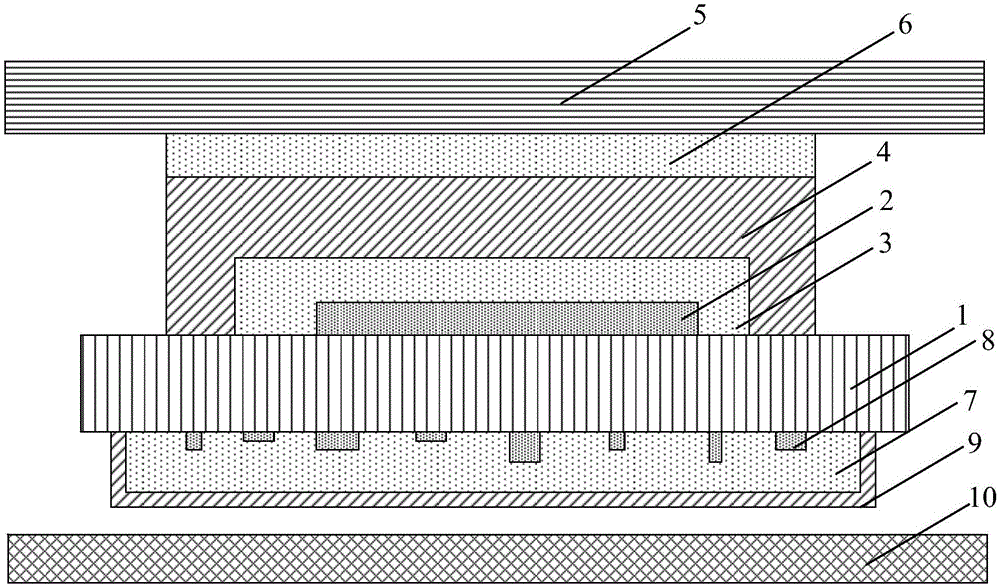

Embodiment 3

[0034] image 3 It is a schematic structural diagram of the heat dissipation part in the mobile terminal provided by the third embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that the first heating element is arranged on the first surface of the printed circuit board, and the second surface of the printed circuit board corresponds to the position of the first heating element with a third thermally conductive gel . Such as image 3 As shown, the mobile terminal of this embodiment may include a printed circuit board 1, a first heating element 2 arranged on the first surface of the printed circuit board 1, a first heat-conducting gel 3 covering the first heating element 2, and a The first shielding cover 4 on the periphery of the first heating element 2, the middle frame 5 arranged above the first shielding cover 4, and the third heat conduction gel glued to the second surface of the printed circuit board 1 corresponding to the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com