Method for manufacturing sponge titanium and zirconium electrode through explosion

A technology of sponge titanium and electrodes, applied in the field of zirconium electrodes and explosive production of sponge titanium, can solve the problems of low production efficiency, low electrode quality and inability to meet the requirements, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

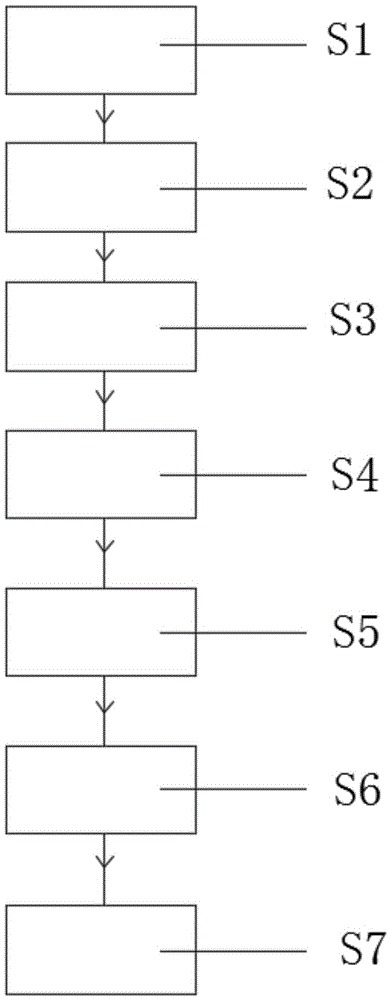

[0019] Such as figure 1 Shown the present invention provides a kind of explosion making method for sponge titanium, zirconium electrode, and it comprises the steps:

[0020] S1: Mixing: Put the heated raw materials (alloys) into the stirring device for stirring, so that the raw materials (alloys) are evenly mixed;

[0021] S2: Mold assembly: install the mold core into the lower mold, and ensure that the installation position of the mold core meets the requirements;

[0022] S3: charging: pour the raw material (alloy) mixed in the step S1 into the gap between the lower mold and the mold core in the step S2;

[0023] S4: mold closing: the upper mold is closed on the lower mold, so that the lower end of the upper mold extends into the gap between the lower mold and the mold core, and the top of the upper mold is connected with a lower platen;

[0024] S5: laying explosives: laying an appropriate amount of explosives on the upper plane of the lower platen in step S4;

[0025] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com