Preparation method of low-viscosity sodium carboxymethylcellulose

A technology of sodium carboxymethyl cellulose and low viscosity, applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of increasing the difficulty of product separation and purification, side reactions, disadvantages, etc., to avoid Effects of washing dissolution loss, short reaction cycle, and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

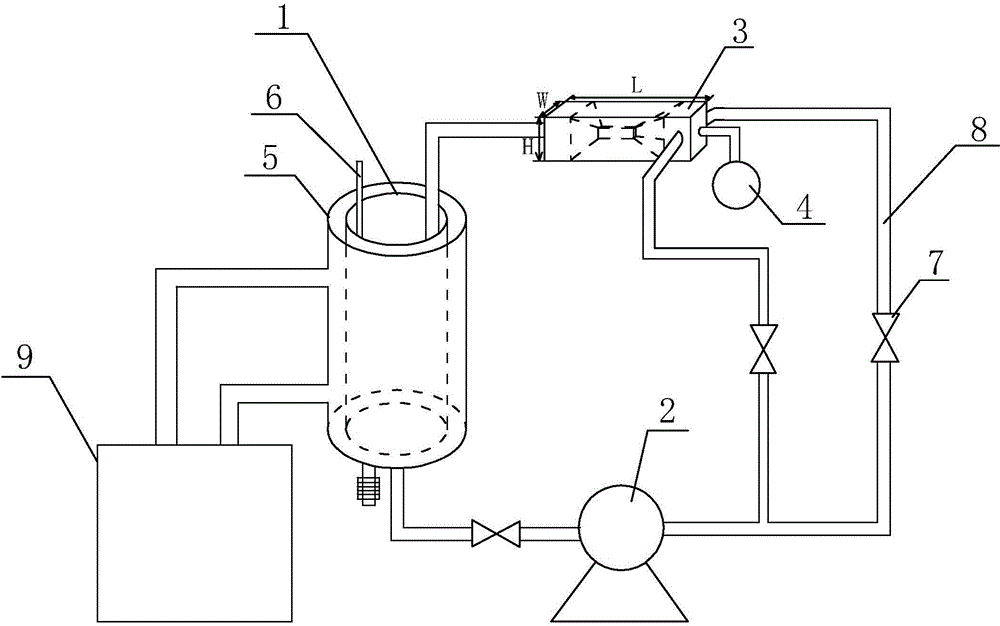

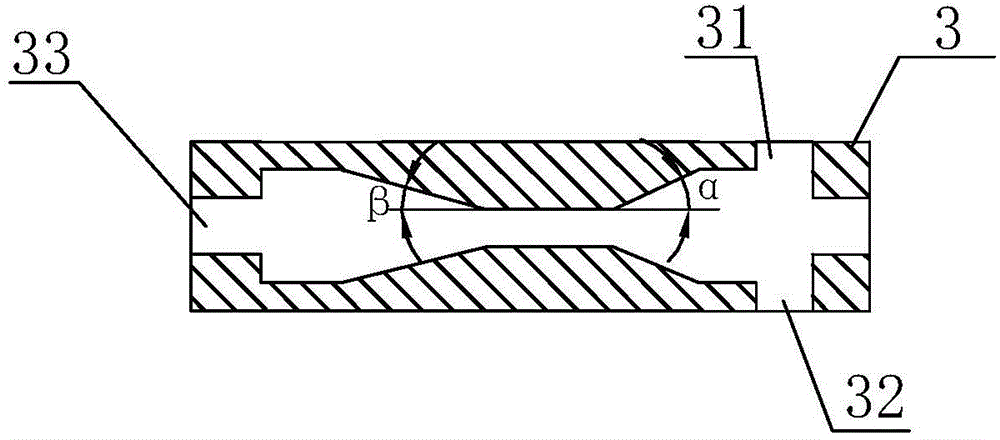

[0024] A preparation method of low-viscosity sodium carboxymethyl cellulose, comprising the steps of:

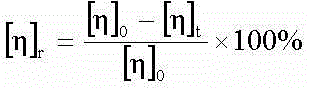

[0025] A. Solution preparation: Weigh 10.00g of carboxymethylcellulose sodium (CMC) solid powder, dry in a constant temperature drying oven at 105°C for 2 hours, and weigh 6.00g of dried carboxymethylcellulose sodium with an electronic balance Add the sodium carboxymethyl cellulose to distilled water with a constant temperature of 80°C while stirring, and stir on a constant temperature magnetic stirrer for one hour to completely dissolve the sodium carboxymethyl cellulose to obtain carboxymethyl cellulose with a concentration of 6g / L. Sodium methylcellulose solution, after the sodium carboxymethylcellulose solution is cooled, it is left to stand overnight to discharge the gas dissolved in the sodium carboxymethylcellulose solution, and then the sodium carboxymethylcellulose solution Diluted to a concentration of 3g / L sodium carboxymethyl cellulose solution, then adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com