Copper/graphene composite multi-layer heat dissipation film

A graphene composite and graphene layer technology, applied in cooling/ventilation/heating transformation, electrolytic inorganic material coating, modification through conduction heat transfer, etc., can solve the problems of limited heat dissipation direction and low heat dissipation efficiency of heat dissipation film, etc. Achieve the effect of improved heat dissipation efficiency and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will now be described in detail in conjunction with the accompanying drawings.

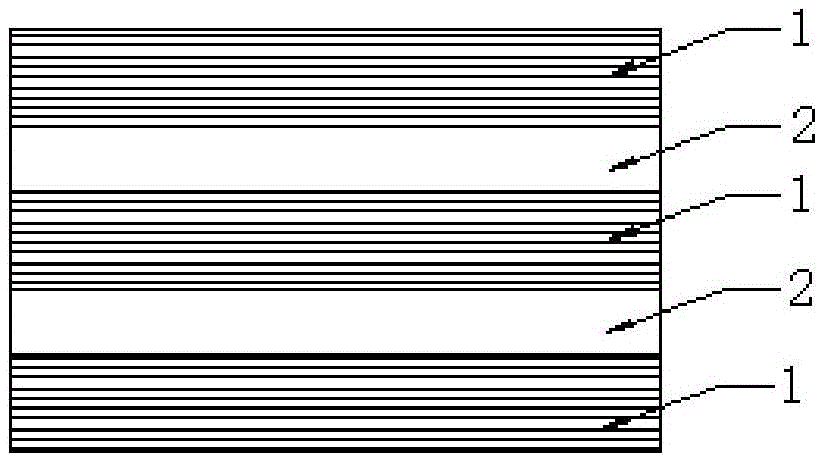

[0025] The copper / graphene composite multilayer heat dissipation film of the present invention is mainly composed of graphene layers 1 and copper layers 2 alternately stacked. Wherein, the number of layers of the graphene layer and the copper layer can be set according to the requirements of large-area industrial use of electronic equipment. In the present invention, the surface layer of the copper / graphene composite multilayer heat dissipation film is preferably a graphene layer , the middle layer is formed by alternately stacking copper layers and graphene layers, and its total thickness is 10-50 μm.

[0026] The preparation method of the copper / graphene composite multilayer heat dissipation film of the present invention mainly comprises the following steps: Step 1, take a piece of metal substrate, chemical degreasing; Step 2, deposit a lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com