Dust removal and drainage macroporous asphalt pavement with graded crushed stone composite layer

A technology for grading crushed stone and asphalt pavement, which is applied in the direction of pavement cleaning, on-site paved condensate pavement, roads, etc. It can solve the problems that dust and stone chips cannot be cleaned, damage the overall structure of the pavement, and weaken the anti-skid performance of the pavement, etc. problems, achieve the effect of restoring and maintaining drainage noise reduction and anti-skid ability, a wide range of uses, and reducing rutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

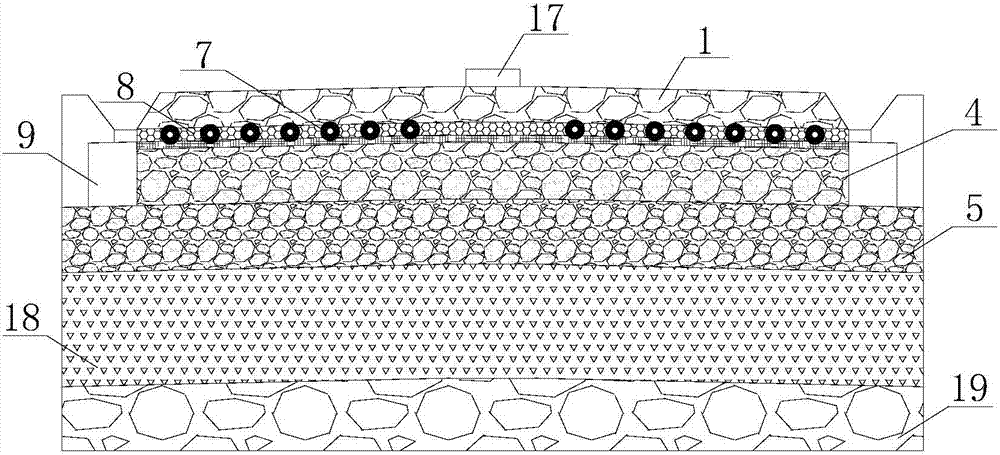

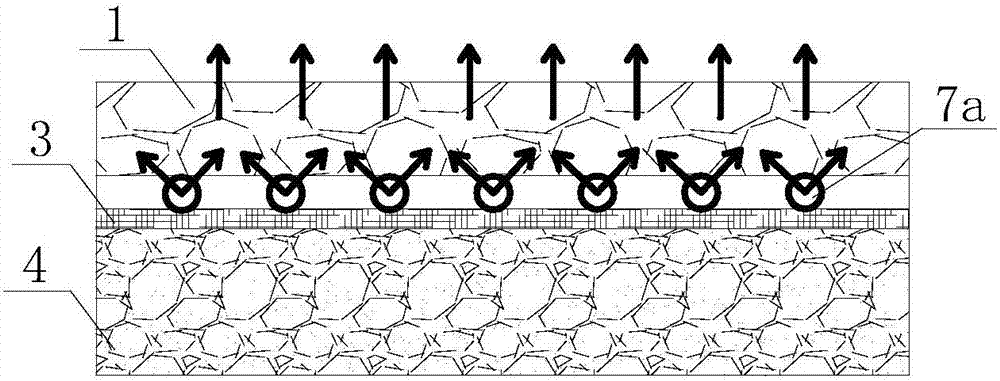

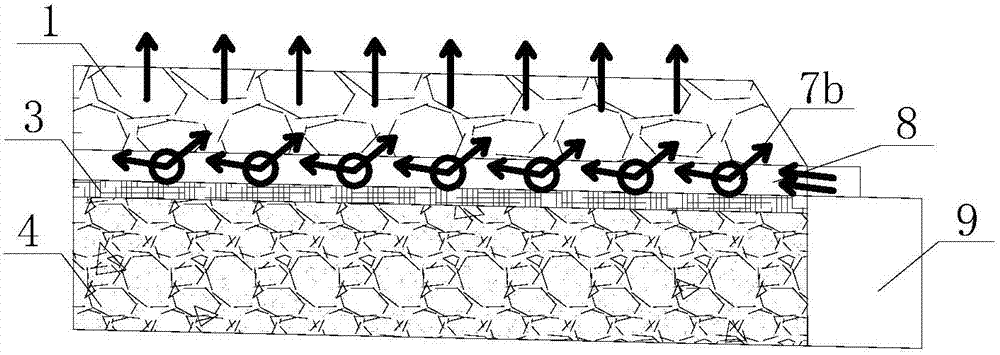

[0036] see figure 1 , the structural form of the dust-removing and drainage large-porosity asphalt pavement containing the graded crushed stone composite layer in this embodiment is: the pavement structure is set as the lower layer 5, the middle surface layer 4, the waterproof and crack-resistant layer 3, and the dust removal composite layer from bottom to top. layer and the upper layer 1, the waterproof and anti-crack layer can prevent the pavement water flow from penetrating into the middle surface layer and below, and the water flow flows to both sides of the road along the waterproof and anti-crack layer; Dust removal device 7; the dust removal device 7 is a dust removal pipeline arranged in a grid in the fixed layer of graded crushed stones 8, the dust removal device and the fixed layer of graded crushed stones are on the same plane, inhibiting each other, and improving the integrity of the dust removal composite layer , A through hole is opened on the pipe wall of the du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com