Side compressive cotton straw grass brick and manufacturing method thereof

A technology of cotton straw and its production method, which is applied in the field of building materials, can solve the problems of straw bricks increasing the difficulty of masonry, low side strength and unable to meet the performance requirements of non-load-bearing partition walls, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

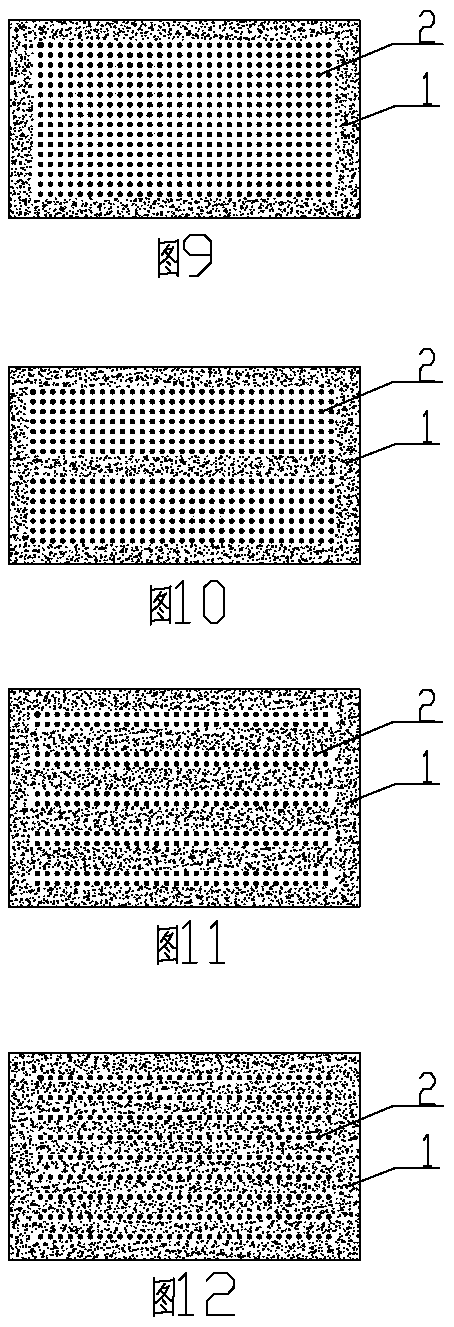

[0062] Example 1, the side compression cotton stalk grass brick raw material includes 1 to 3 parts of composite material 1 and 1 to 6 parts of cotton stalk 2 in parts by weight; wherein: the raw material of composite material 1 contains 30 to 3 parts by weight 40 parts of plaster, 5 to 20 parts of bentonite, 5 to 25 parts of clay, 1 to 5 parts of nylon fiber, 20 to 40 parts of slag, and 20 to 50 parts of water.

Embodiment 2

[0063] Example 2, the side compression cotton stalk grass brick raw material includes 1 or 3 parts of composite material 1, 1 or 6 parts of cotton stalk 2 in parts by weight; wherein: the raw material of composite material 1 contains 30 or 3 parts by weight 40 parts of plaster, 5 or 20 parts of bentonite, 5 or 25 parts of clay, 1 or 5 parts of nylon fiber, 20 or 40 parts of slag, 20 or 50 parts of water.

Embodiment 3

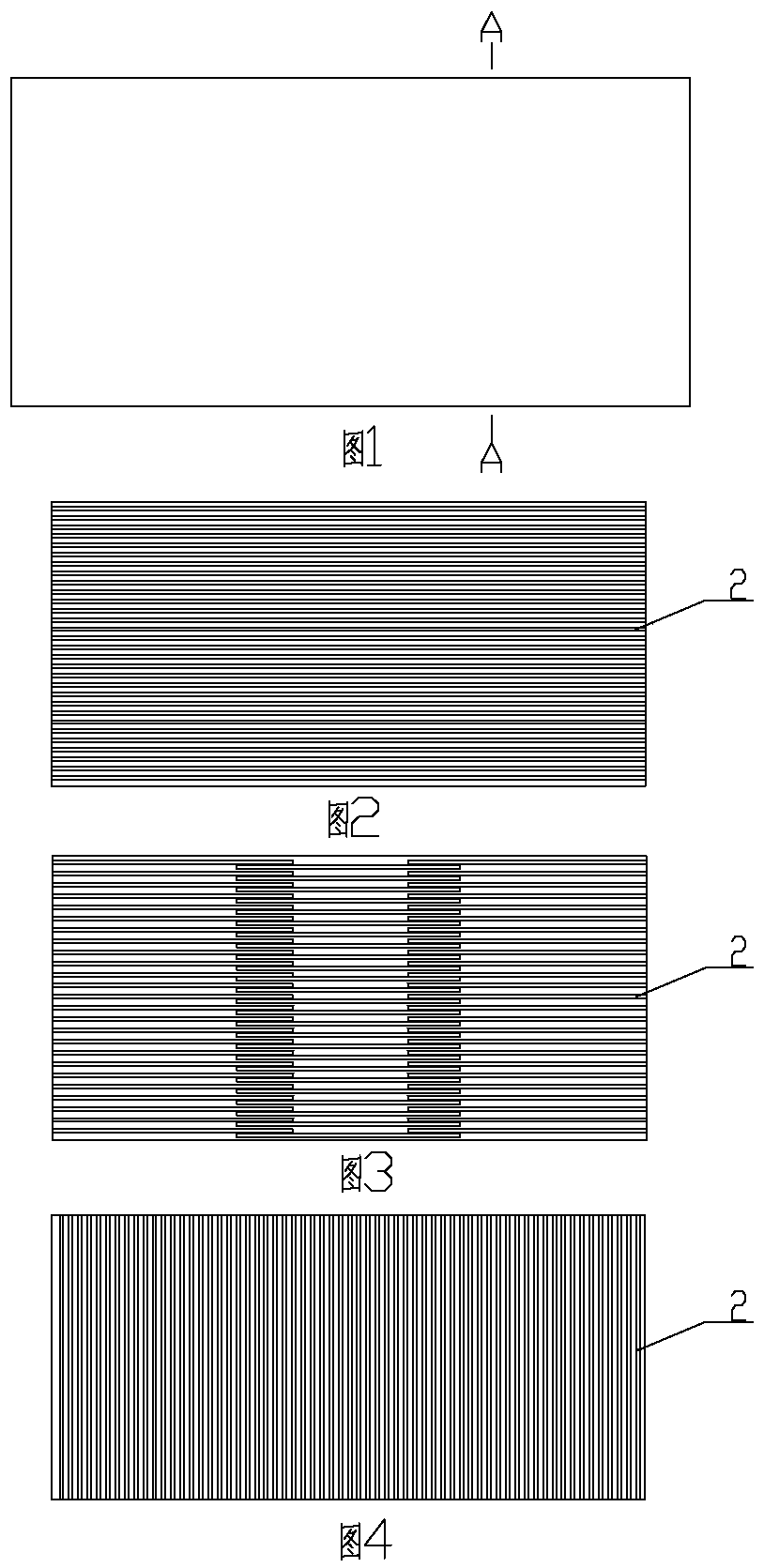

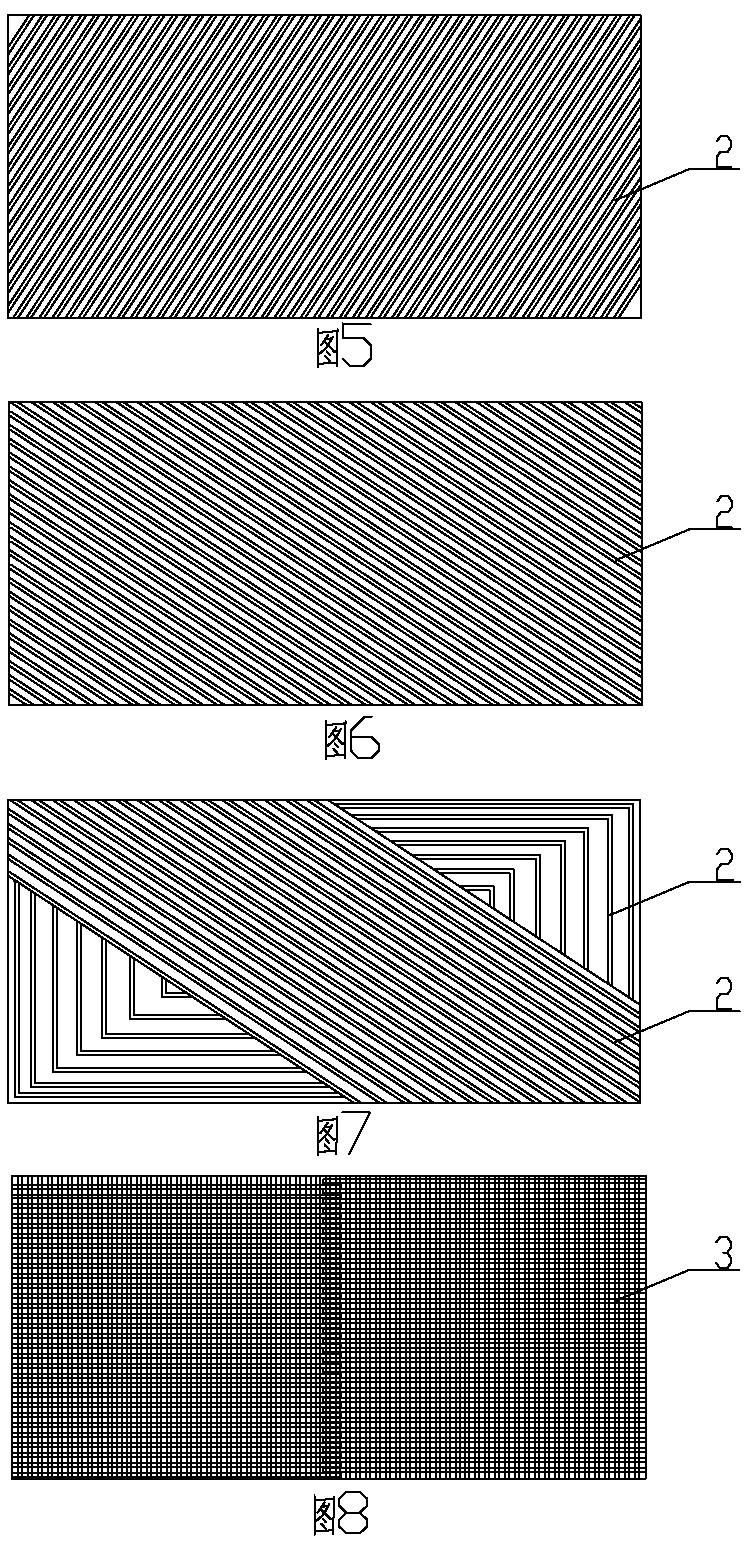

[0064] Embodiment 3, as shown in accompanying drawing 1, 2, 3, 4, 5, 6, 9, the manufacture method of this side pressure-resistant cotton straw grass brick is carried out according to the following steps: the first step, in the brick making mold Place the cotton stalks 2 horizontally or vertically or obliquely until the height of the brick-making mold; in the second step, use special machinery to press and form and fix two to six fastening wires at intervals, and insert a The two ends of the tensioning piece are tightened and fixedly connected with the corresponding fastening iron wires, and then a layer of composite material 1 is applied on the outside, and after standing for 24 hours, the side compression cotton straw grass brick is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com