Frozen-blockage-preventing oil well sampling device for oilfields

A sampling device and oil well technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve problems such as sampling difficulties, achieve convenient sampling and analysis, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

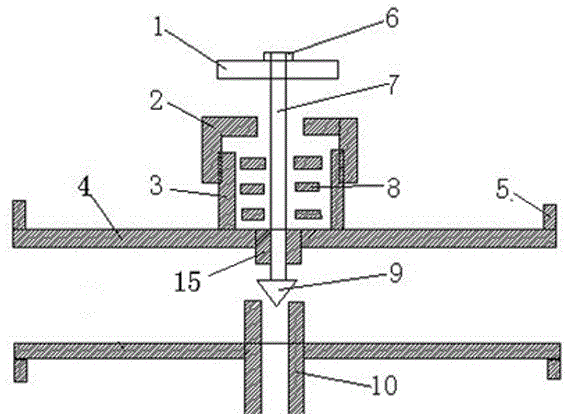

[0020] Oilfield of the present invention is used anti-freeze plugging oil well sampling device such as figure 1 , Figure 5 to Figure 8 As shown, it includes an oil pipeline 4 and a sampling port 10. The sampling port is connected to the lower part of the oil pipe through a thread 16. There is a fastening nut 17 on the sampling port, which is fastened with a fastening nut. The two ends of the oil pipeline are provided with clamps 5. Through The clamp is connected with the oil production pipeline. The sampling device is provided with an adjusting rod 7, a screw nut 15 and a sealing mechanism. The lead screw nut is inserted and welded at the position corresponding to the sampling port on the upper part of the oil pipeline. The sealing mechanism includes a sealing gland 2 and a sealing sleeve 3, the sealing sleeve is welded around the screw nut, the sealing sleeve is equipped with a sealing packing 8, the sealing packing is graphite packing, and the sealing gland and the sealin...

Embodiment 2

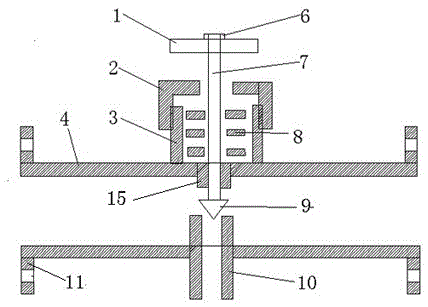

[0023] Another embodiment of the present invention is as figure 2 As shown, the two ends of the oil pipeline 4 are provided with flanges 11, the two ends of the oil pipeline are connected to the oil production pipeline through the flanges, and the sealing packing 8 in the sealing sleeve 3 is nylon packing. Others are the same as in Example 1.

Embodiment 3

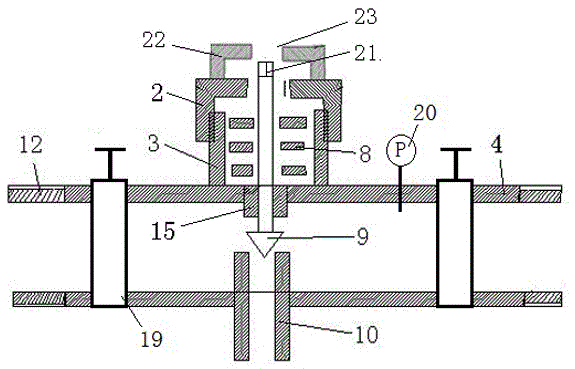

[0025] Another embodiment of the present invention is as image 3 As shown, the oil pipeline 4 is provided with a butterfly valve 19 and a pressure gauge 20, the butterfly valve is installed on both sides of the sampling port 10, the pressure gauge is located downstream of the sampling port, and is installed between the sampling port and the butterfly valve. The upper end of regulating rod 7 is provided with anti-theft nut 21, and anti-theft nut is a pentagonal or heptagonal structure for female, must special-purpose anti-theft wrench just can switch. Add a short tube 22 on the top of the sealing gland 2, the top of the short tube is provided with a cover with a central hole 23, the short tube covers the upper part of the adjusting rod with the anti-theft nut, the anti-theft wrench enters from the hole on the top, and the sampling device is checked. switch. The two ends of the oil pipeline 4 are provided with threaded fasteners 12, and the two ends of the oil pipeline are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com