Device and method for two-phase anaerobic fermentation methanogenesis from yellow corn silage straw

A technology for anaerobic fermentation and methane production, which is applied to special-purpose bioreactors/fermenters, fermentation, biochemical cleaning devices, etc., and can solve the problems of inability to dynamically control variables and sampling analysis, lack of experimental devices for methane production devices, etc. , to achieve the effect of convenient sampling analysis and convenient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

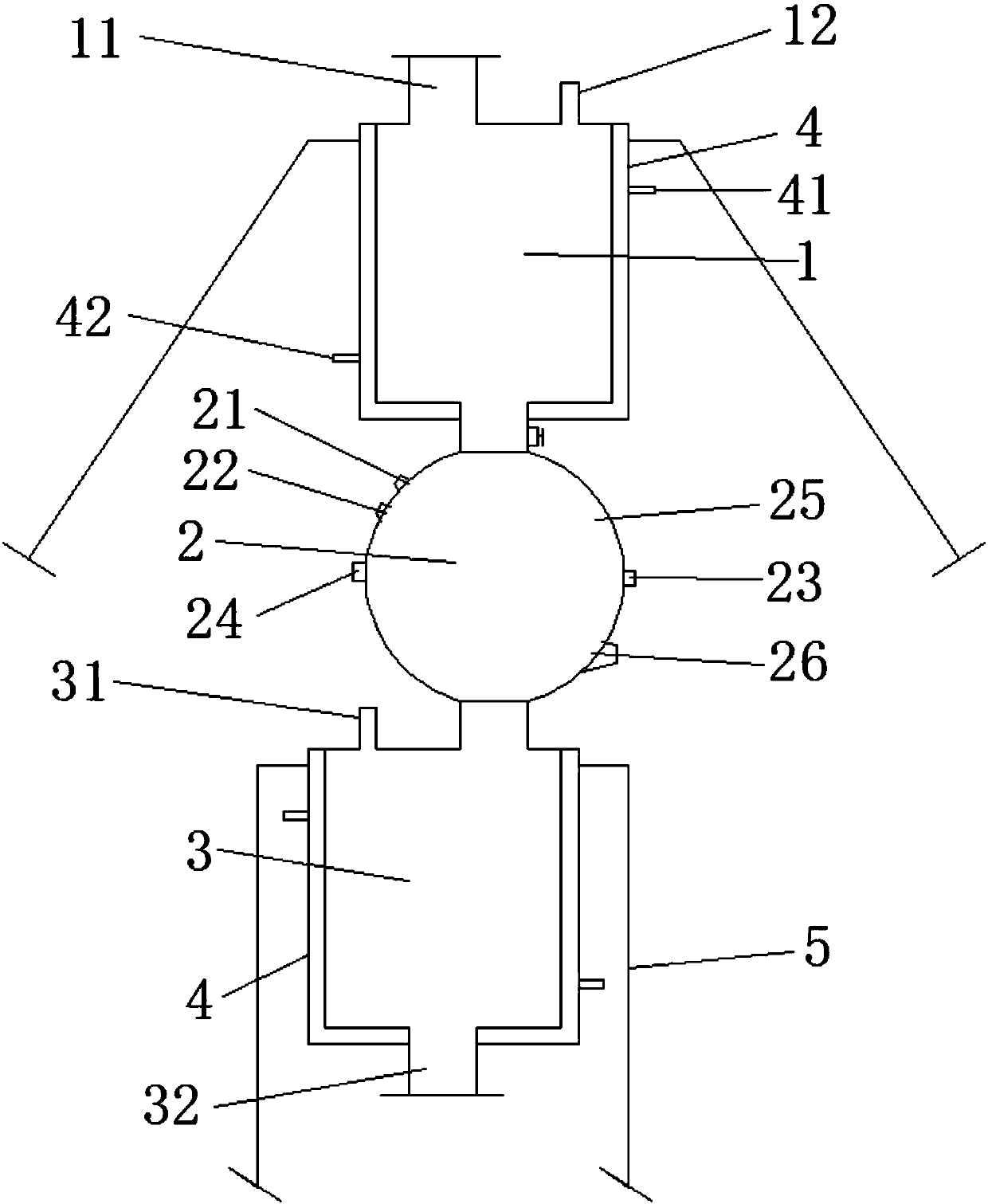

[0027] to combine figure 1 As shown, this embodiment discloses a two-phase anaerobic fermentation methane production device for yellow storage straw, using yellow storage straw as fermentation raw material, the device includes: acid production tank 1, premixing cabin 2 and methane production tank 3, The volumes of the acid generating tank 1 and the methane tank 3 are both 20L, the acid generating tank 1 is mainly used for producing acetic acid, and the methane tank 3 is mainly used for producing methane, and the lower end of the acid generating tank 1 is connected with the upper end of the premixing cabin 2, The lower end of the premixing cabin 2 is connected to the upper end of the methanation tank 3, the outer layers of the acid production tank 1 and the methanation tank 3 are provided with a water bath jacket 4, and the two sides of the water bath jacket 4 are oppositely provided with a water bath inlet 41 and a water bath outlet 42, and the water bath inlet 41 is set highe...

specific Embodiment approach 2

[0031] This embodiment is a method for two-phase anaerobic fermentation of yellow stalks to produce methane for continuous and stable fermentation experiments, including the following steps:

[0032] Step a: Divide the traditional two-phase anaerobic fermentation process of yellow storage straw into two parts, one part is used for the production of acetic acid, and the conditions for the realization of the caproic acid production phase: the oxidation-reduction potential Eh must be below +50mv; the pH is 4.5±0.2, PH decreases, propionic acid increases; microorganisms are mainly anaerobic, facultative acid-producing bacteria, and hydrolytic bacteria, and adopt normal temperature facultative anaerobic fermentation process, and the other part is used for methane production, and the methane production phase is realized Conditions: Strict anaerobic, methanogenic flora, pH control at 7±0.3, and anaerobic fermentation process at 55°C high temperature;

[0033] Step b: directly acidify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com