Packing seal structure

A packing seal and packing ring technology, which is applied to shaft seals, valve details, engine components, etc., can solve problems such as insufficient stability, poor sealing performance, and poor sealing performance of valves, so as to eliminate valve problems and improve utilization. , Strengthen the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

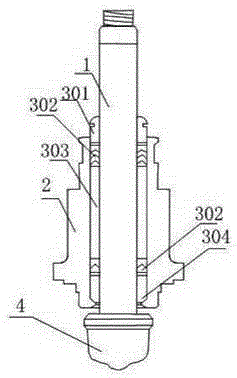

[0019] As shown in Figure 1, a packing sealing structure includes a valve body 2, a valve stem 1 arranged in the valve body 2, and a valve core 4 connected to the lower end of the valve stem 1, and is characterized in that it also includes a lower guide pipe 304, A lower packing ring 305 with 2~4 turns is arranged above the lower guide pipe 304, an intermediate sealing tube 303 is arranged above the lower packing ring 305, an upper packing ring 302 with 4~8 turns is arranged above the middle sealing pipe 303, and the upper packing ring 302 An upper guide pipe 301 is arranged above, and the upper guide pipe 301, the lower guide pipe 304, the lower packing ring 305, the upper packing ring 302 and the intermediate sealing pipe 303 are all sleeved on the valve stem and contacted in the valve body.

[0020] The setting of the upper and lower guide pipes can stabilize the valve stem from both ends, prevent excessive vibration of the valve stem, and enhance the stability of the valve ...

Embodiment 2

[0022] As shown in FIG. 1, both the lower packing ring 305 and the upper packing ring 302 are provided with a V-shaped layer or an O-shaped layer of polytetrafluoroethylene or perfluororubber. The outside of the V-shaped layer or the O-shaped layer of the lower packing ring 305 and the upper packing ring 302 is carburized polytetrafluoroethylene or polyether ether ketone.

[0023] The O-shaped sealing ring is low in cost, good in sealing performance, wide in application range, simple in structure and has a self-sealing effect, often only one seal can be used to complete the sealing, the sealing effect is good, and its sealing performance remains unchanged when used for reciprocating motion sealing. Medium leakage is very small. The V-shaped sealing ring is a lip-shaped sealing ring. In the free state, the outer diameter of the lip of the V-shaped sealing ring is larger than the inner diameter of the packing cavity, and the inner diameter of the lip is smaller than the outer di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com