Rapid mixing tubular flame burner with axial jet

A jet and tubular technology, applied in the field of rapid mixing tubular flame burners, can solve the problems of cracked flame synthesis nanomaterial yield, cutting surface defects, uneven heating, etc., achieve good dynamic characteristics and thermal stability, and reduce the generation of cracks , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better illustrate the purpose and advantages of the present invention, the specific implementation manners of the present invention will be further described below in conjunction with the drawings.

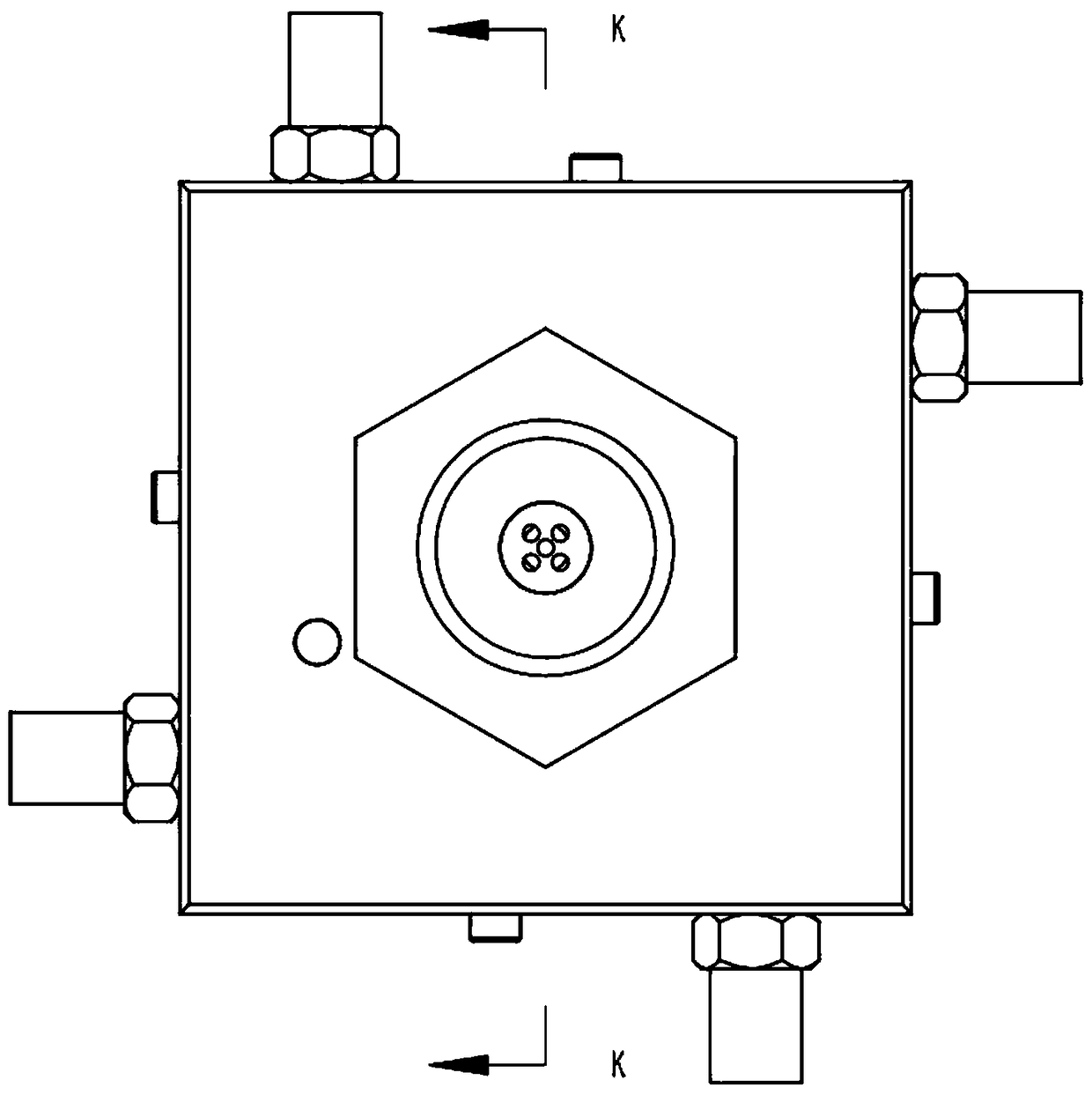

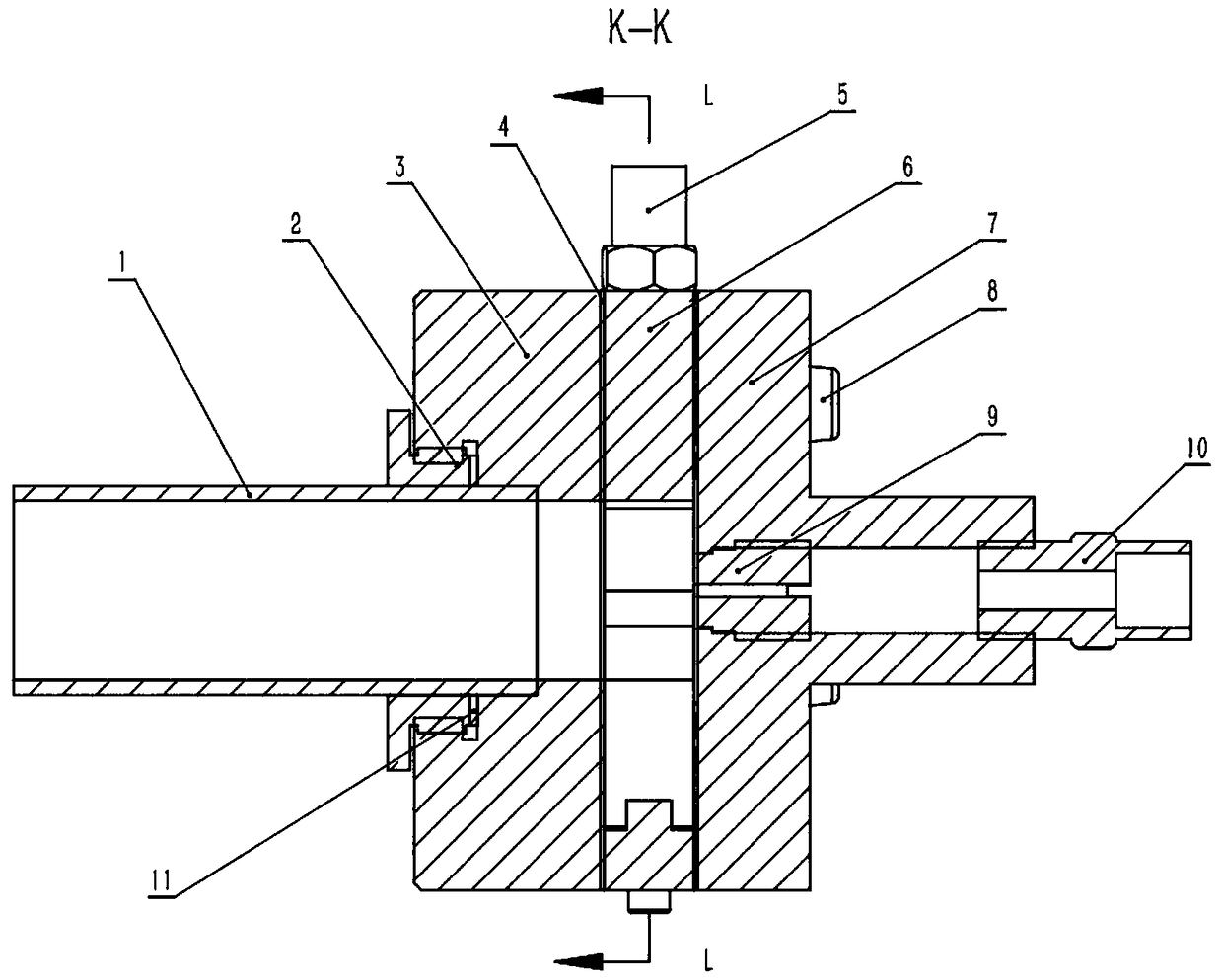

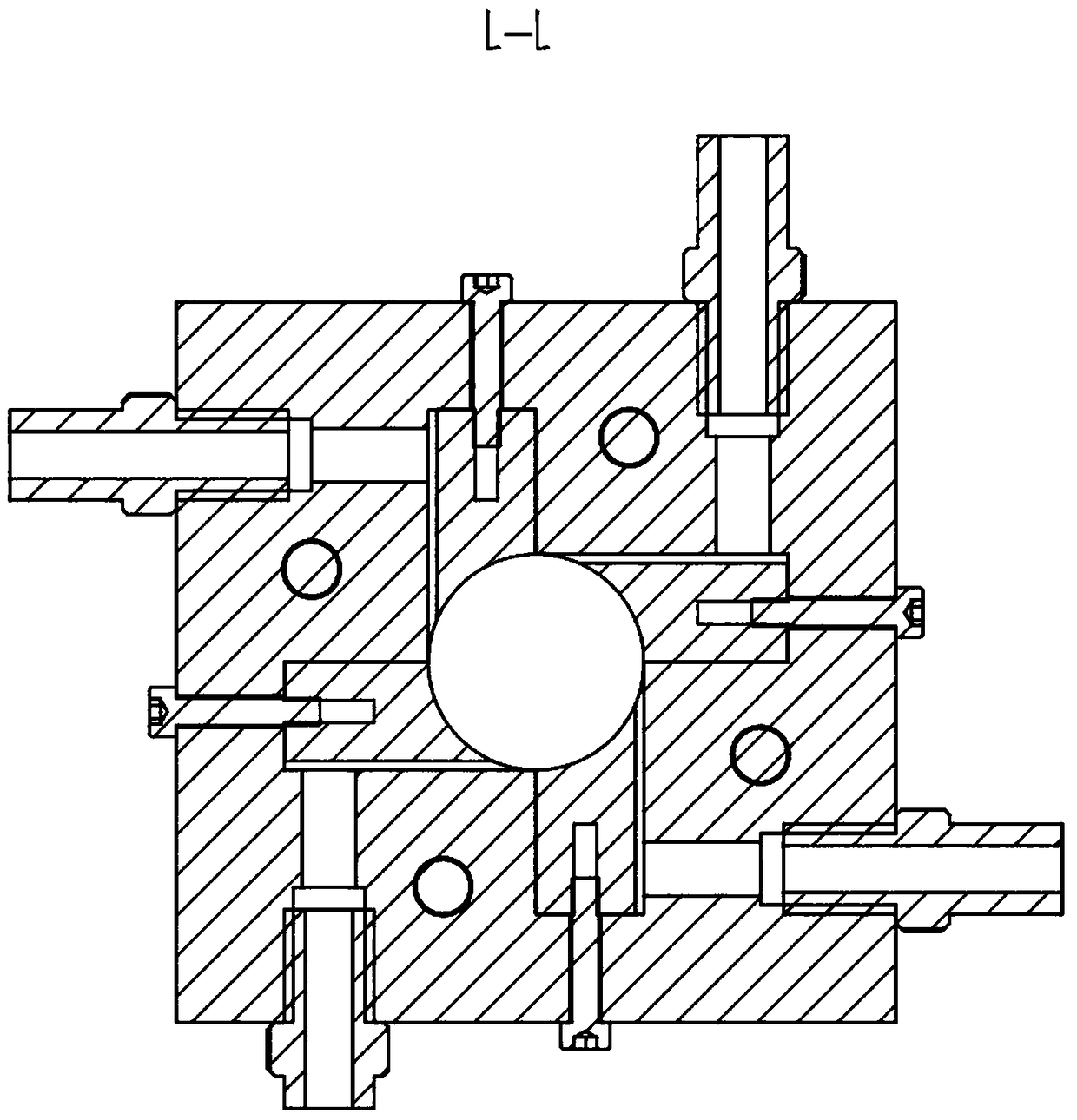

[0031] A rapidly mixing tubular flame burner with axial jet flow, the main components include: quartz glass tube 1, glass tube fixing sleeve 2, copper gasket 11, front cover body 3, copper gasket 4, swirler 6, Back cover body 7, nozzle 9, pipe joint 10, fixing bolt 8 etc. are formed.

[0032] The front cover body 3 and the quartz glass tube 1 adopt a transition fit, the copper gasket 10 is inserted into the quartz glass tube 1, and the glass tube fixing sleeve 2 is inserted into the quartz glass tube 1 and the burner front cover body 3 is connected by threads; There are N1 tangential inlet slits inside the device 6, which are tangent to the circular combustion chamber in the middle of the swirler 6, and N1 pipe joints 5 are connected to the outside of the swirle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com