Tangential inlet hybrid-tube-shaped flame burner

A flame combustion and burner technology, applied in the field of combustion, can solve problems such as unfavorable burner working for a long time, releasing a lot of heat, and flame instability, so as to prevent backfire or even explosion, reduce heat loss, and reduce heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better illustrate the purpose and advantages of the present invention, the present invention will be described in detail below with reference to the drawings and in conjunction with the embodiments.

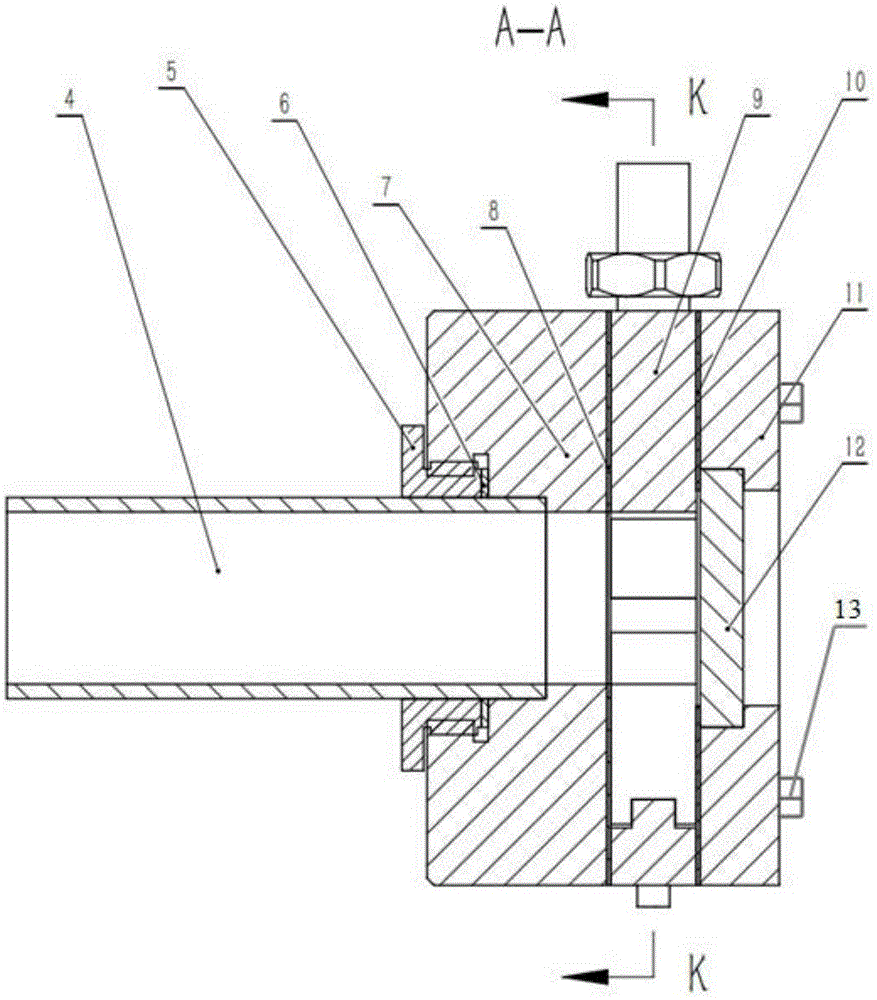

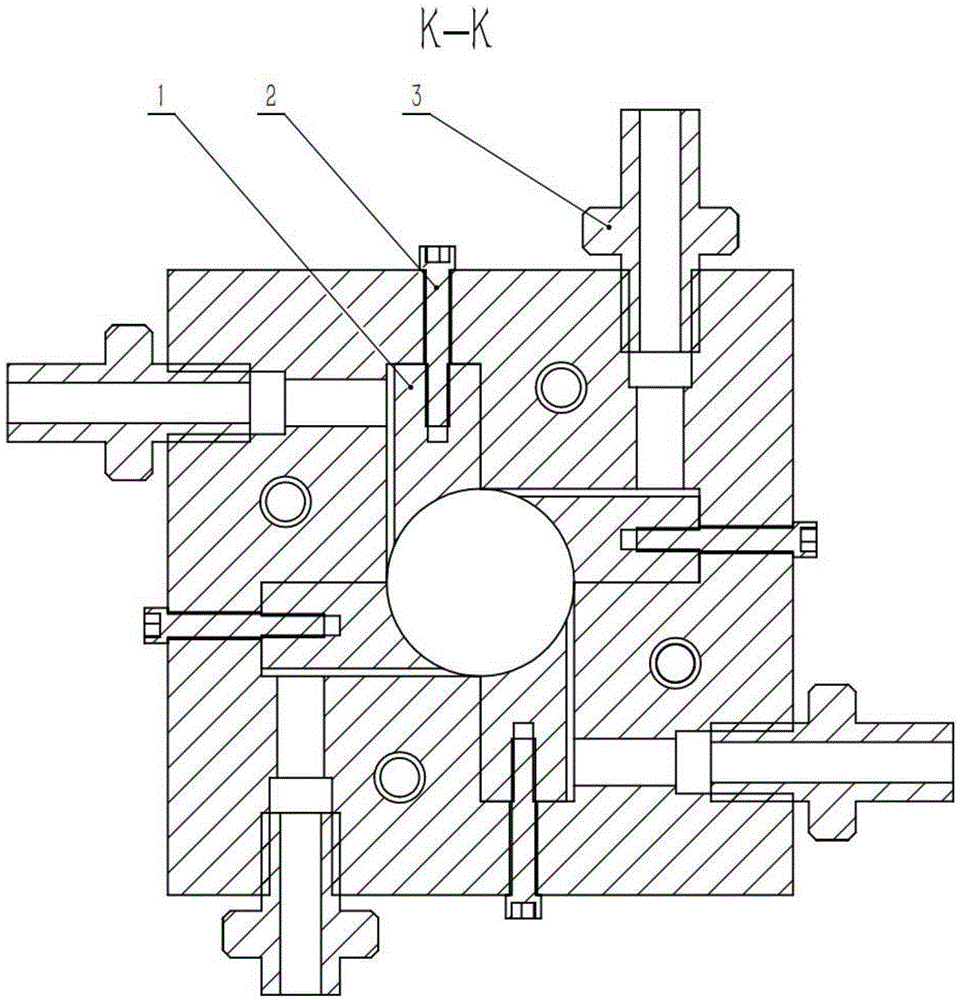

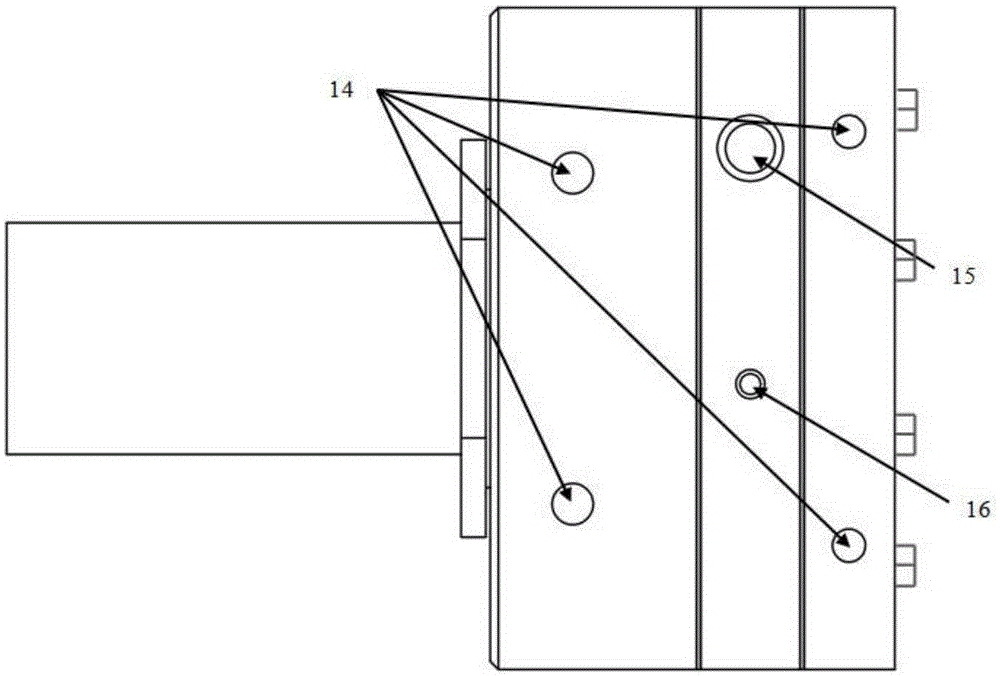

[0028] One or more types of fuel and oxidant tangentially flow into the mixed tubular flame burner. The main components include the front cover body 7, the swirl frame 9, the rear cover body 11, the fastening bolts 2, and the fastening bolts 13. , Adjustment block 1, quartz glass sheet 12, quartz glass tube 4, copper gasket 6, copper gasket 8, copper gasket 10, adapter 3, glass tube fixing sleeve 5 and so on.

[0029] Such as figure 2 As shown, N1 adjustment blocks 1 are connected to the swirl frame 9 through N1 fastening bolts 2 and a gap with a width of XX will be formed between the adjustment blocks 1 and the swirl frame 9, and N1 adjustment blocks 1 The arc surface and the inner surface of the swirl frame 9 are combined to form a circular surface; after install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com