Automatic gas stove oil fume adsorption method

A gas stove and oil fume technology, which is applied in the field of gas stoves, can solve problems such as high cost, and achieve the effects of reducing costs, ensuring safety, and reducing space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

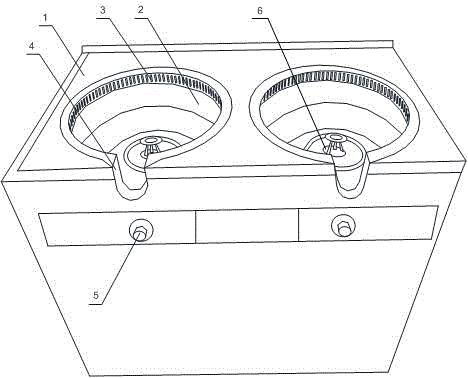

[0020] Such as figure 1 As shown, this embodiment includes a cooker body panel 1 and a burner. The middle part of the cooker body panel 1 is provided with a conical cavity 2 sunken downwards, and a U-shaped groove 4 is also opened on the cooker body panel 1. The cavity 2 communicates with the outside world through a U-shaped groove 4. The bottom of the cavity 2 is equipped with a burner, and also includes a plurality of smoking holes 3 and fans. within 1. The panel 1 of the cooker body adopts a conical cavity 2 sunken downwards. The cavity 2 is connected to the outside world through a U-shaped groove 4. The bottom of the cavity 2 is installed with a combustion system. Hole 3, place the pot at the bottom of the cavity 2 when in use, and the handle of the pot can be placed in the U-shaped groove 4. Under the adjustment of the switch 5, the combustion system starts to ignite, and the fan starts to absorb the generated smoke through the numerous smoking holes 3. so that the pres...

Embodiment 2

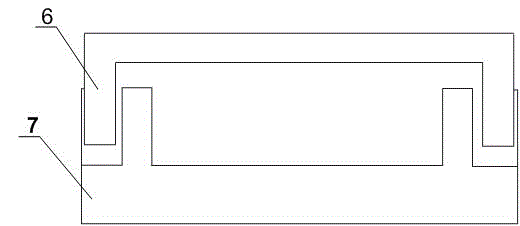

[0022] Such as figure 1 As shown, the present embodiment is based on Embodiment 1, because the cooker head panel 1 is connected to the burner, and the burner includes a burner head 7 and a fire cover 6, so a plurality of openings are provided at the bottom of the cavity 2, and the burner The head 7 is bolted to the bottom of the cavity body 2 through the opening, and the opening is turned up, and the height of the turning is greater than 2mm, so as to prevent overflowing liquid from flowing into the stove.

[0023] The top of the fire cover 6 is provided with a thermocouple type flameout protection device. When the control switch 5 button is ignited with a small fire, the thermocouple is heated by its flame to generate thermoelectric potential, which is introduced into the electromagnetic coil through the wire, and a magnetic field is generated to make the electromagnetic valve close, the gas valve opens, and the combustion path is opened to maintain its normal combustion ;On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com