Multi-supply central return pipe vertical buried pipe heat exchanger

A technology of return pipes and heat exchangers, which is applied in the field of vertically buried pipe heat exchangers in the central return pipe for multi-supply, can solve the problems that hinder the popularization and application of ground source heat pump systems, increase the initial investment of ground source heat pump systems, and reduce the cost of supply and return pipes Inter-thermal short-circuit and other problems can be achieved to reduce thermal interference, save floor space, and avoid heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a vertical buried tube heat exchanger with two supply and one return central return pipes.

[0027] Such as Figure 1~4 As shown, there are two vertical water supply branch pipes, and the same number of water supply straight pipes are provided on the bottom cylindrical joint.

[0028] The heat exchanger includes a water collector 1, a water supply straight pipe 2, a return water straight pipe 5, a casing straight pipe 8, a water supply branch pipe 4, a return pipe 7, a casing pipe 10, and a rib plate 11. At the bottom of the water collector, the upper part of the water collector 1 is a cylindrical structure, and the lower part is a conical structure; two vertical water supply branch pipes 4 and a vertical return water pipe 7 are arranged on the upper part of the heat exchanger; the return water pipe 7 and the outer casing 10 Composed of a coaxial pipe-in-pipe, the return pipe 7 and the outer casing 10 are separated by pipe clips 12 every 3m in ...

Embodiment 2

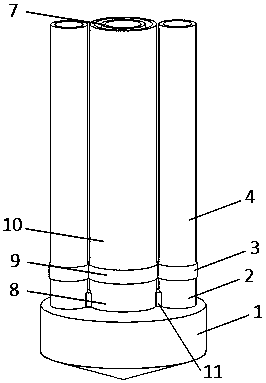

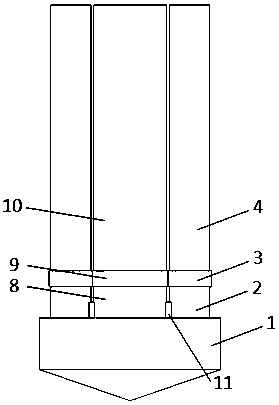

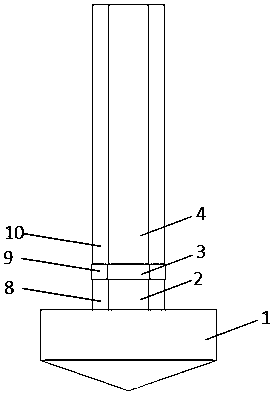

[0035] This embodiment provides a vertical buried tube heat exchanger with three supply and one return central return pipes.

[0036] Such as Figure 5~8 As shown, there are three vertical water supply branch pipes, and the same number of water supply straight pipes are arranged on the bottom cylindrical joint.

[0037] The heat exchanger includes a water collector 1, a water supply straight pipe 2, a return water straight pipe 5, a casing straight pipe 8, a water supply branch pipe 4, a return pipe 7, a casing pipe 10, and a rib plate 11. At the bottom of the water collector, the upper part of the water collector 1 is a cylindrical structure, and the lower part is a conical structure; three vertical water supply branch pipes 4 and one vertical return water pipe 7 are arranged on the upper part of the heat exchanger; the center of the return water pipe 7 and the center of the heat exchanger The center overlaps, and the three water supply branch pipes 4 are evenly distributed ...

Embodiment 3

[0040] This embodiment provides a vertical buried tube heat exchanger with four supply and one return central return pipes.

[0041] Such as Figure 9~11 As shown, there are 4 vertical water supply branch pipes, and the same number of water supply straight pipes are arranged on the bottom cylindrical joint.

[0042]The heat exchanger includes a water collector 1, a water supply straight pipe 2, a return water straight pipe 5, a casing straight pipe 8, a water supply branch pipe 4, a return pipe 7, a casing pipe 10, and a rib plate 11. At the bottom of the water collector, the upper part of the water collector 1 is a cylindrical structure, and the lower part is a conical structure; four vertical water supply branch pipes 4 and a vertical return water pipe 7 are arranged on the upper part of the heat exchanger; the center of the return water pipe 7 and the heat exchanger The centers of the four water supply branch pipes 4 are evenly distributed around the middle pipe of the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com