Cylindrical group printed circuit board microchannel refrigeration device

A technology for printed circuit boards and refrigeration devices, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of small air intake, low heat transfer efficiency, and restrictions on the application and development of J-T effect refrigerators, and achieve compactness Improve the degree, ensure reliability, and weaken the effect of axial heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

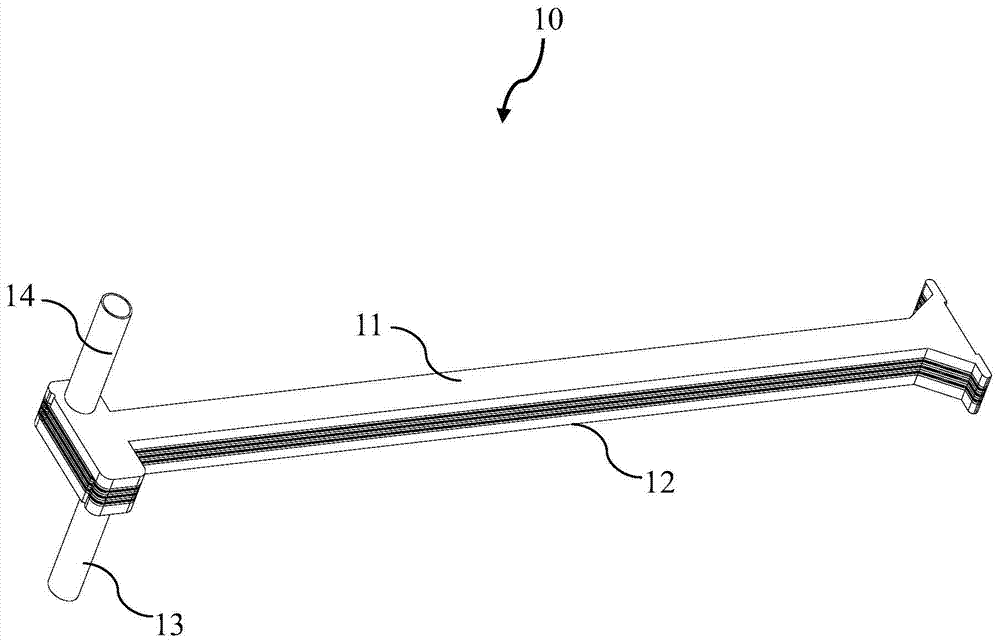

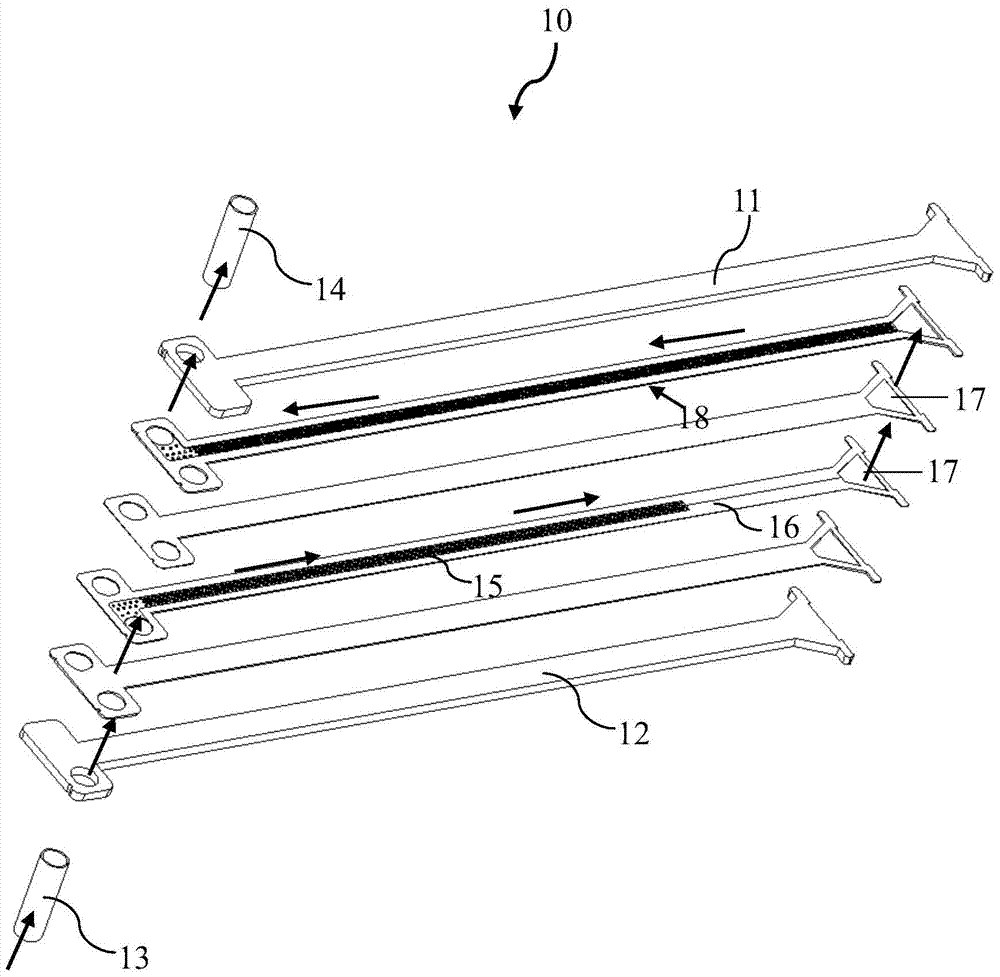

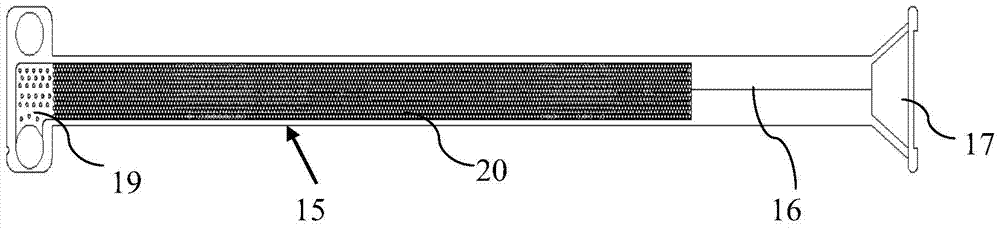

[0027] figure 1 It is a schematic diagram of the appearance structure of the column group printed circuit board type micro-channel refrigeration device of this embodiment. Such as figure 1 As shown, the cylindrical group printed circuit board microchannel refrigerator 10 includes a cover plate 11 , a bottom plate 12 , a mass-inlet unit 13 and a mass-out unit 14 . The cover plate 11 and the base plate 12 respectively cover the upper end and the lower end of the micro-channel refrigeration device 10, and the mass-incoming unit 13 and the mass-exiting unit 14 are all vertically arranged on the left side of the micro-channel refrigeration device 10, and are connected with the base plate 12 and the cover plate 11 respectively. They are connected to each other for refrigerant to enter and exit the micro-channel refrigeration device 10 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com