Method for determining manufacturing technological conditions of standard varicosity membranes by testing oil contents of varicosity membranes

A technology of production process and process conditions, applied in the direction of weighing by removing certain components, can solve the problems of detection of hydrocarbon-containing substances, detection of hydrocarbon substances, unqualified test results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

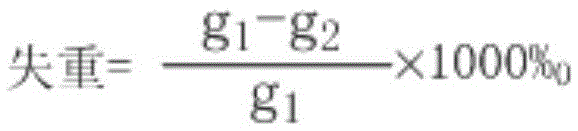

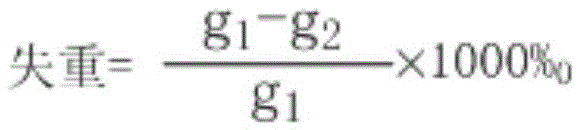

Method used

Image

Examples

Embodiment

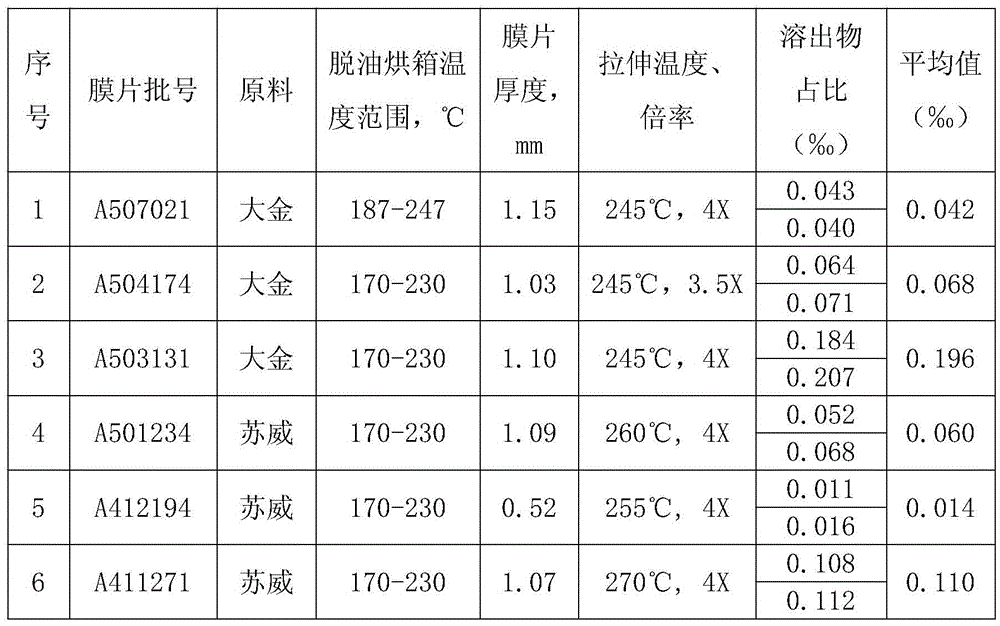

[0037] 1. Carry out the oil content test experiment (also known as "dissolution test") for several kinds of bulky diaphragms of different batch numbers (hereinafter referred to as the diaphragm) according to the above method, and the experimental data obtained are as follows:

[0038]

[0039] 2. Experimental data analysis and conclusion:

[0040] 1) The thickness of the diaphragm has a great influence on the oil content. The thickness of the diaphragm of No. 5 sample (A412194) is 0.52mm, and the measured data of the oil content is 0.014‰, which is far smaller than the measured data of the oil content of other diaphragms.

[0041] Conclusion 1: Under the same process conditions, the thinner the diaphragm, the less the oil content of the diaphragm.

[0042] 2) Comparing No. 1 sample (A507021) and No. 3 sample (A503131), which are also large gold materials, the thickness of No. 1 sample is slightly larger than that of No. 3 sample. Under the same conditions, the temperature r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com