Cutting device for aerated bricks

A cutting device and a technology for aerated bricks, applied in the field of aerated brick manufacturing, can solve the problems of unqualified product quality, low production efficiency of cutting machines, adhesion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

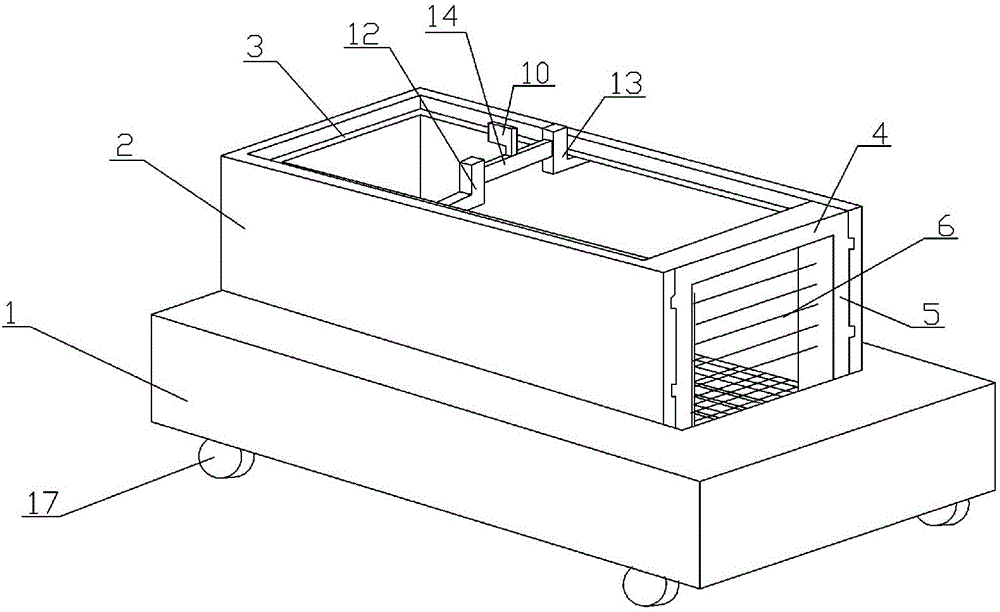

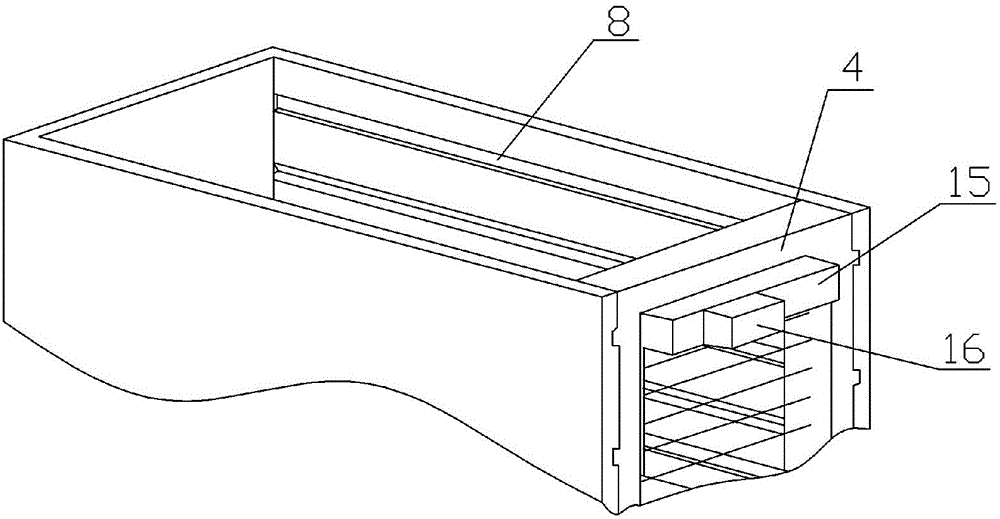

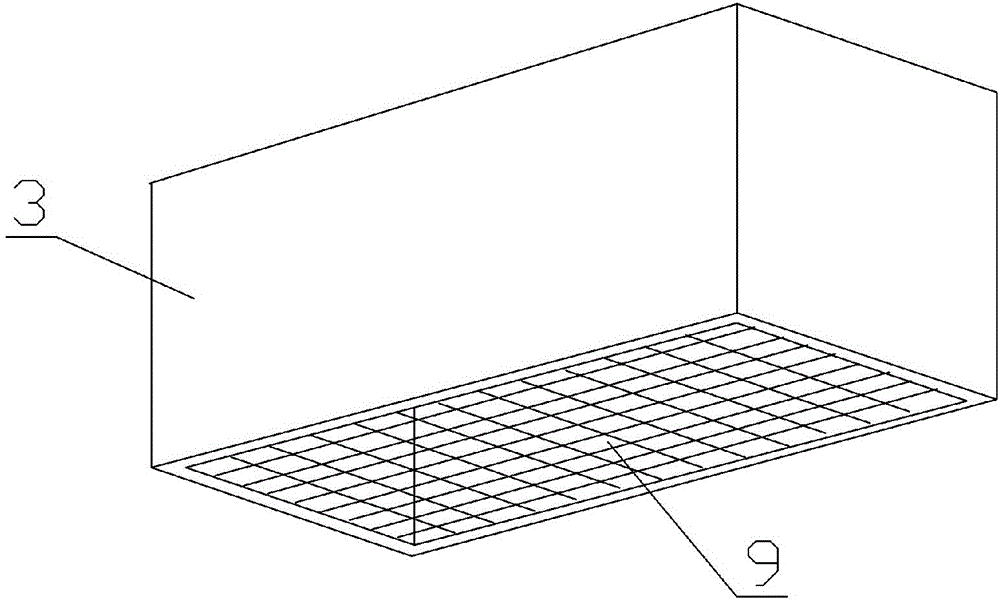

[0018] Embodiment 1 is basically as attached figure 1 , figure 2 Shown: a cutting device for aerated bricks, including a machine base 1, a transverse cutting frame 2 and a longitudinal cutting frame 3, the transverse cutting frame 2 and the longitudinal cutting frame 3 are arranged above the machine base 1, the transverse cutting frame 2 and the The vertical cutting frame 3 is a hollow cubic frame body, the horizontal cutting frame 2 is sleeved outside the vertical cutting frame 3, the horizontal cutting frame 2 is provided with a door frame-shaped mobile frame 4, and the two sides of the door frame-shaped mobile frame 4 are respectively provided with Columns 5, the first cutting steel wire group 6 is arranged between the columns 5, the first cutting steel wire group 6 includes several steel wires evenly distributed between the columns 5, the outer sides of the columns 5 on both sides of the door frame-shaped mobile frame 4 Be provided with slide block 7, be provided with ch...

Embodiment 2

[0022] Such as Figure 4 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, and the difference is that the uprights 5 on both sides of the doorframe-shaped mobile frame 4 are provided with pull rods 18 that pass through the transverse cutting frame 2, and the transverse cutting frame 2 There is a receiving groove 19 for accommodating the pull rod 18, the pull rod 18 is connected to a power device such as a cylinder, and the setting of the pull rod 18 can be used as the force point for the cylinder to pull / promote the door frame-shaped mobile frame 4, thereby driving the door frame-shaped mobile frame 4. The first cutting wire group 6 cuts the aerated brick. And pull rod 18 can be installed a plurality of along the vertical direction of column 5, and each pull rod 18 is all connected with cylinder, and so just can guarantee that the pulling force of cylinder to door frame shape mobile frame 4 is comparatively even in the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com