Method for measuring electrolyte distribution in lithium ion battery core

A lithium-ion battery and a measuring method are applied in the field of measuring the electrolyte distribution in a lithium-ion battery core, and can solve the problems affecting the safety and service life of the battery, and the lithium deposition of the battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

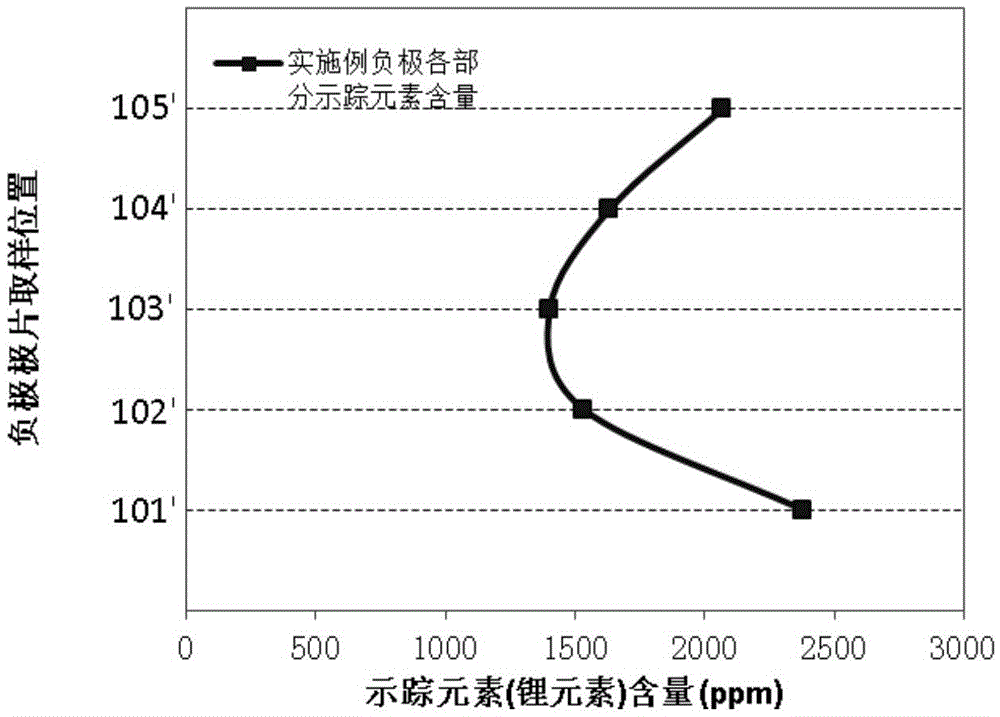

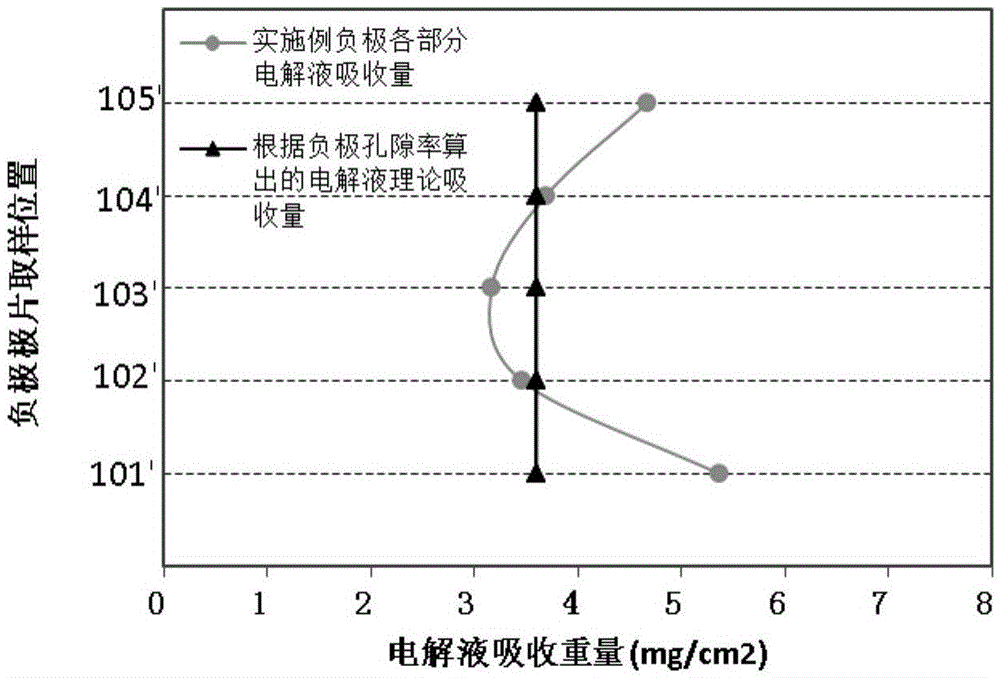

[0046] The measurement of electrolyte distribution on the negative pole sheet in embodiment 1 lithium-ion battery core

[0047] 1. Prepare two groups (experimental group and control group) of V0D5N0 non-injected electrolyte batteries (length 220mm, width 135mm, thickness 29mm, steel case), wherein the electronic insulating film uses polyethylene film with surface ceramic treatment ; The positive electrode active material is LiFePO 4 ; The active material of the negative pole piece is graphite; the electrolyte formula containing tracer elements is a chain carbonate, and the lithium salt is 1MLiPF 6 .

[0048] 2. According to the normal battery processing procedure, inject 300g of electrolyte solution containing 1mol / L lithium hexafluorophosphate salt, and the trace element is lithium element in lithium hexafluorophosphate salt. Among them, the experimental group made the battery before charging according to the normal battery processing procedure, and the control group direct...

Embodiment 2

[0061] Determination of electrolyte distribution on the negative pole sheet in embodiment 2 lithium-ion battery core

[0062] 1. Prepare two groups (experimental group and control group) of V0D5N0 non-injected electrolyte batteries (220mm in length, 135mm in width, 29mm in thickness, aluminum shell), in which the electronic insulating film uses a polyethylene film with surface ceramic treatment ; The positive electrode active material is LiFePO 4 ; The active material of the negative electrode is hard carbon; the electrolyte formula containing tracer elements is a chain carbonate, and the lithium salt is 1MLiPF 6 .

[0063] 2. Inject 300g of electrolyte solution containing 1mol / L lithium hexafluorophosphate salt according to the normal battery processing procedure, and the trace element is iron. Among them, the experimental group made the battery before charging according to the normal battery processing procedure, and the control group directly charged to the full state.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com