In-situ capture heterogeneous catalytic reaction intermediate product device and use method thereof

A heterogeneous catalysis and reaction technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of inability to provide sufficient reaction mechanism research, insufficient data, and inability to achieve real-time online monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

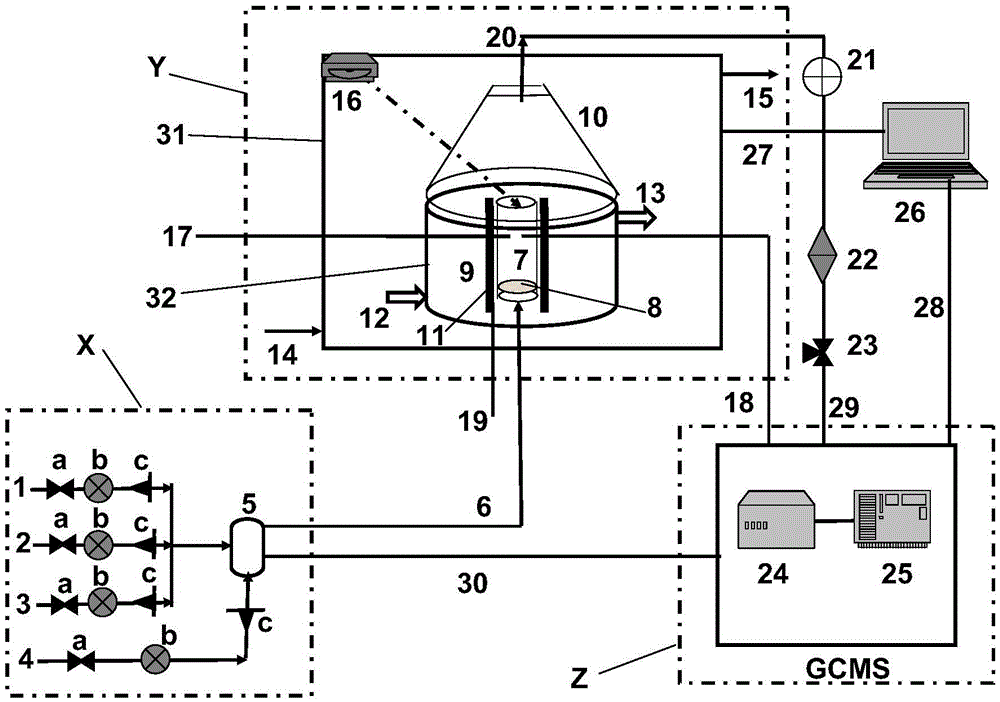

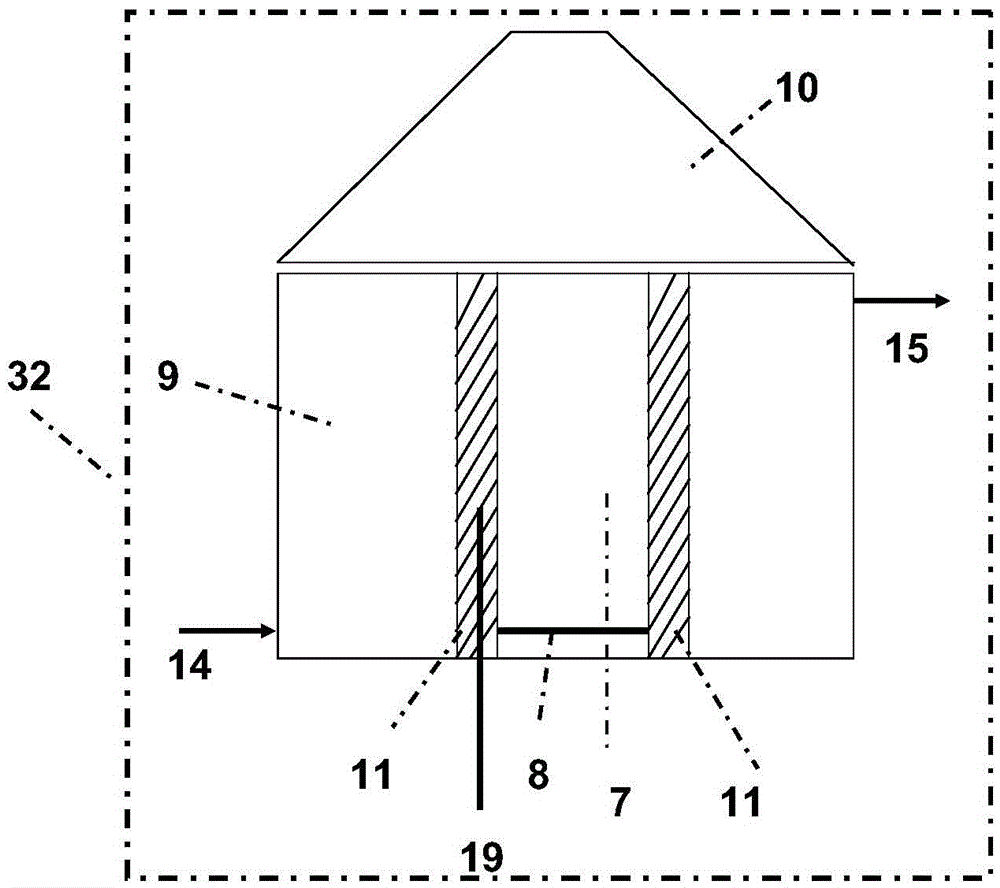

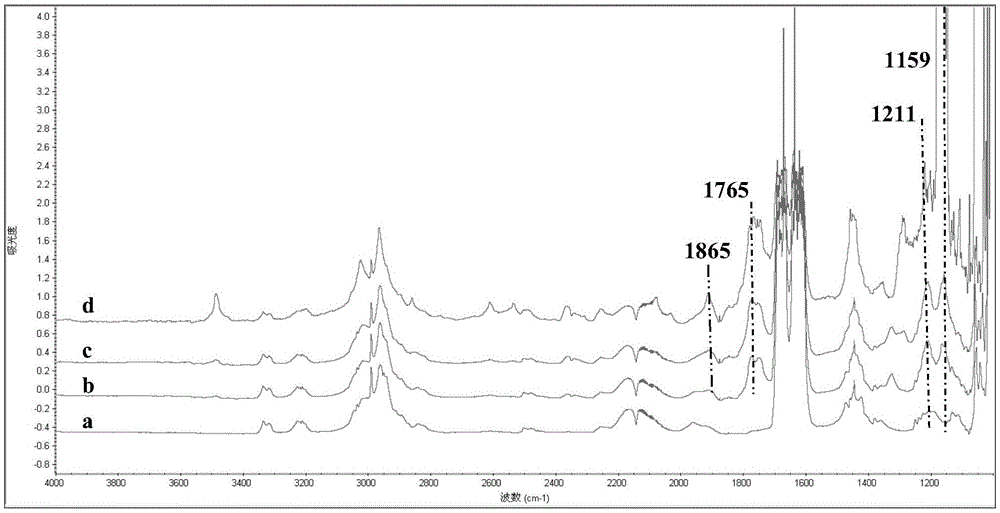

[0045] Embodiment 1: CO and MN (methyl nitrite) in Pd-Al 2 o 3 Reaction studies on catalysts.

[0046] After grinding to 120 mesh Pd-Al 2 o 3 Load the catalyst into the in-situ infrared reaction cell 7, insert the thermocouple 17 and the mass spectrometer probe 18 into the in-situ reaction cell 7, flatten the catalyst on the surface of the in-situ infrared reaction cell body, cover the in-situ cell cover 10, and tighten the screws Put it into the in-situ reaction box 31, connect the reaction gas circuit 1 (connect the CO gas circuit) and 2 (connect the MN gas circuit), 3 (connect the reducing gas H 2 Gas path), 4 (connected to inert gas N 2 ), pass the purge gas N into the box through 14 2 , into N through gas path 4 2 Purge the reaction tank, pass cooling water through 12, connect the heating circuit and in-situ infrared emission source circuit, gradually heat up to 80°C after purging for 10 minutes, gradually reduce the gas flow rate in 4, and gradually pass in H throu...

Embodiment 2

[0050] Example 2: CO, H 2 and O 2 In Pd-Al 2 o 3 Reaction studies on catalysts.

[0051] After grinding to 300 mesh Pd-Al 2 o 3 Load the catalyst into the in-situ infrared reaction cell 7, insert the thermocouple 17 and the mass spectrometer probe 18 into the in-situ reaction cell 7, flatten the catalyst on the surface of the in-situ infrared reaction cell body, cover the in-situ cell cover 10, and tighten the screws Put it into the in-situ reaction box 31, connect the reaction gas path 1 (connected to the CO gas path) and 2 (connected to the H 2 gas path), 3 (connected to O 2 Gas path), 4 (connected to inert gas N 2 ), pass the purge gas N into the box through 14 2 , into N through gas path 4 2 Purge the reaction tank, pass cooling water through 12, connect the heating circuit and the in-situ infrared emission source circuit, gradually heat up to 50°C after purging for 10 minutes, gradually reduce the gas flow rate of 4, and gradually pass through 1, 2, 3 into the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com