Improved light resistance pre-baking oven heating device

A heating device and pre-baking technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as poor baking effect, affecting the production quality of liquid crystal display devices, and maintaining uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are examples, but the contents of the present invention are not limited to the scope of these examples.

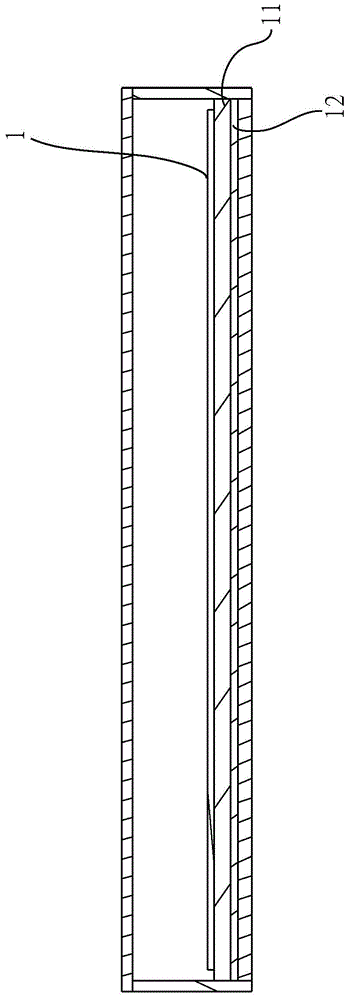

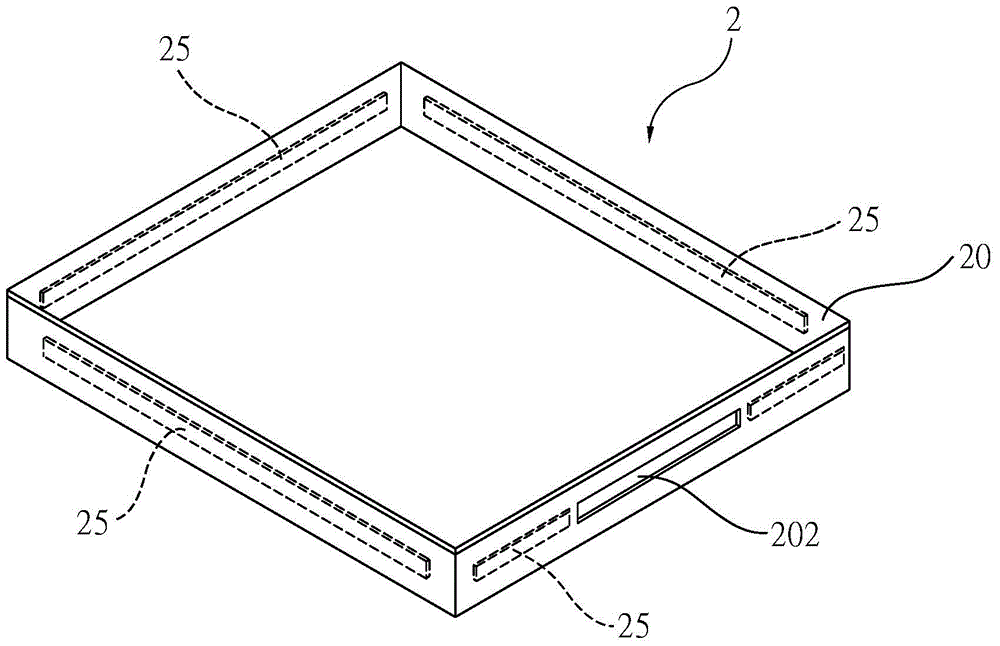

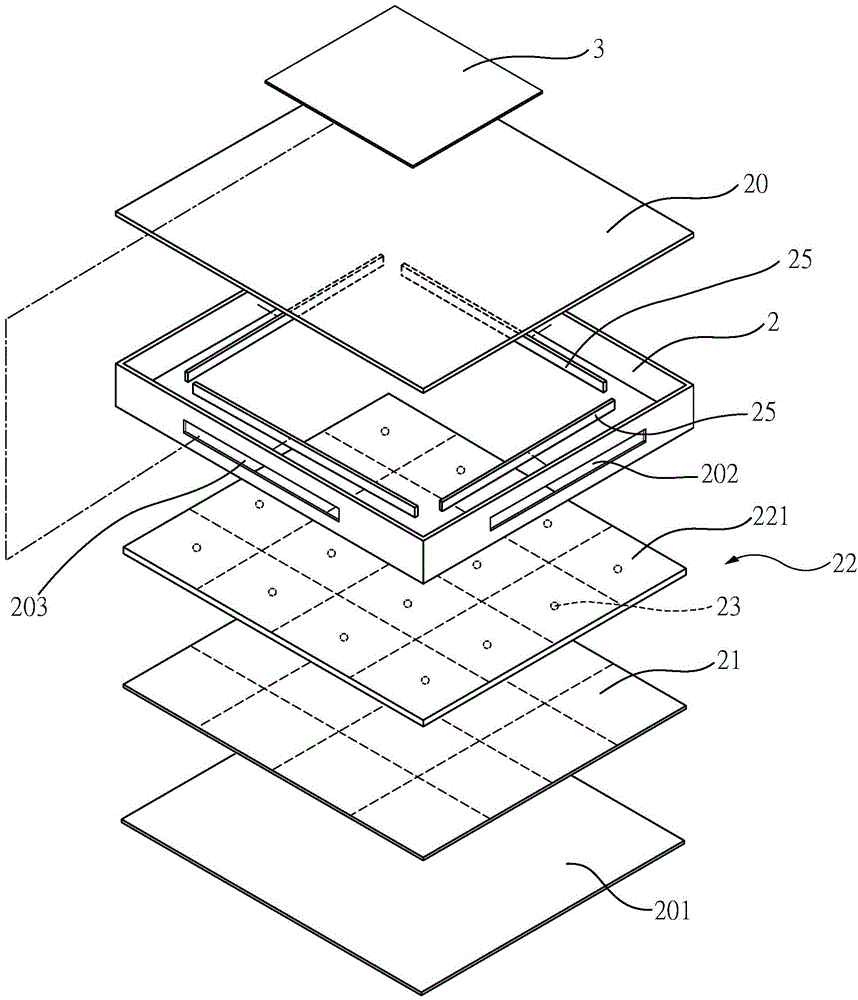

[0016] An improved photoresist pre-baking furnace inner ring edge heater of the present invention, first of all, please refer to figure 2 and cooperate image 3 As shown, it is mainly composed of a cavity 2, a heater 21, a hot plate 22, a temperature sensor 23 and an inner ring edge heater 25. The cavity 2 is in the shape of a tank, and the bottom is a support base plate 201, and An upper cover plate 20 can be covered on the top surface to form a closed heating space. An inlet 203 is provided on one side of the cavity 2 for placing the glass substrate 3, and an air exhaust port 202 is opened on either side. And a heater 21 is provided above the support base plate 201, which can heat the hot plate 22 on the heater 21, and the hot plate 22 is divided into a plurality of small partitions 221, which are projected by a plurality of independent heaters 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com