Electro-hydraulic servo valve feedback controller

An electro-hydraulic servo valve and controller technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as insufficient performance, high output pressure, excessive vibration of servo valve output pressure, etc., to improve stability and accuracy, response speed improvement, and the effect of solving the output pressure swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

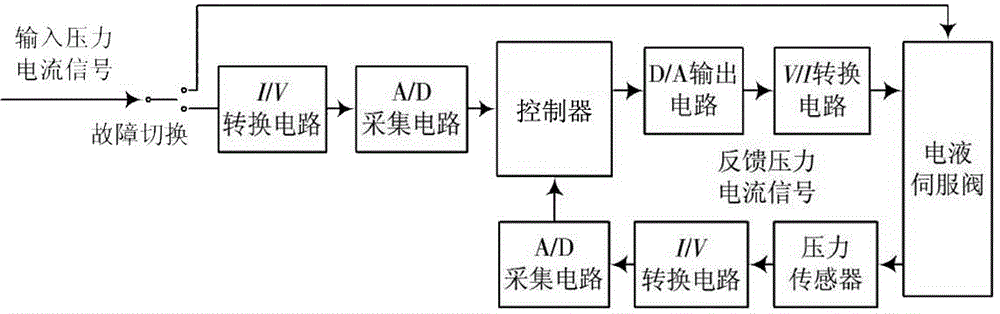

[0012] An electro-hydraulic servo valve feedback controller is characterized in that it includes a controller, a pressure sensor and a peripheral circuit; wherein the peripheral circuit includes an input signal acquisition circuit, a current signal output circuit and a fault switching circuit; an input signal acquisition circuit, a current signal output circuit Both the controller and the failover circuit are connected to the controller; the controller is a single-chip microcomputer based on ATmega16, and ATmega16 adopts an advanced RISC structure, and the code execution speed is high, and the work is reliable and stable.

[0013] In the feedback controller of an electro-hydraulic servo valve according to the present invention, the input signal acquisition circuit includes an I / V conversion circuit and an A / D acquisition circuit, so as to convert a 4-40mA current into a 0-5V that can be collected by a single-chip microcomputer Voltage. The current signal output circuit include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com