Liquid cooling system for avionic device

A kind of avionics equipment, liquid cooling technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of increasing aircraft compensatory loss, affecting aircraft aerodynamic shape, etc., to achieve the reduction of compensatory loss, simple structure, and thermal energy optimization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

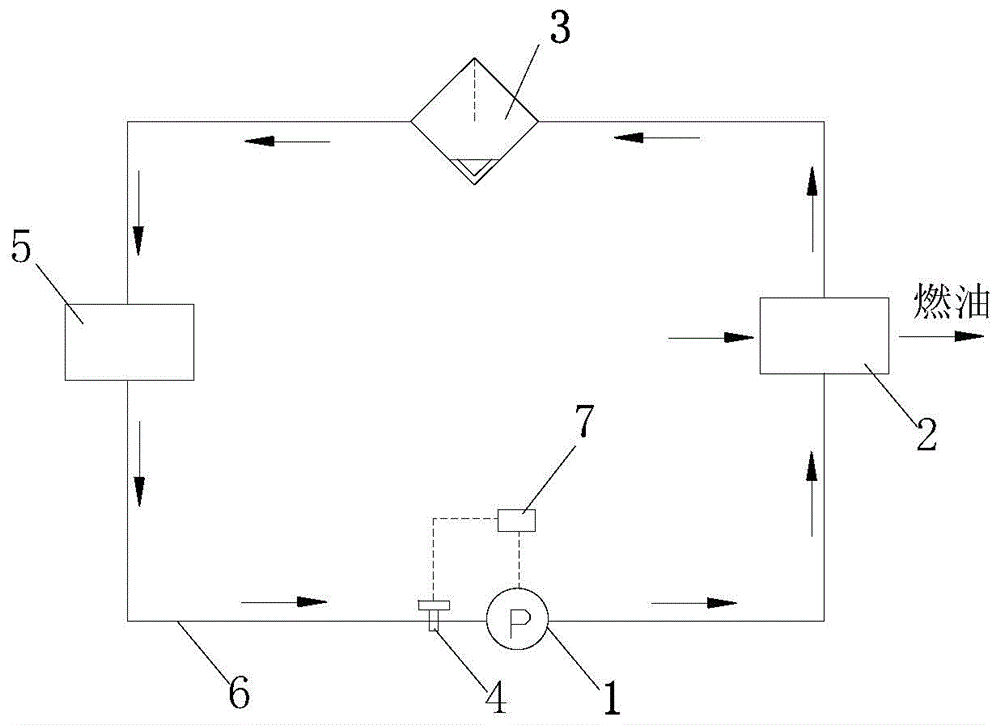

[0012] see figure 1 , the liquid pump 1, the liquid-liquid radiator 2, the gas-liquid separator 3 and the electronic equipment 5 are connected in sequence through the pipeline 6, and the temperature sensor 4 is arranged on the conduit downstream of the electronic equipment 5, and the controller 7 is connected with the electronic equipment 5 through the control line. The temperature sensor 4 is connected to the liquid pump 1 .

[0013] A closed liquid circulation cooling system is adopted. The liquid pump 1 provides circulation power for the flow of the coolant in the system pipeline 6. The coolant passes through the cold plate to take away the heat generated by the electronic equipment 5, and then enters the liquid-liquid radiator 2 to be fueled. Cooling, the gas-liquid separator 3 set in the system also functions as a gas-liquid separator and an expansion tank. The controller 7 can automatically adjust the speed of the liquid pump 1 according to the liquid temperature measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com