Injector and contact element for the same

A contact element and injector technology, applied in electrical components, engine components, fuel injection devices, etc., can solve problems such as high cost and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

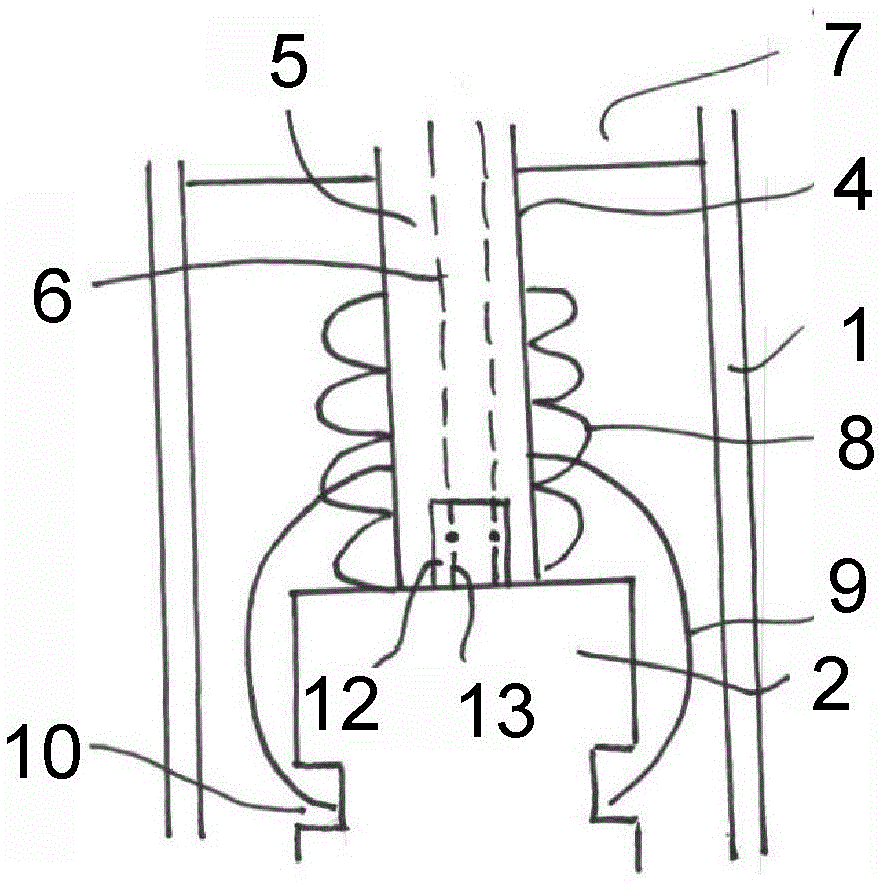

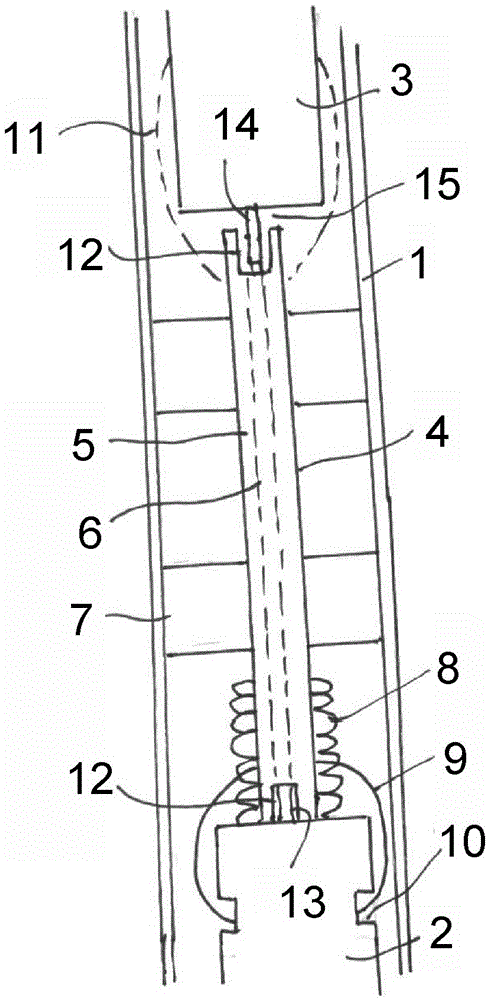

[0024] figure 1 A part of the injector body 1 with the piezoelectric actuator control unit 2 and with the connection plug 3 arranged on the head of the injector body 1 is shown. In order to allow actuation of the piezoelectric actuator control unit 2 , the latter is electrically connected to a connection plug 3 , which in turn is electrically connected to the control unit of the associated injection system of the internal combustion engine. By electrical pulses actuating the piezoelectric actuator control unit 2, the control unit 2 undergoes periodic length extension and contraction, which effect fuel injection via a not shown nozzle mechanism.

[0025] The electrical connection between the piezoelectric actuator control unit and the connection plug 3 is effected via a contact element 4 which has a conductor track 6 integrated into the insulating body 5 . In the exemplary embodiment shown here, as shown, two conductor tracks 6 are provided in the insulating body 5 which protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com