Stick shaped peanut crisp and preparation method thereof

A technology for peanut cakes and sticks, which is applied in confectionery, confectionery industry, food science and other directions, can solve the problems of inability to meet consumer needs, inconvenience to carry and eat, and the taste is not novel enough, so as to achieve novel taste and convenience for eating by hand. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

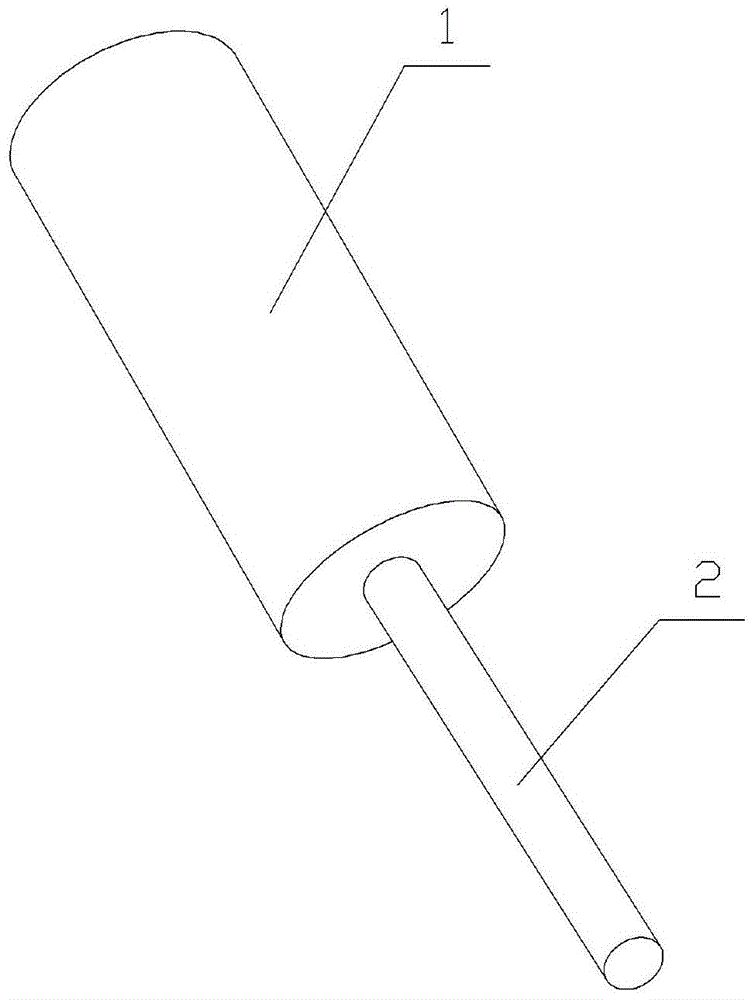

[0045] A stick-shaped peanut cake, see figure 1As shown, it includes a peanut crisp body 1 and a handle 2 fixedly arranged with the peanut crisp body; the peanut crisp body 1 is made of the following raw materials in parts by weight: 115 parts of malt syrup, 120 parts of white granulated sugar, 30 parts of fructose syrup 42 parts of palm oil, 300 parts of roasted peanuts, 32 parts of crispy cereals, 112 parts of puffed corn granules, 5 parts of white sesame seeds, 5 parts of black sesame seeds, 7.2 parts of edible salt, 0.3 parts of lecithin, and 2.5 parts of baking soda.

[0046] Among them, the crispy cereal flakes are made of the following raw materials in parts by weight: 8 parts of cornmeal, 2 parts of wheat flour, 1 part of whole wheat flour, 0.5 parts of whole oat flour, 1.3 parts of white sugar, 0.03 parts of edible salt, 0.1 part of calcium carbonate, water 1.1 parts. The puffed corn granules are made of the following raw materials in parts by weight: 0.4 parts of co...

Embodiment 2

[0068] A stick-shaped peanut crisp, comprising a peanut crisp body and a handle fixed to the peanut crisp body; the peanut crisp body is made of the following raw materials in parts by weight: 135 parts of malt syrup, 80 parts of white granulated sugar, fruit grape 40 parts of syrup, 36 parts of palm oil, 336 parts of roasted peanuts, 72 parts of crispy cereals, 72 parts of puffed corn granules, 20 parts of white sesame seeds, 20 parts of black sesame seeds, 5.6 parts of edible salt, 0.2 parts of lecithin, 3 parts of baking soda share.

[0069] Among them, the crispy cereal flakes are made from the following raw materials in parts by weight: 7 parts of cornmeal, 3 parts of wheat flour, 0.8 part of whole wheat flour, 1 part of whole oat flour, 1 part of white sugar, 0.04 part of edible salt, 0.2 part of calcium carbonate, water 1 serving. The puffed corn granules are made of the following raw materials in parts by weight: 0.5 parts of cornmeal, 7 parts of corn grits, 3 parts o...

Embodiment 3

[0080] A stick-shaped peanut crisp, comprising a peanut crisp body and a handle fixed to the peanut crisp body; the peanut crisp body is made of the following raw materials in parts by weight: 155 parts of malt syrup, 40 parts of white sugar, fruit grape 50 parts of syrup, 30 parts of palm oil, 372 parts of roasted peanuts, 112 parts of crispy cereals, 32 parts of puffed corn granules, 40 parts of white sesame seeds, 40 parts of black sesame seeds, 4 parts of edible salt, 0.1 parts of lecithin, 3.5 parts of baking soda share.

[0081] Among them, the crispy cereal flakes are made of the following raw materials in parts by weight: 6 parts of cornmeal, 4 parts of wheat flour, 0.5 part of whole wheat flour, 1 part of whole oat flour, 0.9 part of white sugar, 0.05 part of edible salt, 0.3 part of calcium carbonate, water 0.9 servings. The puffed corn granules are made of the following raw materials in parts by weight: 0.8 parts of cornmeal, 6 parts of corn grits, 4 parts of wheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com