Full-automatic stir-frying machine for nut food

A fully automatic stir-frying machine technology, applied in food processing, food science, application, etc., can solve the problems of difficult stir-frying operation, complex equipment structure, large energy consumption, etc., and achieve high stir-frying efficiency, good effect, The effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

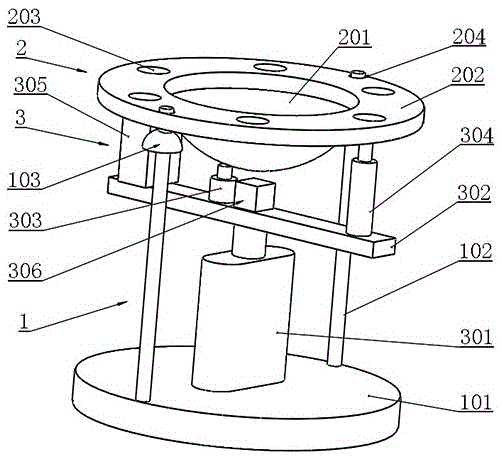

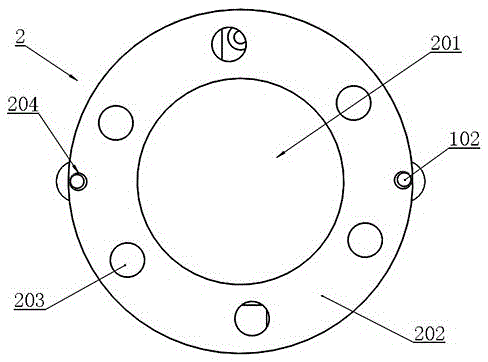

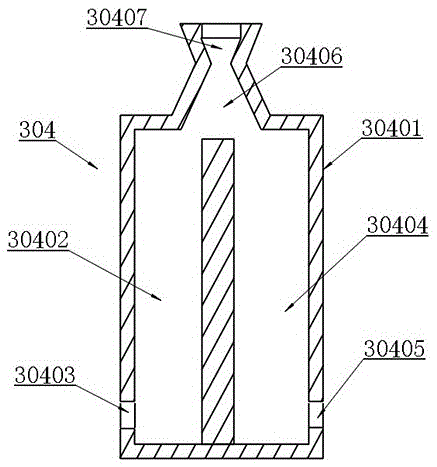

[0021] Example: as attached figure 1 , 2 and attached image 3 As shown, a fully automatic stir-fry machine for nuts, including a base 1, a stir-fry pan 2 arranged on the base 1 and a heating stir-fry pan arranged on the base 1 below the stir-fry pan 2 Unit 3, the heating and stirring unit 3 includes a rotating plate 302, a rotating motor 301 for driving the rotating plate 302 to rotate, a heating part 303 and an airflow jacking part 304 arranged on the rotating plate 302, by rotating The heated part 303 and the airflow lifting part 304 complete the heating and stir-frying operation. The heating part 303 heats the bottom of the nuts in the stir-frying dish, which has good heating effect and high heat utilization rate. Characteristically, the airflow jacking part 304 enables the stir-frying pan 2 to be lifted and lowered alternately to complete the stir-frying operation, which has the characteristics of effective and uniform stir-frying.

[0022] The stir-fry dish 2 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com