Flue gas desulfurization and dust removal method and device

A technology of desulfurization dust removal and mist removal device, which is applied in the field of flue gas treatment, can solve the problems of low flue gas temperature, high operating cost, large floor space, etc., and achieves the effects of high desulfurization efficiency, improved contact time and collision frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

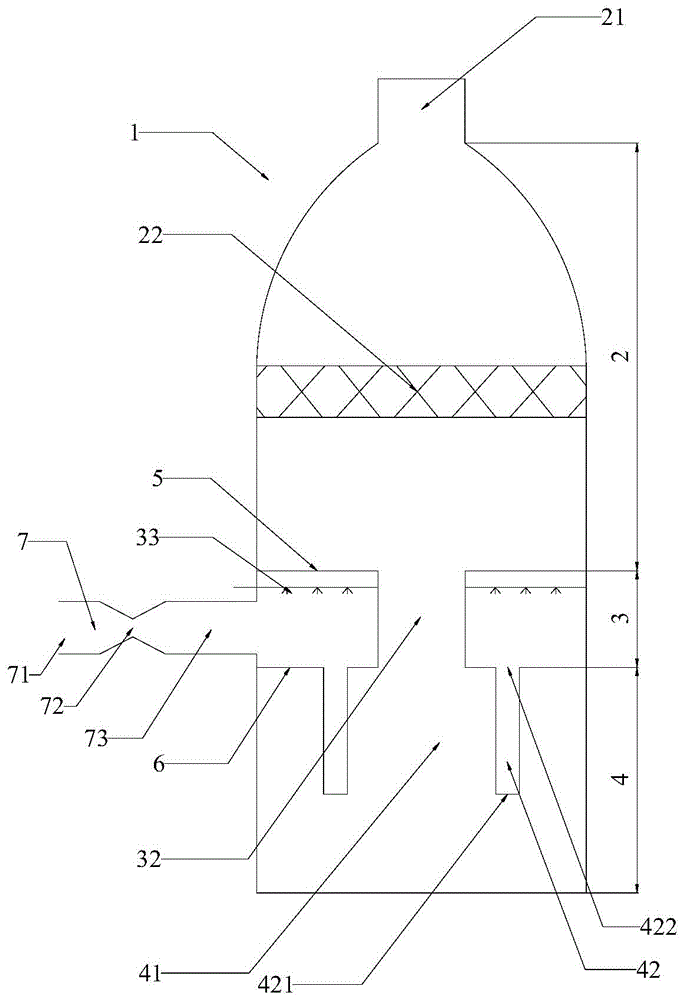

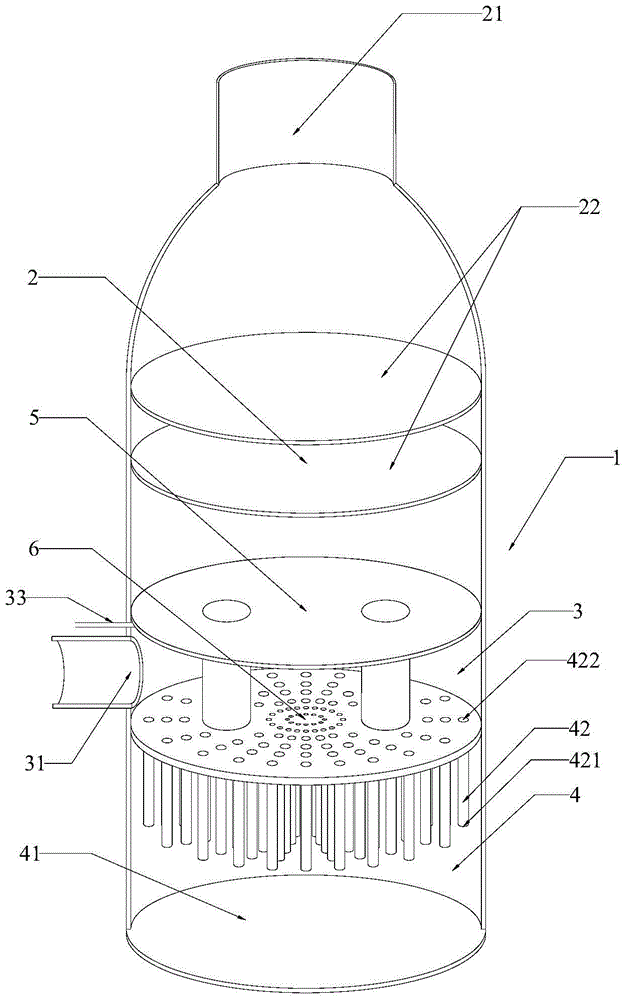

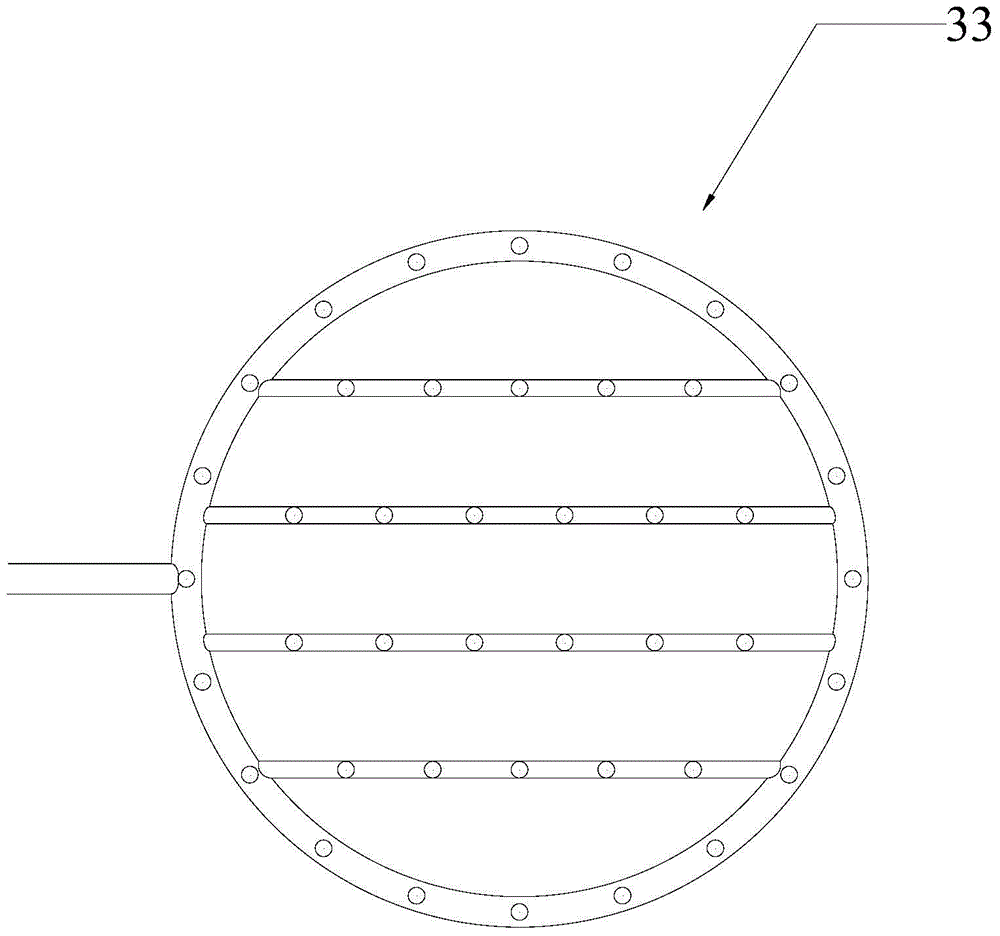

[0049] Such as Figure 1-3 As shown, the flue gas desulfurization and dust removal device of this embodiment includes a desulfurization tower 1, and the inner space of the desulfurization tower 1 is separated from top to bottom by a first partition 5 and a second partition 6 into mutually closed upper chambers 2, middle Bin 3 and lower bin 4, where the top of upper bin 2 is a flue gas discharge port 21, and the upper bin is equipped with a demister 22 from top to bottom; the middle bin 3 is equipped with a flue gas inlet 31 for introducing the flue gas to be treated into the desulfurization tower At least one flue gas passage 32 is set in the middle bin 3 for connecting the space between the upper bin 2 and the lower bin 4, the top of the middle bin 3 is provided with a spray device 33; the bottom of the lower bin 4 is arranged for storing flue gas desulfurizer The liquid reservoir 41 of the solution, the second dividing plate 6 between the middle chamber 3 and the lower chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com