Runner plate of crusher

A runner plate and crusher technology, applied in grain processing, etc., can solve the problems of reduced safety and reliability, reduced service life, low impact toughness, etc., and achieve the effects of increased service life, improved crushing effect, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

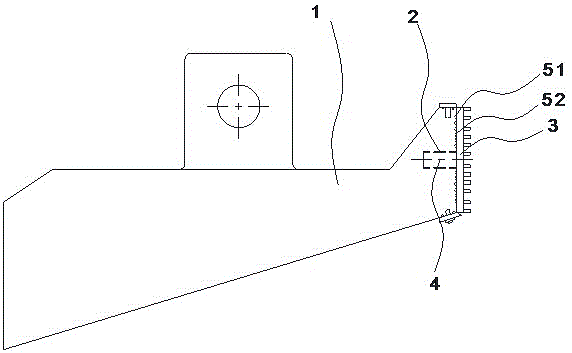

[0012] The present invention as figure 1 As shown, the flow channel plate body 1 is included, and the three sides of one end of the flow channel plate body 1 are respectively provided with threaded holes 2, and the threaded holes are connected with a wear-resistant block, and the wear-resistant block includes an integrally formed The wear-resistant body 3 and the screw 4, the screw 4 is connected in the threaded hole 2; it is convenient to connect and replace the wear-resistant block; at the same time, it can adapt to the processing requirements of different materials;

[0013] The wear-resistant blocks on the three sides are U-shaped and are used to cover the end face of the runner plate body to avoid damage to the working end face. At the same time, the three wear-resistant blocks are convenient for timely replacement of worn wear-resistant blocks; the runner plate body The side of the wear-resistant body is provided with a sawtooth groove 51, and the inner side of the wear-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com