A loop reactor with a guide member

A loop reactor and guide body technology, applied in chemical instruments and methods, mechanical oscillation water/sewage treatment, water/sewage treatment, etc., can solve the problems of low cavitation intensity, difficulty in realizing industrialization, and limitation of ultrasonic cavitation applications. , to achieve the effect of increasing the gas-liquid contact area, easy management, and strengthening the sewage treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

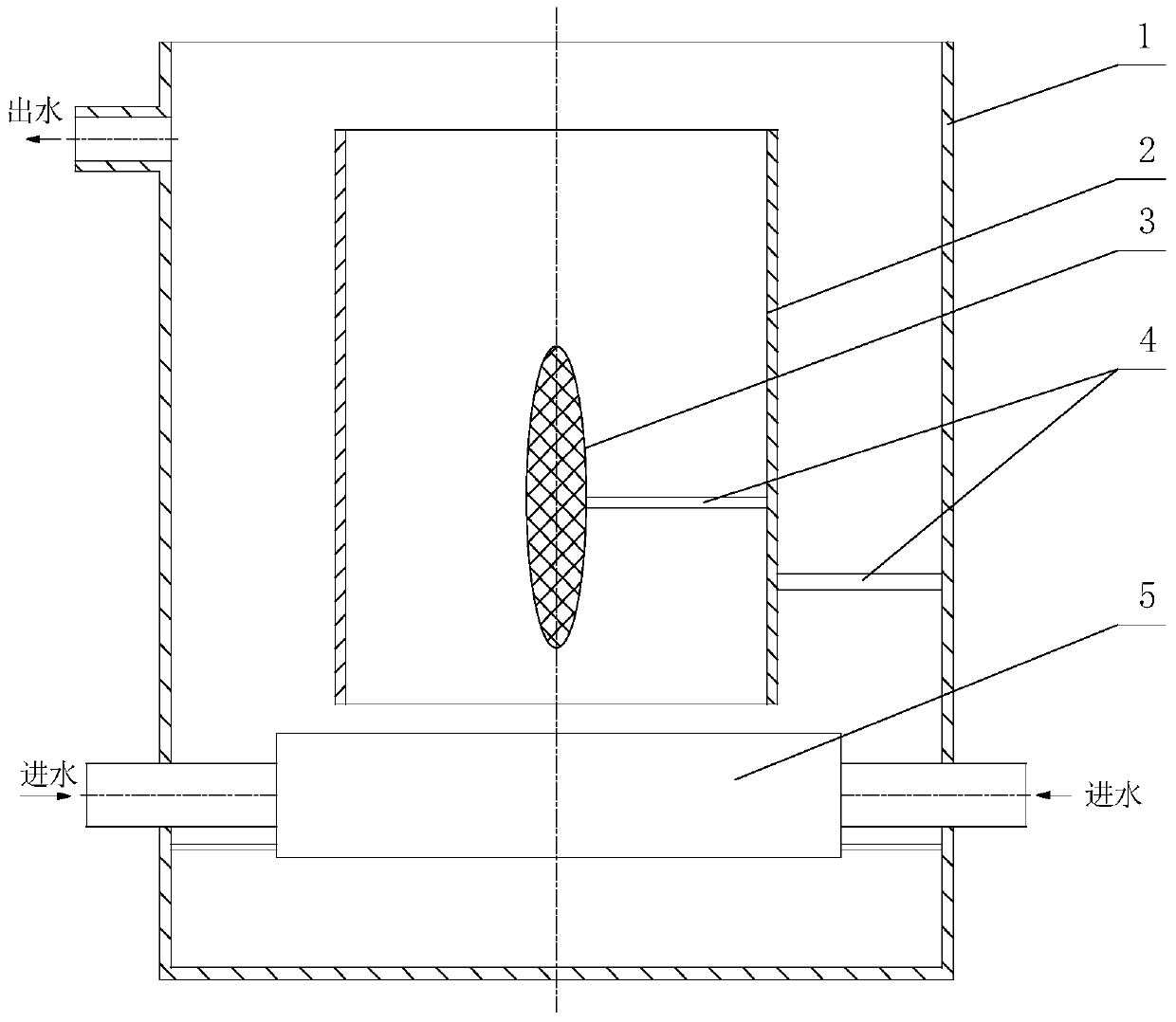

[0022] Depend on figure 1 It can be seen that the loop reactor with the guide member in this embodiment is composed of the outer cylinder 1 , the guide cylinder 2 , the guide 3 , the cavitation nozzle 5 and the fixed rod 4 .

[0023] The outer cylinder 1 of the present embodiment is a cylindrical structure with a diameter of 60 cm, and a water outlet is opened on the upper side wall of the outer cylinder 1, and the inner chamber of the outer cylinder 1 is 45 cm away from the bottom of the outer cylinder 1 through the fixed rod 4 and A guide tube 2 with a diameter of 50 cm is fixedly installed on the threaded fastener. The central axis of the guide tube 2 coincides with the central axis of the outer tube 1. The height of the lower port of the guide tube 2 from the bottom of the outer tube 1 is 20 cm. , a cavitation nozzle 5 is fixedly installed directly below the guide cylinder 2 through a fixed rod 4 welded on the inner wall of the outer cylinder 1, see figure 2 .

[0024] ...

Embodiment 2

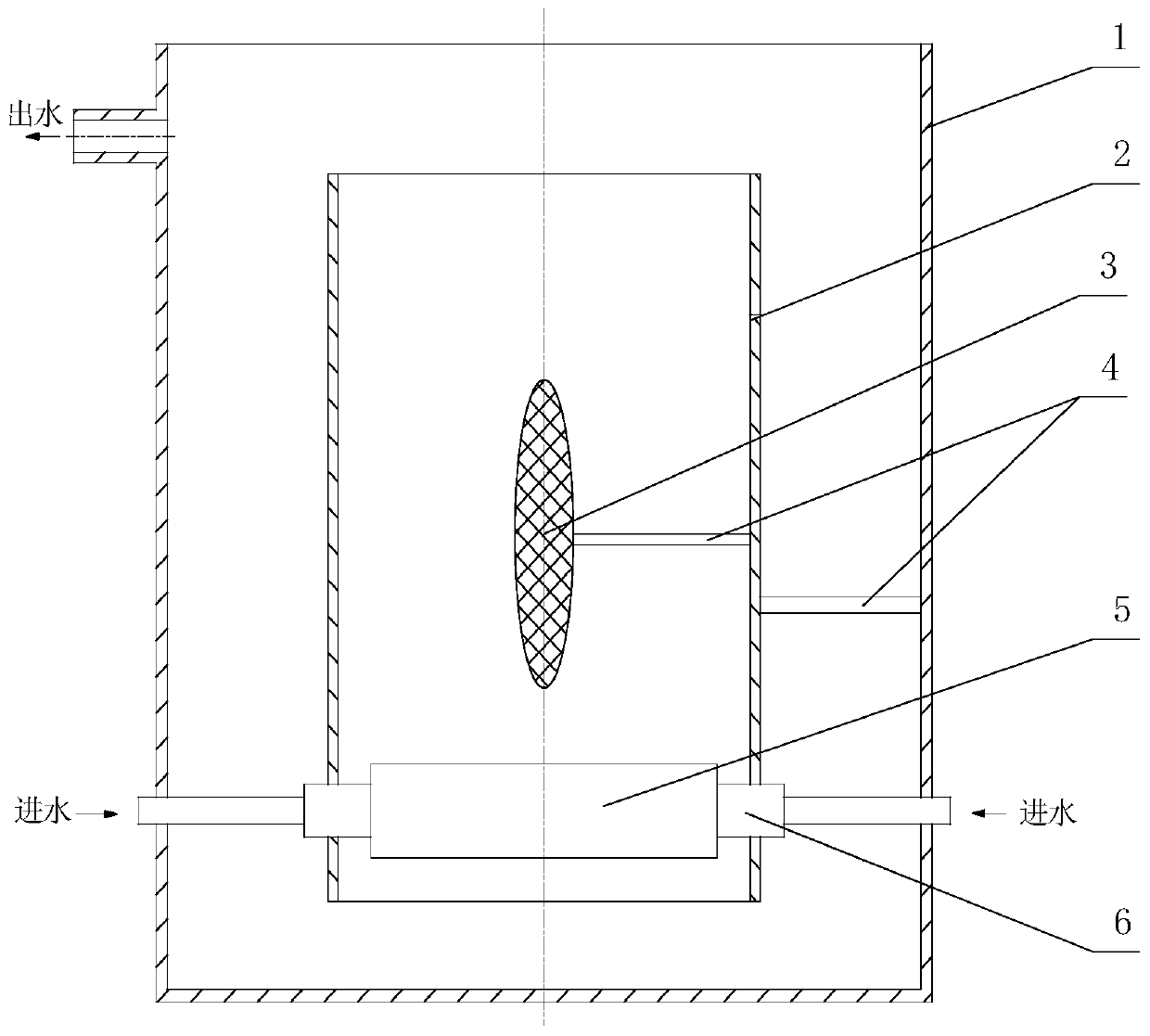

[0030] see figure 2 , in the present embodiment, a guide tube 2 with a diameter of 46 cm is fixedly installed in the inner cavity of the outer cylinder 1 through a fixed rod 4 and a threaded fastener, and the height of the lower port of the guide tube 2 from the bottom of the outer tube 1 is 20 cm. , circular installation holes are processed on the opposite side walls of the guide tube 2 at the bottom end of the guide tube 2, and two oppositely arranged joints 6 are installed on the circular installation holes in a threaded manner, between the joints 6 The space is communicated through the cavitation nozzle 5, and the other ends of the joints 6 are respectively communicated with the water inlet pipes extending to the outside of the outer cylinder 1.

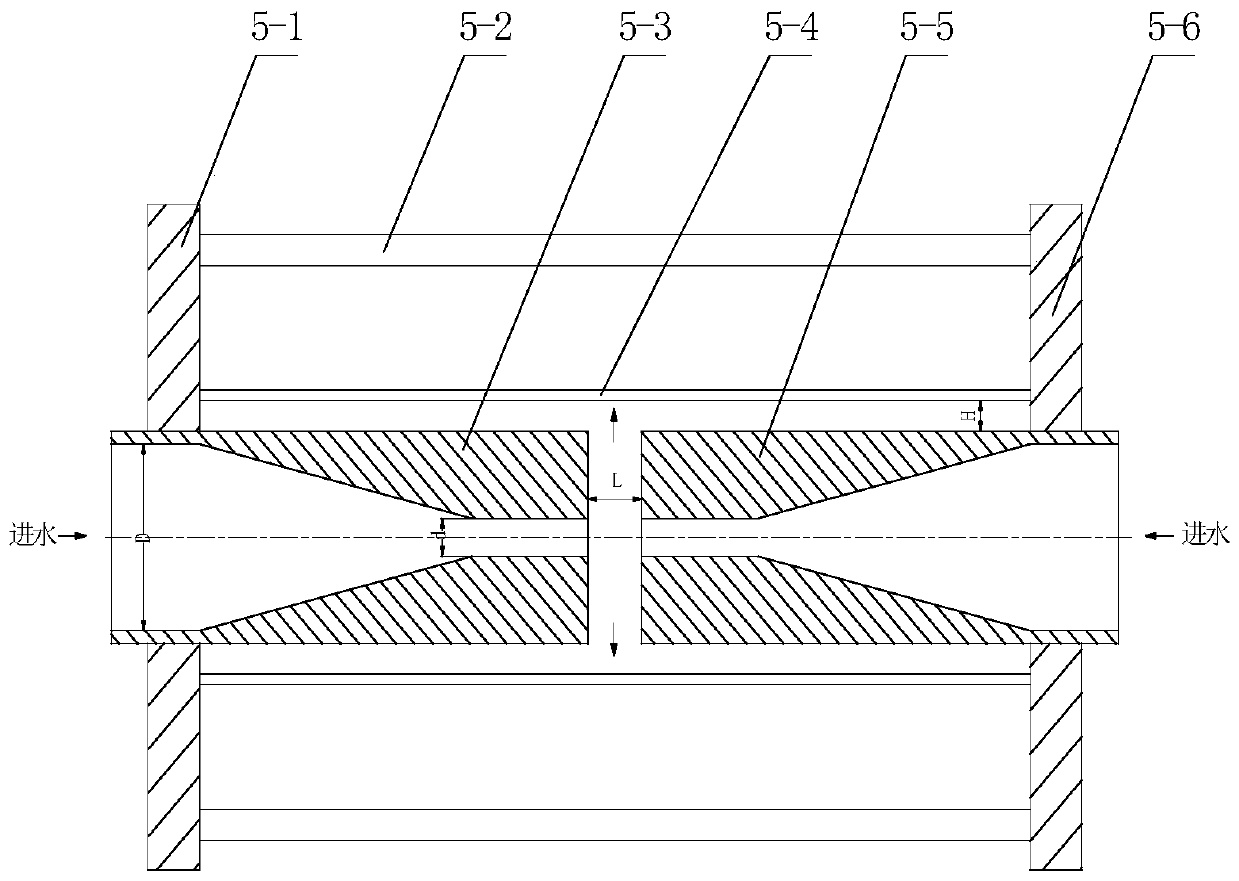

[0031] The cavitation nozzle 5 of this embodiment is composed of a first fixed plate 5-1, a connecting rod 5-2, a first nozzle 5-3, a second fixed plate 5-6, a second nozzle 5-5 and a vibrating rod 5- 4 connection configuration...

Embodiment 3

[0037] In this embodiment, a guide tube 2 with a diameter of 48 cm is fixedly installed in the inner cavity of the outer cylinder 1 through a fixed rod 4 and a threaded fastener. The central axis of the guide tube 2 coincides with the central axis of the outer cylinder 1. A cavitation nozzle 5 is fixedly installed directly below the guide cylinder 2 through a fixed rod 4 welded on the inner wall of the outer cylinder 1 .

[0038] The cavitation nozzle 5 of this embodiment is composed of a first fixed plate 5-1, a connecting rod 5-2, a first nozzle 5-3, a second fixed plate 5-6, a second nozzle 5-5 and a vibrating rod 5- 4 connection configuration. Among them, the connecting rods 5-2 connected by welding between the first fixing plate 5-1 and the second fixing plate 5-6 are fixed, all of which are made of stainless steel. In order to ensure stable connection, the connecting rods 5-2 are distributed on the first The edges of the fixing plate 5-1 and the second fixing plate 5-6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com