Method for improving high-temperature oxidation resistance of TiAl-based alloy by pre-oxidation

A high-temperature anti-oxidation, base alloy technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of destructive mechanical properties, poor plasticity at room temperature, oxidation, etc., and achieve simple process, cheap raw materials and easy The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

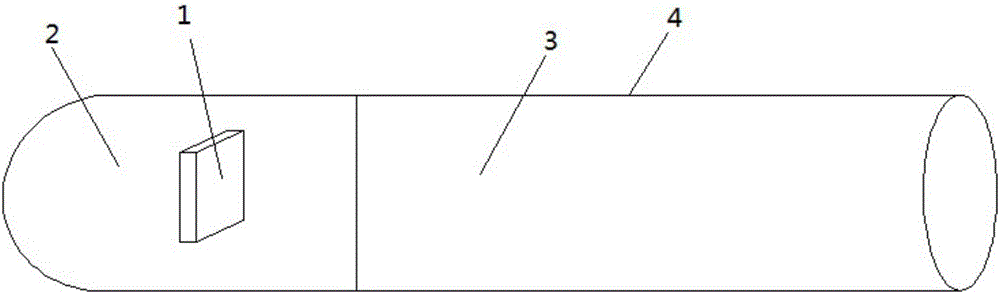

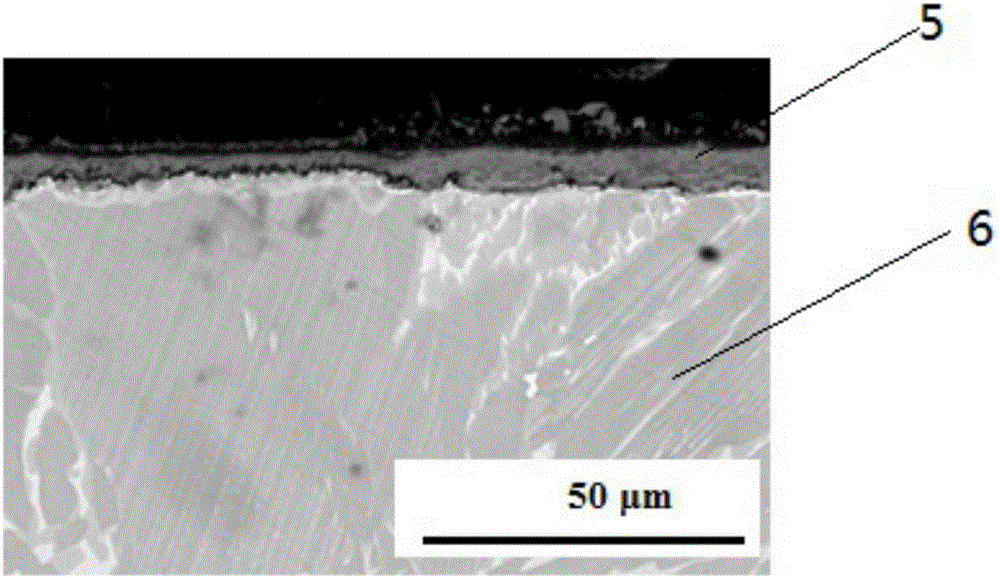

[0034] A method for improving the high-temperature oxidation resistance of a TiAl-based alloy through pre-oxidation, specifically comprising the following steps: cutting the TiAl-based alloy to a suitable size, smoothing it with sandpaper, and cleaning it with acetone to obtain a TiAl-based alloy sample 1, and placing it on a corundum In tube 4, the surface is sequentially buried with Al 2 o 3 Powder layer 2 and Al+Al 2 o 3 Mixed powder layer 3, the mass fraction of Al powder in the mixed powder layer is 30%, the specific embedding method see figure 1 , put the corundum tube 4 covered with the sample in a tube furnace, vacuumize the tube furnace and fill it with high-purity argon, after three cycles, the furnace maintains a state of high-purity argon under an atmospheric pressure; the tube furnace Raise the temperature to 950°C at a heating rate of 8K / min, hold it for 10h, and cool the sample with the furnace, forming a layer of dense Al on the surface of the TiAl-based all...

Embodiment 2

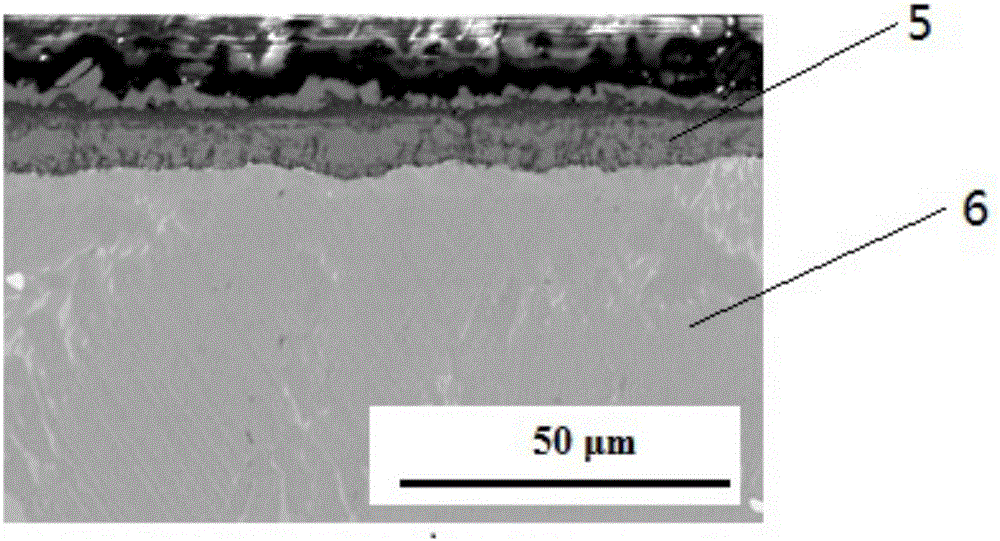

[0037] This embodiment is basically the same as Embodiment 1, the difference is that the Al+Al of this embodiment 2 o 3 The mass content of Al powder in the mixed powder layer is 50%. The sample prepared in this example was subjected to a constant temperature oxidation experiment at 900°C for 100 h in a muffle furnace, and it was found that the oxidation weight gain of the pre-oxidized sample was 1.6442 mg / cm after 100 h 2 .

Embodiment 3

[0039] This embodiment is basically the same as Embodiment 1, the difference is that the Al+Al of this embodiment 2 o 3 The mass content of Al powder in the mixed powder layer is 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxidative weight gain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com