Porous lead rubber bearing with high damping capacity and large bearing capacity

A technology of lead-core rubber bearings and bearing capacity, which is applied to bridge parts, building components, bridges, etc., can solve the problems of low tensile bearing capacity, poor stability of single bearings, insufficient use of lead damping, etc., and achieve damping distribution Uniformity, strong shock absorption effect, and enhanced structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

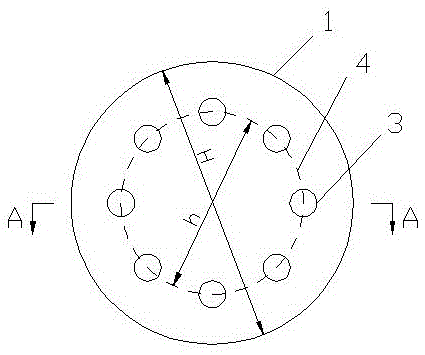

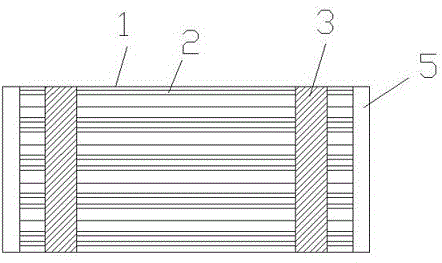

[0020] A porous lead rubber bearing with high damping and large bearing capacity, refer to figure 1 and figure 2 , the support is cylindrical, and it includes a plurality of steel plate layers 1 and rubber layers 2 with the same diameter and arranged alternately from top to bottom, and the uppermost layer and the lowermost layer of the support are both steel plate layers 1 . It also includes cylindrical lead cores 3 that run through all the steel plate layers 1 and rubber layers 2. The number of the lead cores is multiple and uniformly arranged along the circumferential direction of the support. The centers of all the lead cores 3 are located at the virtual concentric position of the same support On the circle 4, the diameter h of the virtual concentric circle 4 is 56%-66% of the diameter H of the support. A rubber protection layer 5 is wrapped on the outer surfaces of the steel plate layer 1 and the rubber layer 2 .

[0021] In this embodiment, the lead cores 3 are evenly ...

Embodiment 2

[0023] The difference between this embodiment and the first embodiment is that the number of lead cores 3 is 8-10. The simulation results show that when the diameter of the concentric circle where the lead core is located remains unchanged (that is, the circumferential position of the lead core remains unchanged), the number of lead cores is increased and the cross-sectional area of a single lead core is reduced (the total cross-sectional area of the lead core needs to be kept constant, Because the ratio between the area of the lead core and the area of the support should comply with industry standards). Experiments have shown that with the increase of the number of lead cores, the energy dissipation capacity of the isolation bearing increases, but the growth rate of the energy dissipation capacity of the isolation bearing becomes slower and slower with the increase of the number of lead cores. Too many lead cores will cause processing costs and other problems. Therefo...

Embodiment 3

[0025] The difference between this embodiment and the second embodiment is that the distance between the outer edge of each lead core 3 and the outer edge of the support is not less than 10% of the radius of the cross section of the support, and is not less than the radius of a single lead core.

[0026] From the simulation results, the distance between the outer edge of the lead core and the outer edge of the rubber isolation layer should not be less than 10% of the radius of the rubber layer, and should not be less than the radius of a single lead core, so as not to cause uneven stress distribution at the end and reduce the Working stability of a single isolator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com