Method for analyzing and determining methyl trifluoropyruvate

A technology of methyl trifluoropyruvate and methyl pyruvate, applied in the field of analysis and determination of methyl trifluoropyruvate, can solve the problems of expensive instruments, unsuitable for routine analysis of enterprises, difficult quantitative analysis, etc., and the method is simple , Test the effect of low price and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

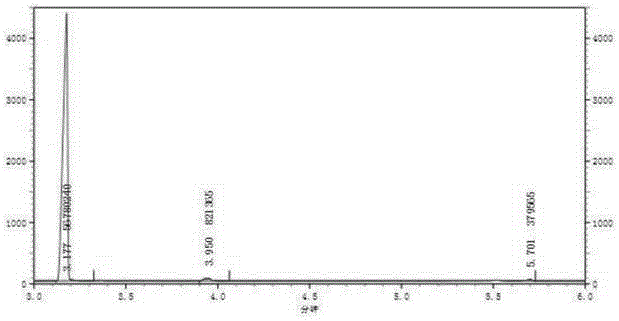

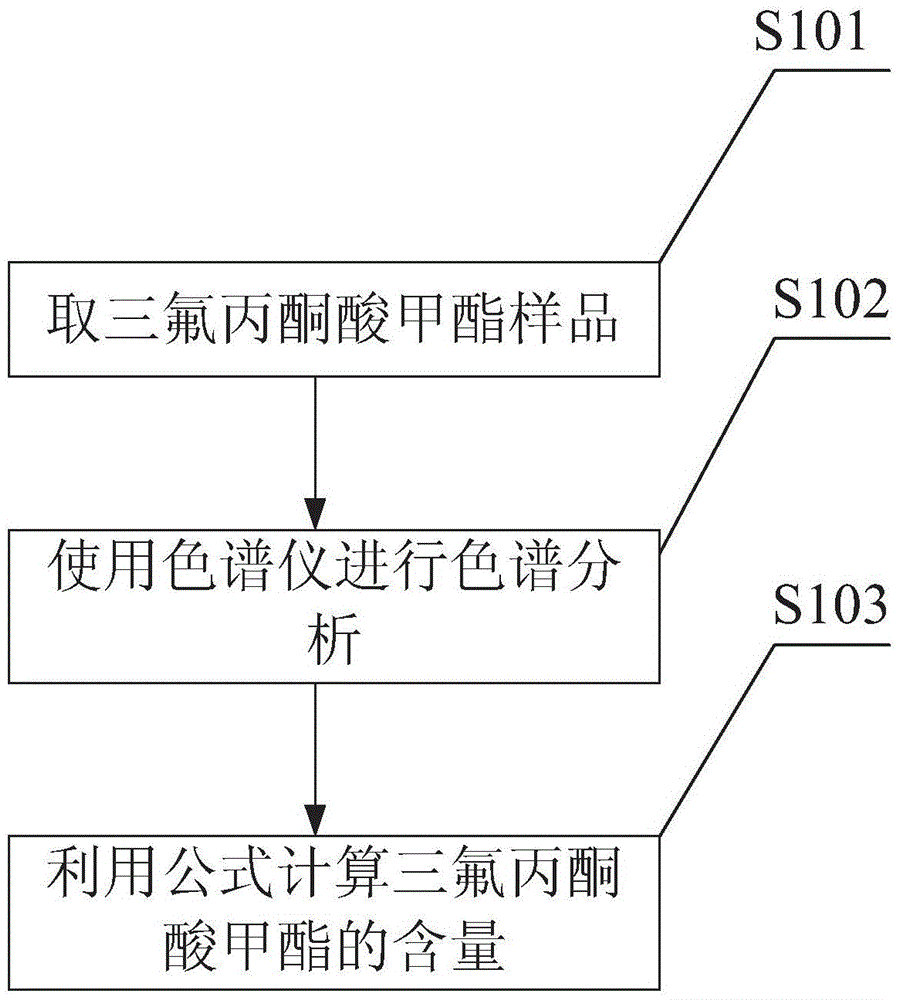

[0023] as attached figure 1 And attached figure 2 shown

[0024] The invention provides a method for the analysis and determination of methyl trifluoropyruvate. The methyl trifluoropyruvate is analyzed by gas chromatography, and the content of methyl trifluoropyruvate is directly quantitatively determined by the area normalization method, which specifically includes the following steps:

[0025] S101: Take a sample of methyl trifluoropyruvate;

[0026] S102: use a chromatograph for chromatographic analysis;

[0027] S103: Using a formula to calculate the content of methyl trifluoropyruvate.

[0028] Further, in S101, 0.2 uL of methyl trifluoropyruvate sample is specifically taken.

[0029] Further, in S102, the 0.2 uL sample of methyl trifluoropyruvate that was taken out was subjected to chromatographic analysis with a chromatographic instrument, and the chromatographic analysis temperature rise program specifically adopted an initial temperature of 40°C, kept for 1min, a...

specific Embodiment

[0037] instrument

[0038] Agilent 7820 chromatograph produced in the United States

[0039] Chromatographic conditions

[0040] Detector: FID (Flame Ionization Detector)

[0041] Column: HP-5

[0042] Split ratio: 100:1

[0043] Gas velocity: 2mL / min

[0044] Column temperature rise program: 40°C / 1min→10°C / min→260°C / 1min

[0045] Injector: 250°C

[0046] Detector: 250°C

[0047] sample analysis

[0048] Sampling 0.2uL was carried out chromatographic analysis, and the content of methyl trifluoropyruvate was obtained according to the following formula.

[0049] Methyl trifluoropyruvate (%)=A / ∑A(1)

[0050] In the formula: A is the peak area of methyl trifluoropyruvate

[0051] ΣA is the total area of each peak.

[0052] Such as figure 1 Among them, the peak area of methyl trifluoropyruvate is 56780240, the peak area of hydrate is 379565, and the peak area of methyl trifluoroacetate is 821365, so the content of methyl trifluoropyruvate is:

[0053] Peak ar...

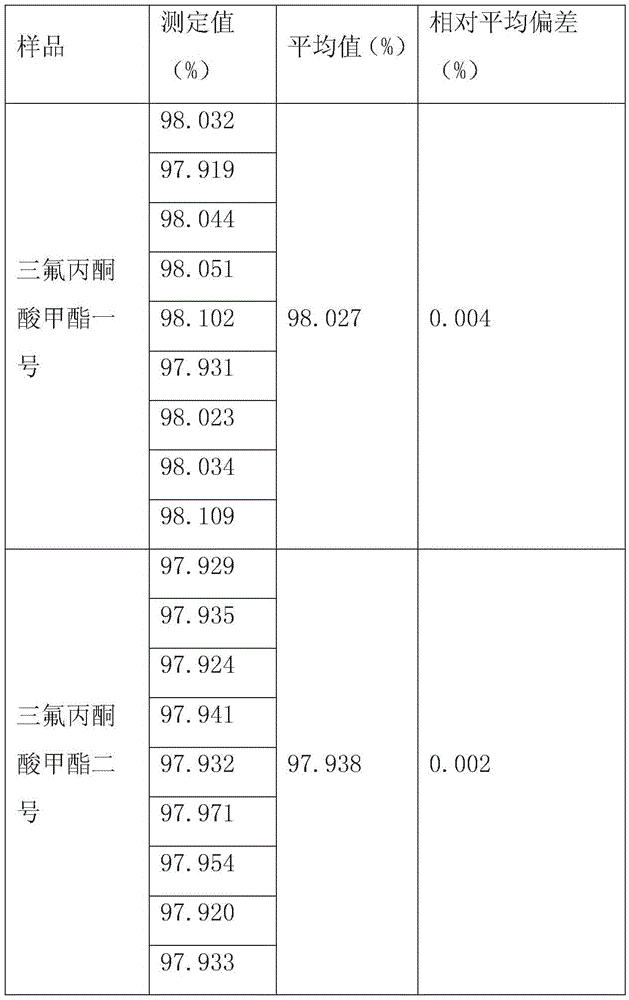

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com