Gas phase nicotine calibrating apparatus and method thereof

A calibration device and nicotine technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of collection, analysis and detection, and achieve the effects of improved accuracy, easy operation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The device of the present invention will be further described below in conjunction with the accompanying drawings:

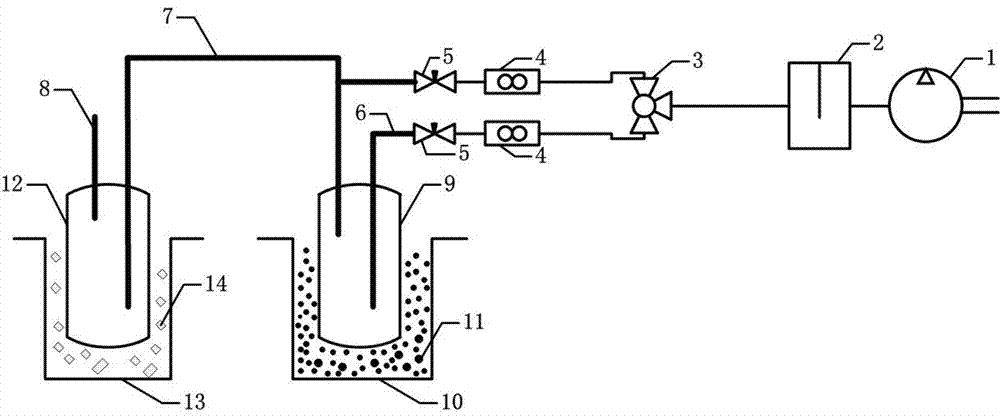

[0024] Such as figure 1 As shown: a gas-phase nicotine calibration device, including an air compressor 1, a steam-water separator 2 connected through pipelines, an upper and lower gas circuit divided into two paths through a three-way valve 3, a closed high-temperature evaporation chamber 9 and Closed low-temperature condensation chamber 12, a button-shaped tube is inserted between the closed-type high-temperature evaporation chamber and the closed-type low-temperature condensation chamber, and the button-shaped tube is composed of a horizontal tube and vertical tubes extending downward along both ends of the horizontal tube , and the mouth of the vertical tube of the button tube located in the evaporation chamber is located above the liquid surface, the mouth of the vertical tube of the button tube located in the condensation chamber is located below the...

Embodiment 2

[0030] Further description will be given below in conjunction with the evaporation of nicotine in the nicotine-propylene glycol system under different temperature conditions.

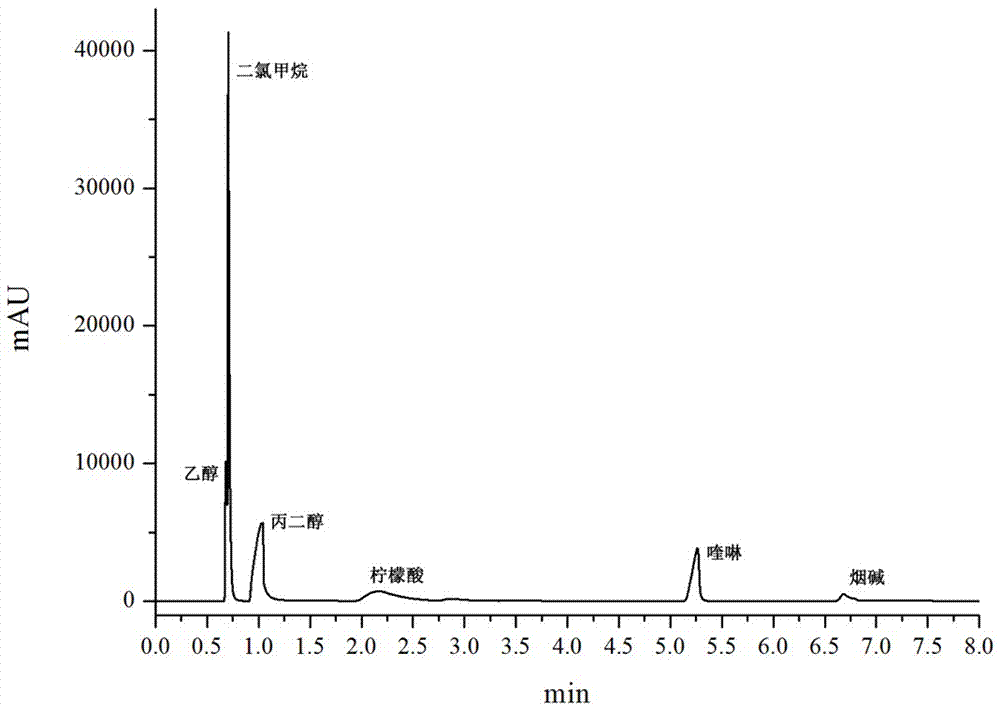

[0031] combined with figure 2 For further clarification:

[0032] The figure is a gas chromatogram of a gas-phase nicotine solution obtained by evaporating at 70° C. for four hours by the method of the present invention. The substance at the retention time of 5.276min is the internal standard quinoline, the substance at the retention time of 6.688min is nicotine, and the addition amount of the internal standard quinoline is 21.86μg, so the quality of nicotine obtained is about 4.17μg, as shown in the following table:

[0033] name

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com