Laser projection device

A technology of laser projection and equipment, applied in the field of projection, can solve the problems of low cooling efficiency, deformation of light-transmitting mirror, damage to laser light source components, etc., and achieve the effects of improving heat dissipation efficiency, simplifying structure, and improving dust resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the embodiment of the present invention, the components of the laser projection device include at least two parts: a first part: a heat source component; a second part: a power board and / or a driving board. Wherein, the heat source component includes at least a laser light source component and an optomechanical component.

[0038] Optionally, the laser light source component is a closed structure that is closed with a first casing. Optionally, the optomechanical component is a closed structure that is sealed by a second casing.

[0039] Optionally, the laser light source component includes at least a laser and a fluorescent wheel. Optionally, the laser light source component further includes a first optical lens. Optionally, the optomechanical component includes at least a digital micromirror device (DigitalMicromirrorDevice, DMD for short). Optionally, the optomechanical component further includes a second optical lens.

[0040] In laser projection equipment, th...

Embodiment 2

[0090] Based on the same idea, an embodiment of the present invention also provides a laser projection device.

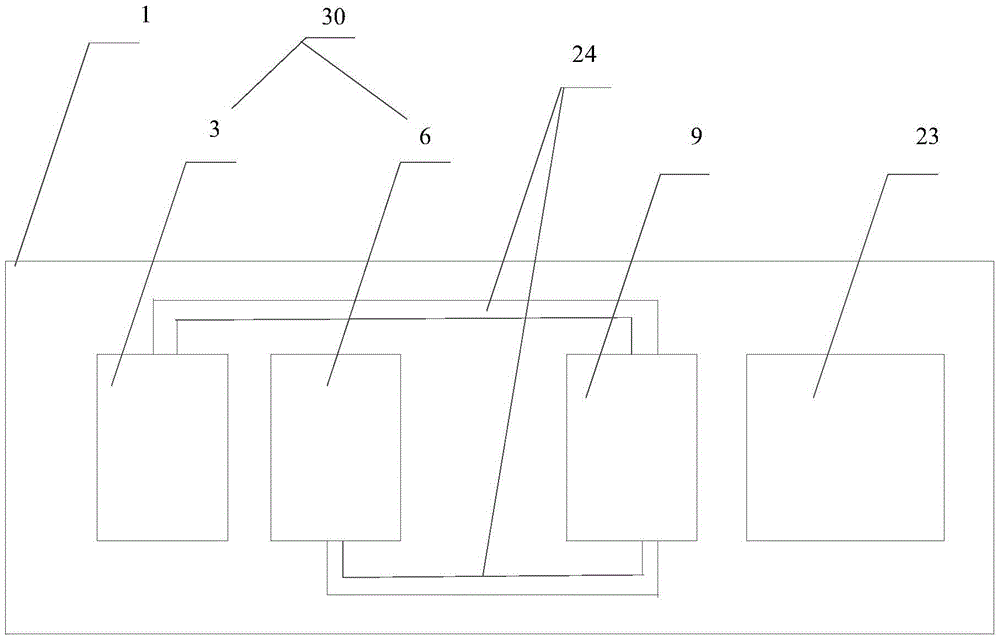

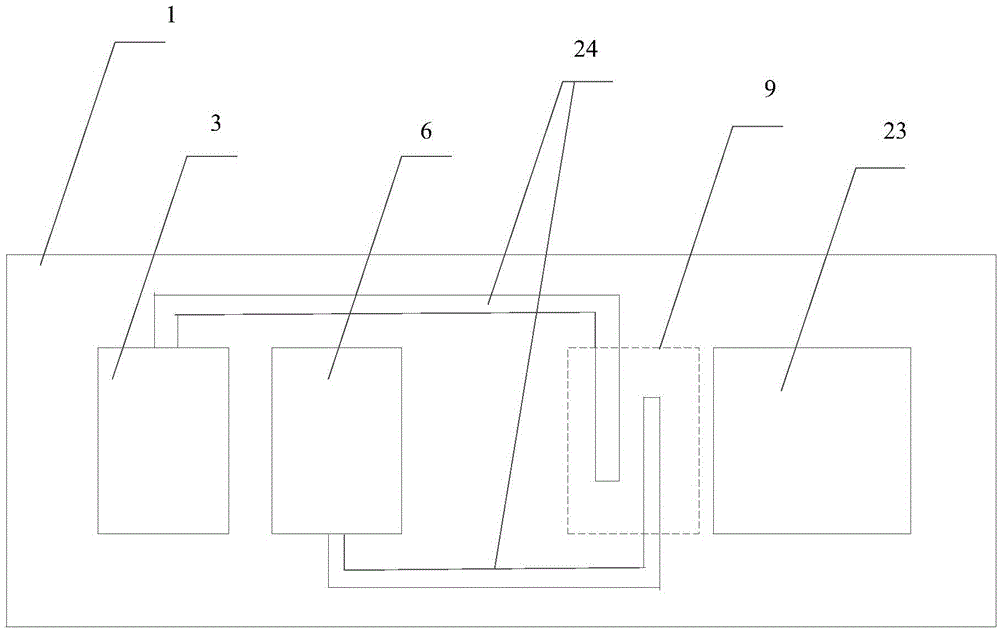

[0091] Figure 3a A schematic diagram of a laser projection device applicable to an embodiment of the present invention is exemplarily shown, such as Figure 3a As shown, the laser projection device provided by the embodiment of the present invention includes:

[0092] A heat source component; the heat source component includes at least a laser light source component and an optomechanical component; wherein, the laser light source component includes a sealed casing outside; the laser light source component is a closed structure that is sealed by the first casing;

[0093] A heat pipe, one end of the heat pipe is connected to the heat source part, and the other end is connected to the heat concentration module; it is used to export the heat generated by each part of the heat source part to the heat concentration module;

[0094] The heat concentration module is loc...

Embodiment 3

[0110] Based on the same idea, an embodiment of the present invention provides a laser projection device. The laser projection device provided in the third embodiment is applicable to the laser projection device provided in the first embodiment above, and is also applicable to the laser projection device provided in the second embodiment above. That is to say, optionally, the laser light source component in the laser projection device provided in the third embodiment may or may not include a sealed casing.

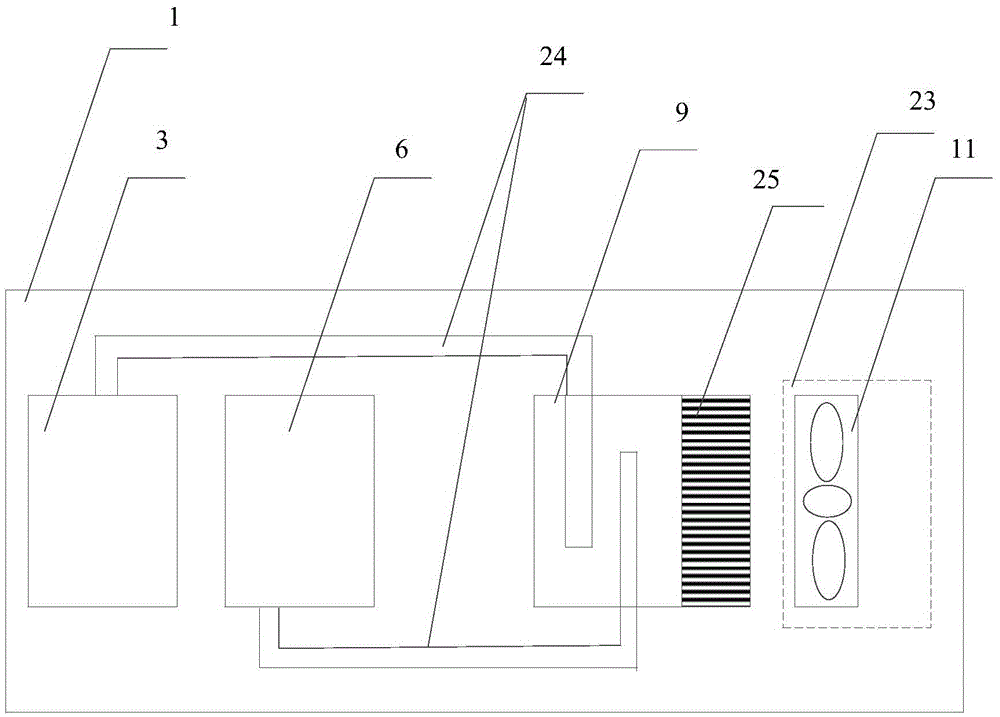

[0111] Figure 4a A schematic structural diagram of a laser projection device provided by an embodiment of the present invention is shown as an example. Such as Figure 4a As shown, laser projection equipment includes:

[0112] Heat source components; heat source components include at least laser light source components and optomechanical components;

[0113] A heat pipe, one end of the heat pipe is connected to the heat source part, and the other end is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com